Transmission device of having nutation oscillating tooth

A technology of movable tooth transmission and moving disc, which is applied in transmission devices, friction transmission devices, belts/chains/gears, etc., and can solve problems such as low load capacity, complex structure, and low transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

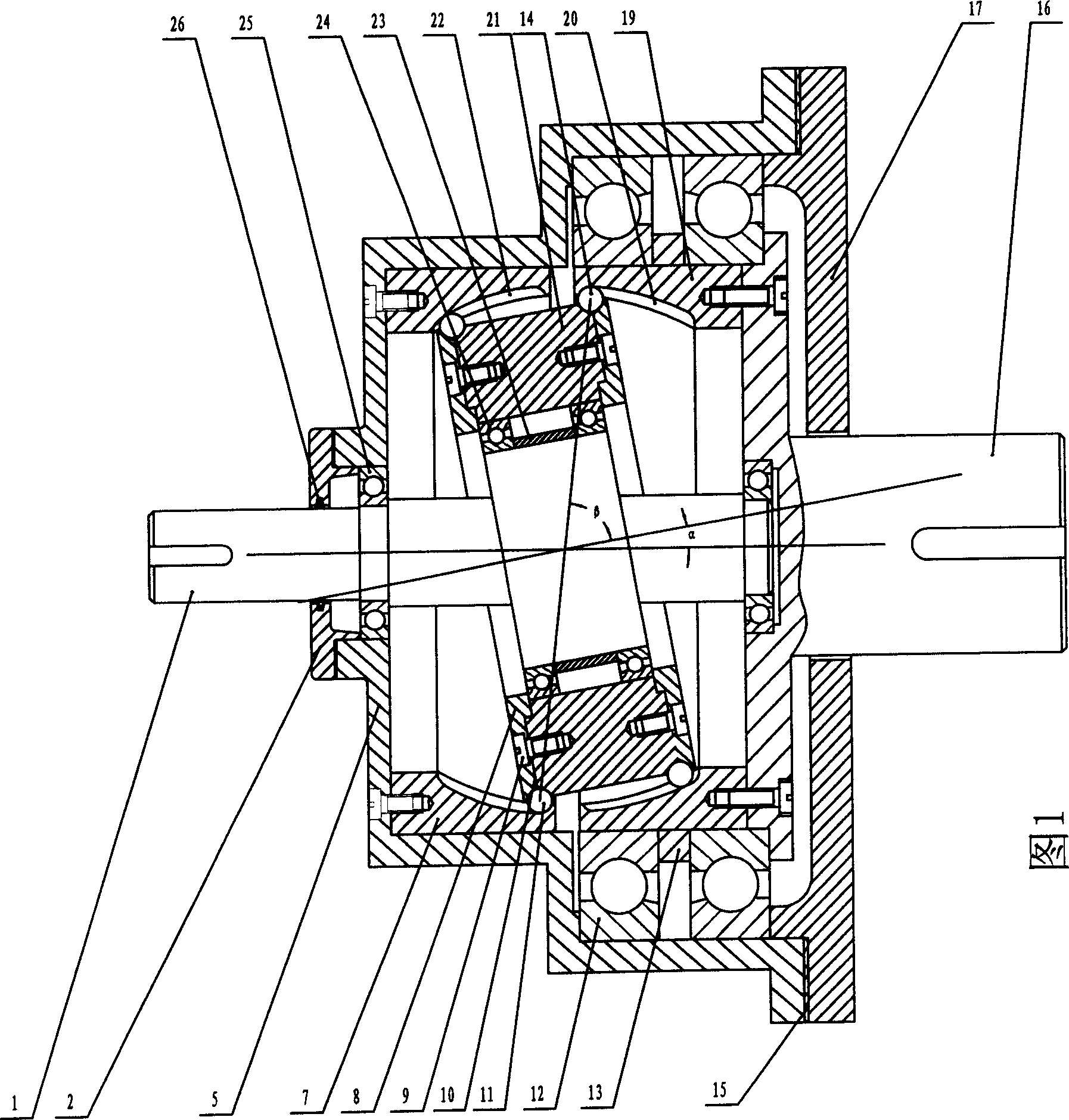

[0023] As shown in Figure 1, the structure of the nutating movable tooth transmission device of the present invention, wherein the nutating movable tooth transmission device includes the input shaft 1 inserted in the end cover 2 and the machine base 5 supported by the support bearing 25, and the input shaft 1 inserted in the bearing The output shaft 16 in the end cover 17; the end cover 2 and the bearing end cover 17 are fixed on the machine base 5 by screws, the connection part of the end cover and the machine base is provided with a gasket 15, and the connection position of the end cover 2 and the input shaft 1 Sealed by sealing ring 26 . The position of the offset shaft section of the input shaft 1 is connected with a nutating disk 21 through a bearing. The position of the offset shaft section of the input shaft can be integrated with the input shaft in order to reduce costs and ensure processing efficiency during mass production; it can also be realized by setting an offse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com