Gas heating method and gas heating device

A gas heating and equipment technology, applied in lighting and heating equipment, air heaters, fluid heaters, etc., can solve the problems of large power loss, ineffective heating of flowing gas, and easy to be corroded by gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

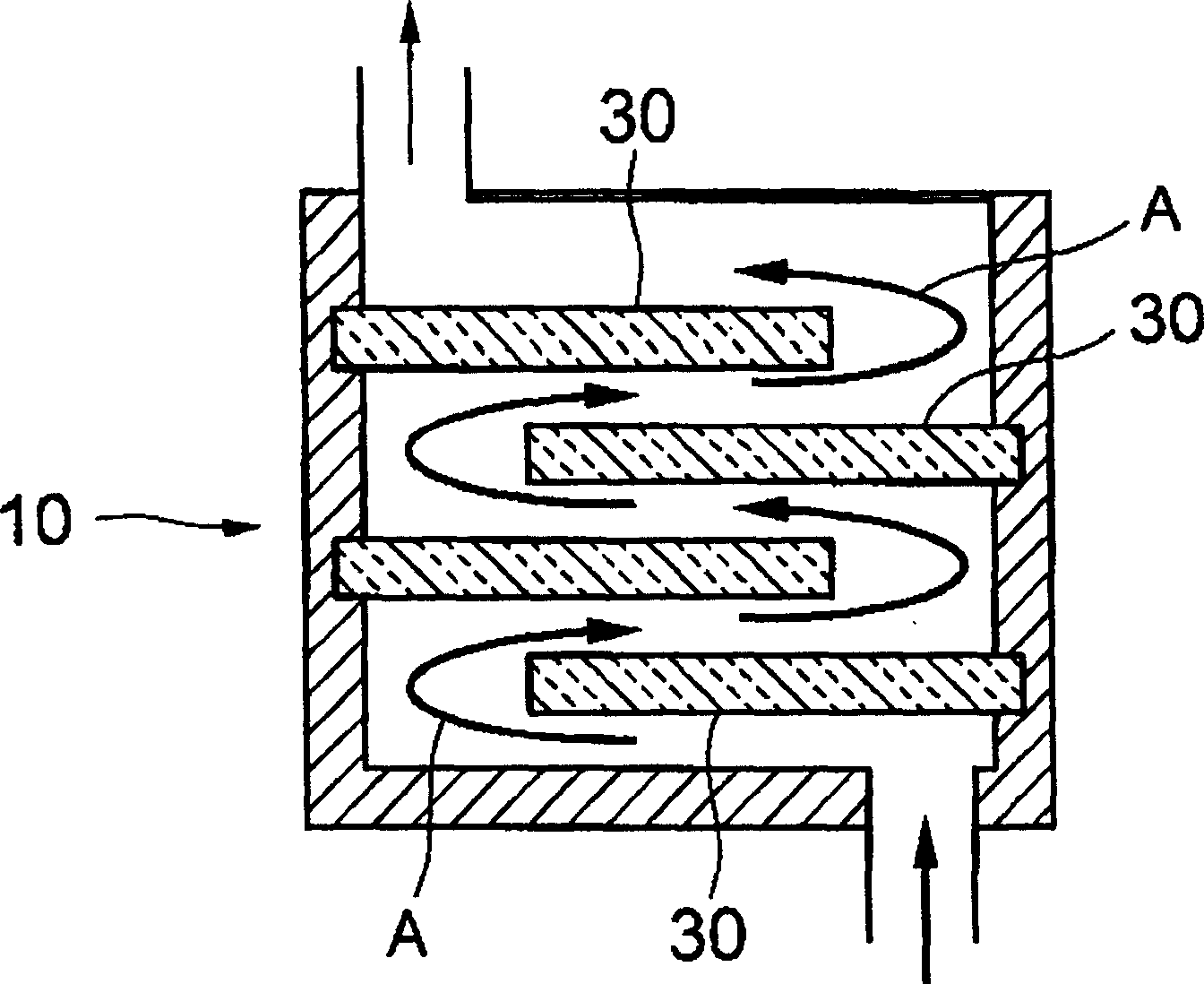

[0050] The gas heating device according to the invention is used in a device for treating harmful exhaust gases, which is used in sterilization and disinfection processes in hospitals. In particular, as Figure 7 As shown, there are four heater assemblies 35, four ceramic heaters are combined in each heater assembly, and the heater assemblies are arranged in the housing 23 in the form of staggered ledges, so that the housing 23 A zigzag gas flow path is formed in the center, thereby serving as the heating device 22 for heating the harmful exhaust gas supplied through the harmful gas introduction port 22a.

[0051] Specifically, the heating device 22 is equipped with a shell 23 made of SUS steel, and the interior of the shell is 430mm x 430mm x 480mm high; internally so as to form staggered ledges spaced 90mm apart from each other. Here, the structure of each heater assembly 35 is as follows Figure 5 One structure shown: four ceramic heaters 30 assembled into a flat planar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com