Method of preparing superfie fiber formulation for carmustine

A technology of ultrafine fiber and carmustine, which is applied in fiber treatment, filament/thread forming, single-component polyester artificial filament, etc., can solve the problems of poor clinical effect and achieve stable drug release behavior and residual low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1. 0.7768g of L-polylactic acid PLLA (number average molecular weight 86400) is dissolved in the mixed solvent of 4ml chloroform and 1ml acetone, after fully dissolving, add 39mg carmustine again, stir to make it fully dissolve, form uniform mixing solution. Then the mixed solution was added to a 10ml syringe, and a right-angled flat-mouthed spinneret made of No. 8 needle was adopted. The spinning flow rate was 2ml / h, the applied voltage was 35kV, and the distance between the two poles was 24cm.

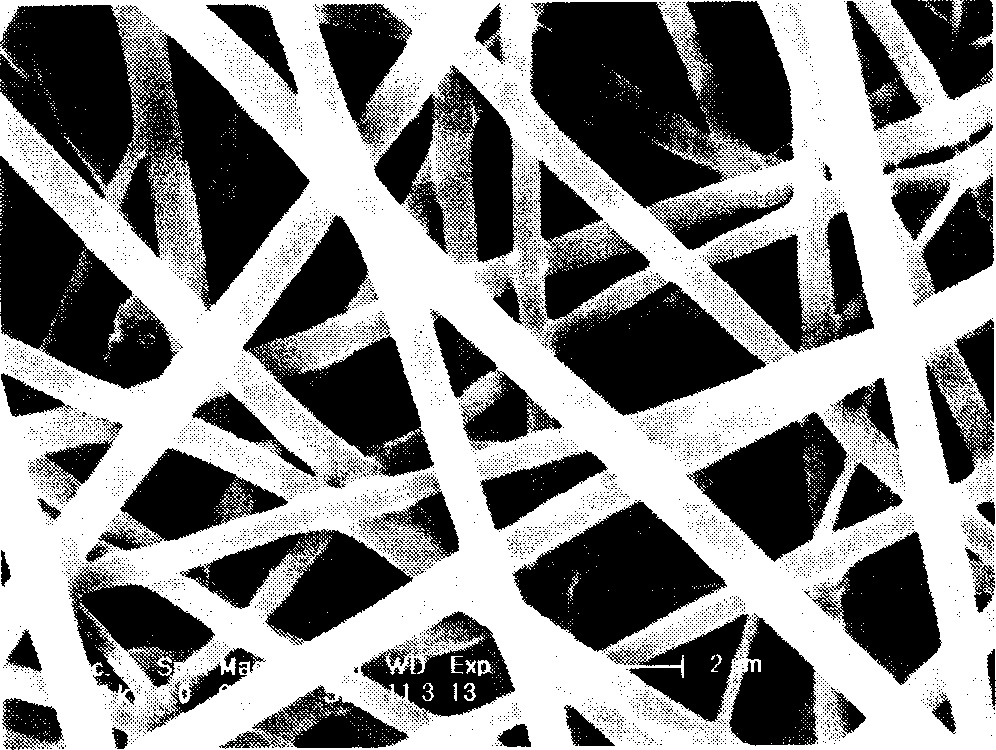

[0020] The mean diameter 500nm of gained drug-loaded fiber, carmustine content 5%, see figure 1 .

Embodiment 2

[0021] Embodiment 2. is dissolved in 5ml chloroform with the random copolymer PLGA (wherein mass composition lactide 80%, glycolide 20%, number average molecular weight 79500) of 0.9616g lactide and glycolide, after fully dissolving , then add 96mg carmustine, stir to make it fully dissolved, and form a uniform mixed solution. Then the mixed solution was electrospun, using a right-angle flat nozzle made of No. 8 needle, the spinning flow rate was 1.5ml / h, the applied voltage was 33kV, and the distance between the two poles was 18cm.

