Production of chitose from fusarium solani

A technology of Fusarium solani and chitosan oligosaccharide is applied in the field of producing high-activity chitosan oligosaccharide, which can solve the problems of difficulty in obtaining, separation and purification, and high production cost, and achieves high enzymatic hydrolysis substrate concentration, high biological activity, and high production cost. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

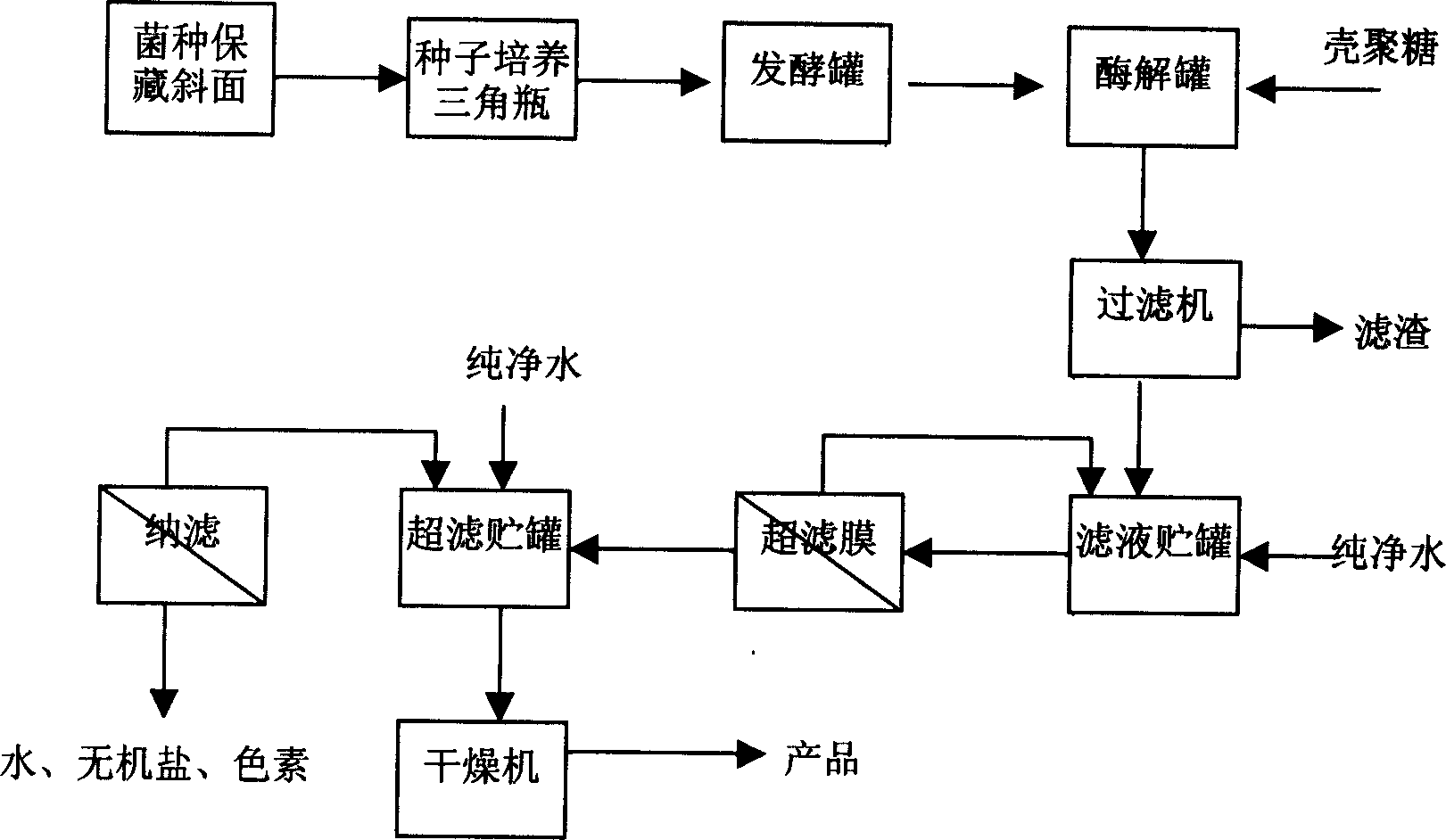

Image

Examples

Embodiment Construction

[0025] This kind utilizes Fusarium solani to produce the method for chitosan oligosaccharide, and its steps comprise:

[0026] 1), using Fusarium solani (Fusarium solani) to produce chitosan high-efficiency endonuclease through culture and fermentation:

[0027] Through rapid screening of plates and shake flask experiments, a strain of Fusarium solani that can rapidly degrade chitosan into chitooligosaccharides was screened; the strain was optimized to ferment chitooligosaccharides above 300U / L. carbohydrase activity;

[0028] Medium composition: glucose 2%, peptone 1%, yeast powder 0.1%, casein 0.1%; medium pH value 5.5-7.5, optimal pH value 6.0; culture time 20-64hr, optimal 60hr; selected The stirring speed is 250-300r / min; the ventilation rate: at 0-24hr, the ventilation ratio is 0.33:1; at 24-48hr, the ventilation ratio is 0.38:1; at the end of 48hr, the ventilation ratio is 0.44:1; and according to the fermentation If necessary, add polyether defoamer in time.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com