Catalysts for polymerization or copolymerization of alpha-olefins, catalyst components thereof, and processes for polymerization of alpha-olefins with the catalysts

A technology for olefin polymerization and catalysts, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of gel formation, melt mixing difficulties, and insufficient hydrogen response And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

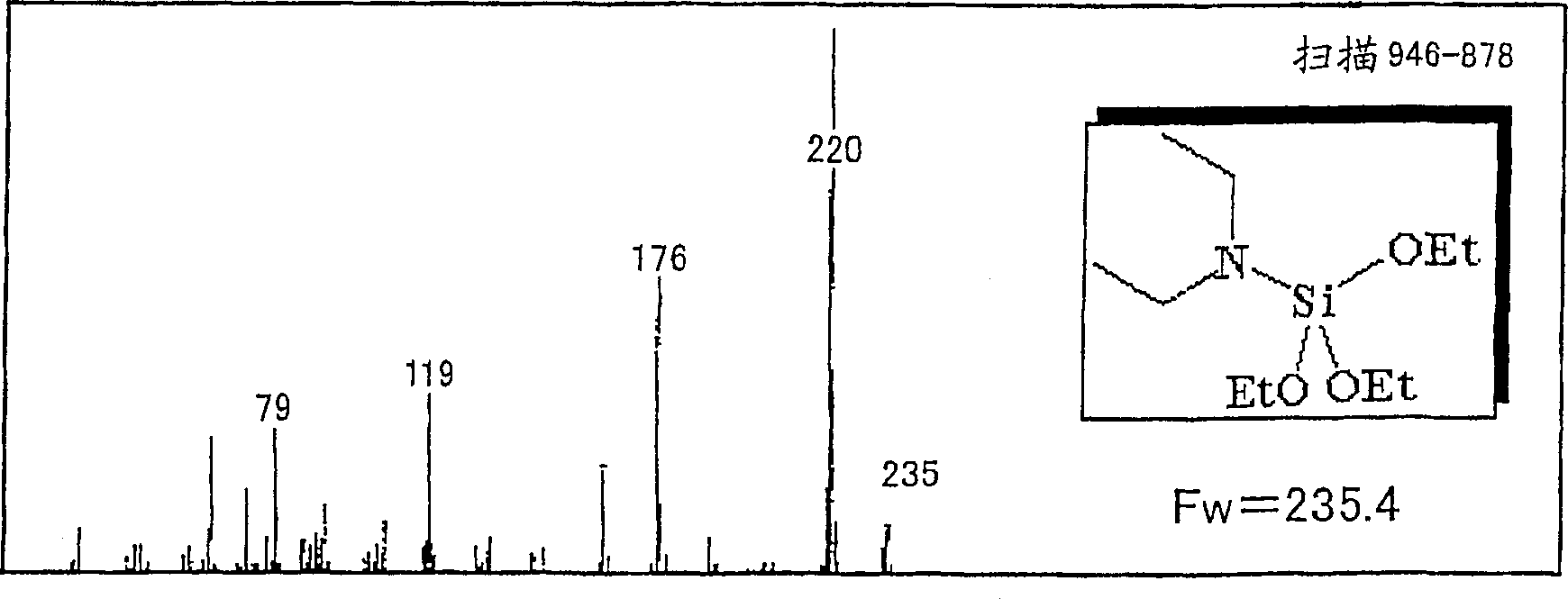

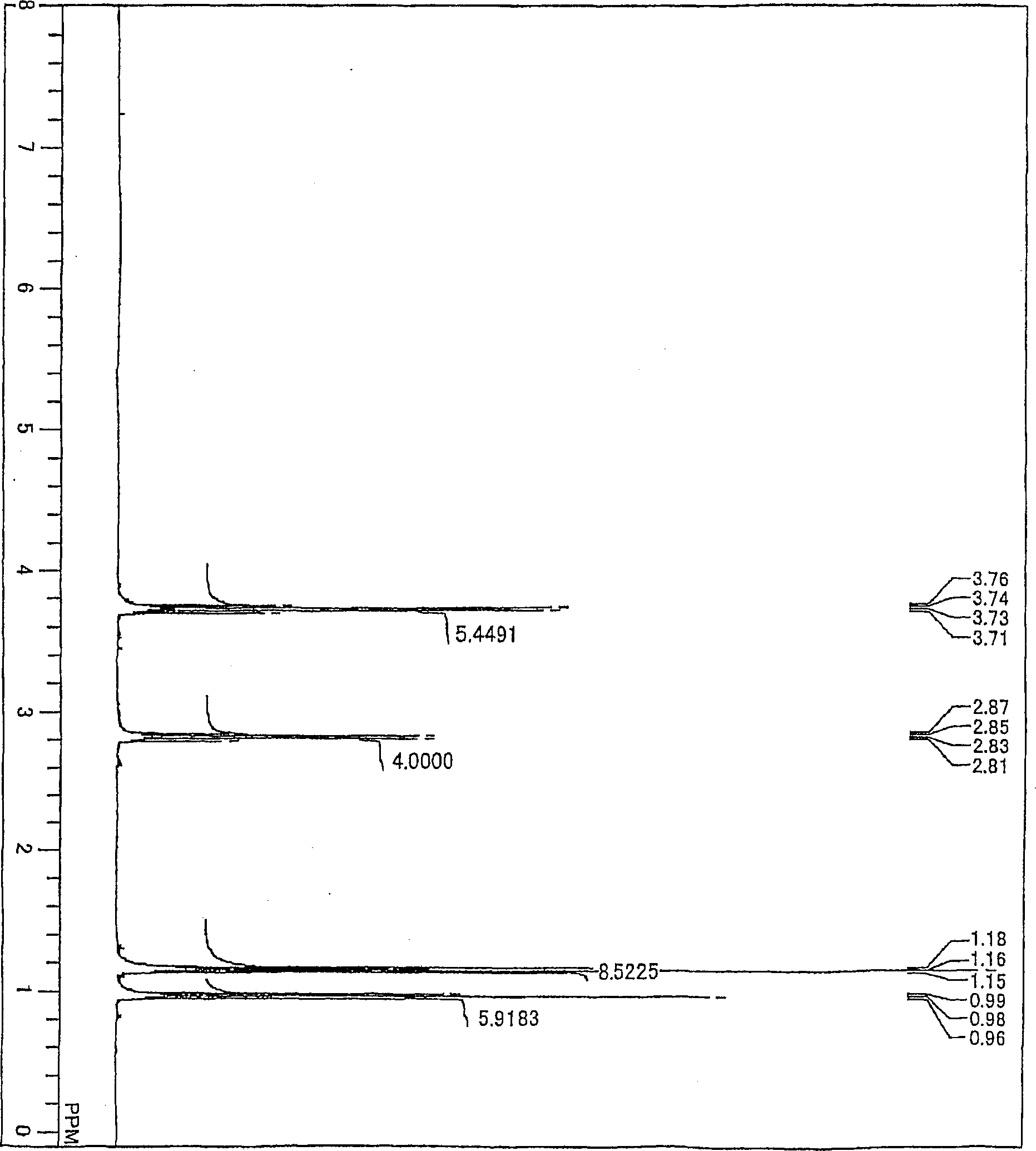

[0250] As Example 1, diethylaminotriethoxysilane was synthesized as follows. First, 100 mL of toluene, 10 mL of tetrahydrofuran, and 14.6 g (0.2 mol) of diethylamine were introduced into a four-necked flask (capacity of 1 L) equipped with a magnetically sealed stirrer and a dropping funnel, and mixed and stirred. On the other hand, 129 mL (0.22 mol) of Grignard reagent (titer=1.71 mol / L) was added to the dropping funnel. Then, while stirring, the Grignard reagent was added dropwise into the flask from the dropping funnel at room temperature (air cooling) over 30 minutes. After completion of the dropwise addition, the mixture was stirred at 60° C. for 1 hour to perform a Grignard exchange reaction. Then, 41.7 g (0.2 mol) of tetraethoxysilane previously introduced into the dropping funnel was dropped into the flask over 15 minutes. After completion of the dropwise addition, the reaction was carried out at 60° C. for 2 hours. At this point, solid ethoxymagnesium chloride preci...

Embodiment 2

[0252] As Example 2, diethylaminotri-n-propoxysilane was synthesized. In the synthesis method of Example 1, it synthesize|combined similarly except having used 52.9 g of tetra-n-propoxysilanes instead of 41.7g of tetraethoxysilanes. The appearance of the objective product was a colorless transparent liquid, the boiling point was 72.0° C. / 5 mmHg, and the GC purity was 97.5%.

Embodiment 3

[0254] As Example 3, dimethylaminotriethoxysilane was synthesized. In the synthesis method of Example 1, it synthesize|combined by the same method except having used 9.0 g of dimethylamines instead of 14.6 g of diethylamines. The appearance of the target object was a colorless transparent liquid, the boiling point was 81.0° C. / 48 mmHg, and the GC purity was 95.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com