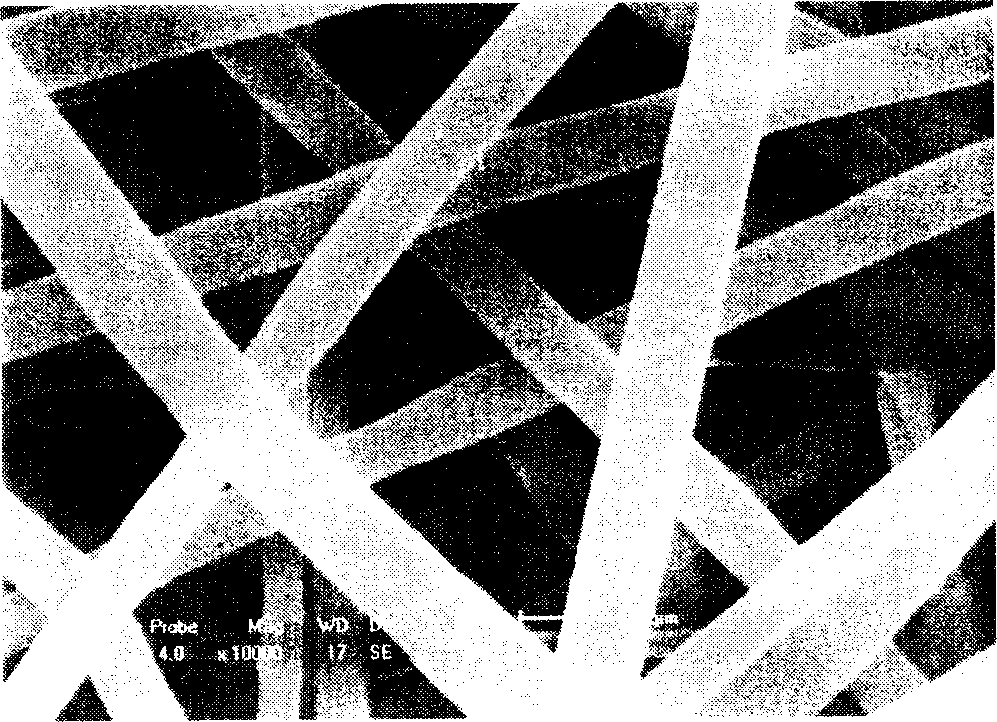

[0022] The average diameter of the obtained drug-loaded fiber is 1.8 μm, and the carmustine content is 10%, see figure 2 .

Embodiment 3

[0023] Embodiment 3. 0.6874g PLLA-PEG block copolymer (number-average molecular weight is 97600, and wherein PEG section number-average molecular weight is 5000) is dissolved in 5ml chloroform, after fully dissolving, add 0.1375g carmustine again, stir to make it Fully dissolved to form a uniform mixed solution. Then the mixed solution was electrospun, using a right-angle flat nozzle made of No. 8 needle, the spinning flow rate was 1.8ml / h, the applied voltage was 35kV, and the distance between the two poles was 24cm.

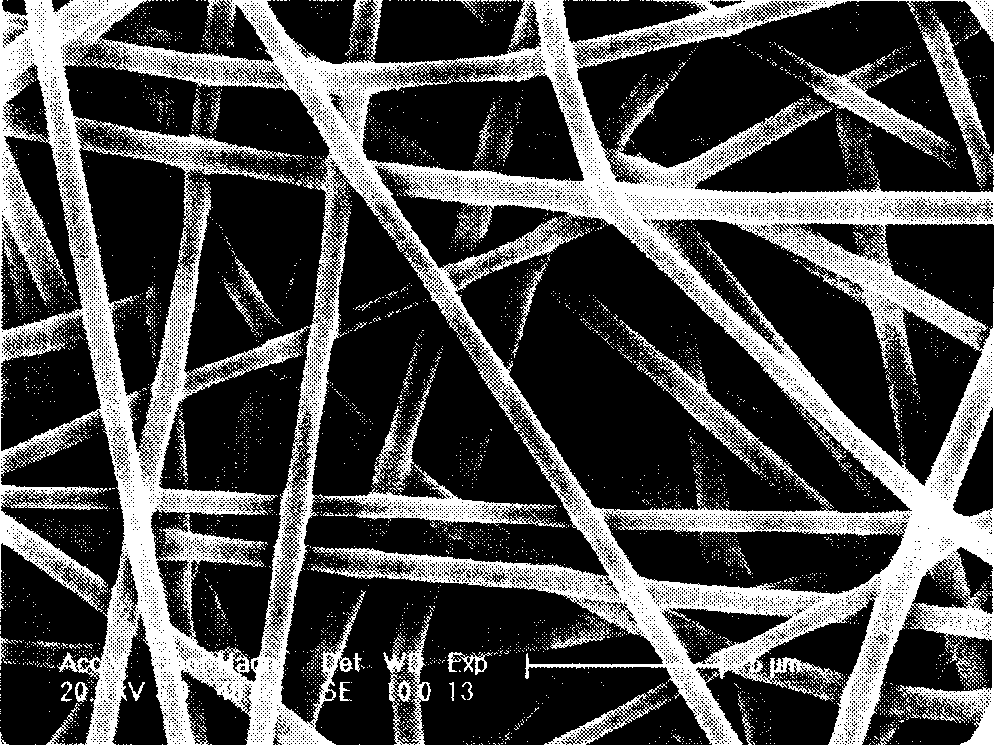

[0024] The average diameter of the obtained drug-loaded fiber is 800nm, and the content of carmustine is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com