Colored interference pigments having metallic luster, preparing method and use of same

A technology of metallic luster and interference pigments, applied in pigment preparation, pigment slurry, inorganic pigment treatment, etc., can solve problems such as undescribed interference colors, achieve high gloss coloring, high coloring, improve cohesiveness and compactness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

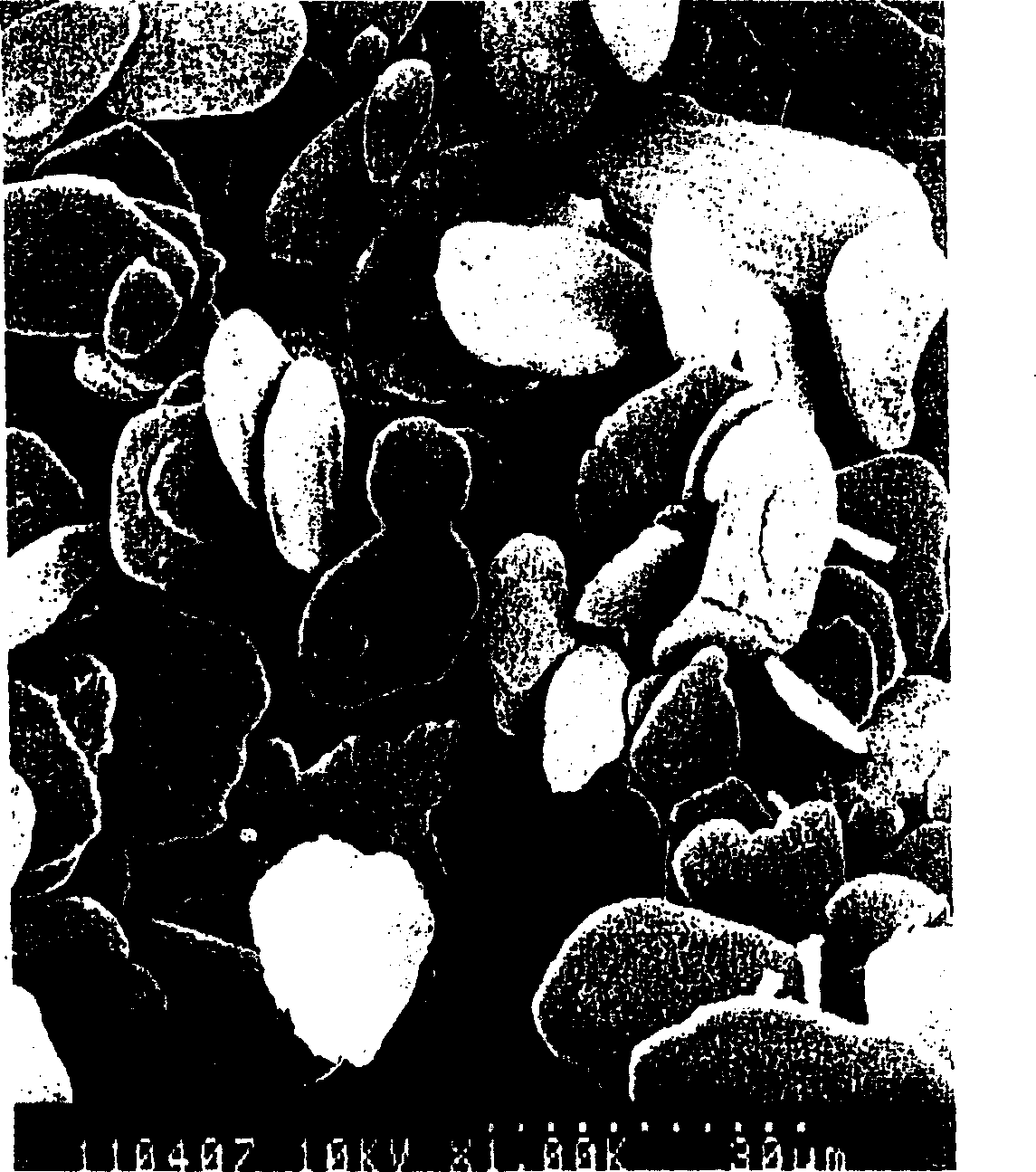

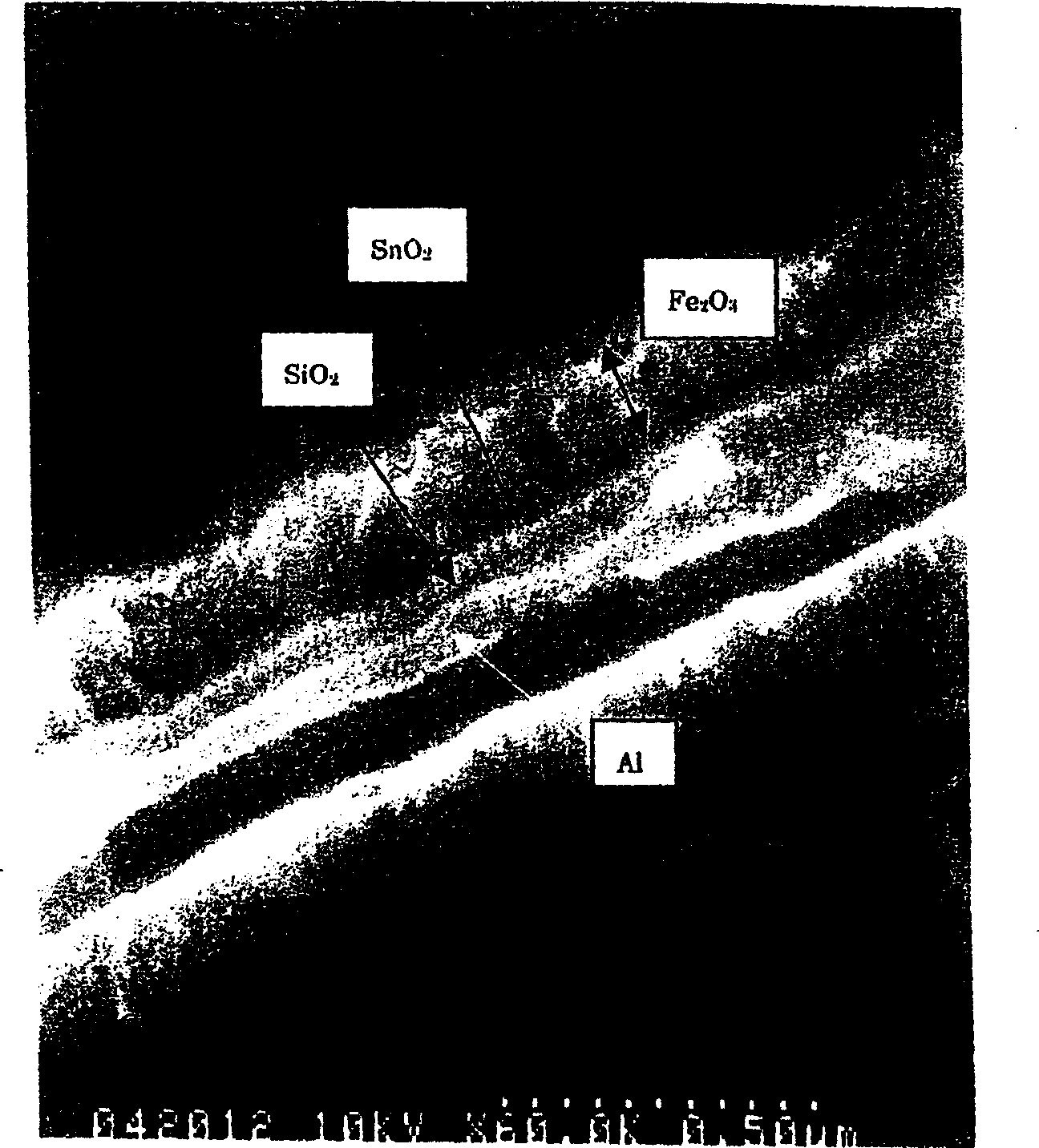

[0088] Preparation of colored interference pigments with reddish metallic luster (Fe 2 o 3 / SnO 2 / [SiO 2 / Al(P)])

[0089] 50g has the flake metal substrate ([SiO 2 / Al(P)] obtained by Example 4-b in the paragraph [0061] of JP-A-2003-41150, the specific surface area is 3.01m 2 / g) suspended in 1 liter of water. The suspension was heated to 75°C with stirring. 100 g of SnCl with a concentration of 29 g / l was added dropwise to the suspension 4 5H 2 O solution while maintaining a pH of 1.8 using 32 wt% aqueous sodium hydroxide solution (preparation of the first layer, "intermediate adhesive layer"). Then 32 wt% sodium hydroxide was used to further adjust the pH to 3.0. Then drop 1816g of FeCl with a concentration of 30g / l 3 (III) Aqueous solution until the desired color shade is achieved while maintaining a pH of 3.0 with 32% by weight of sodium hydroxide (preparation of the second layer). The solid part was filtered out from the suspension, washed, dried, and calcine...

Embodiment 2

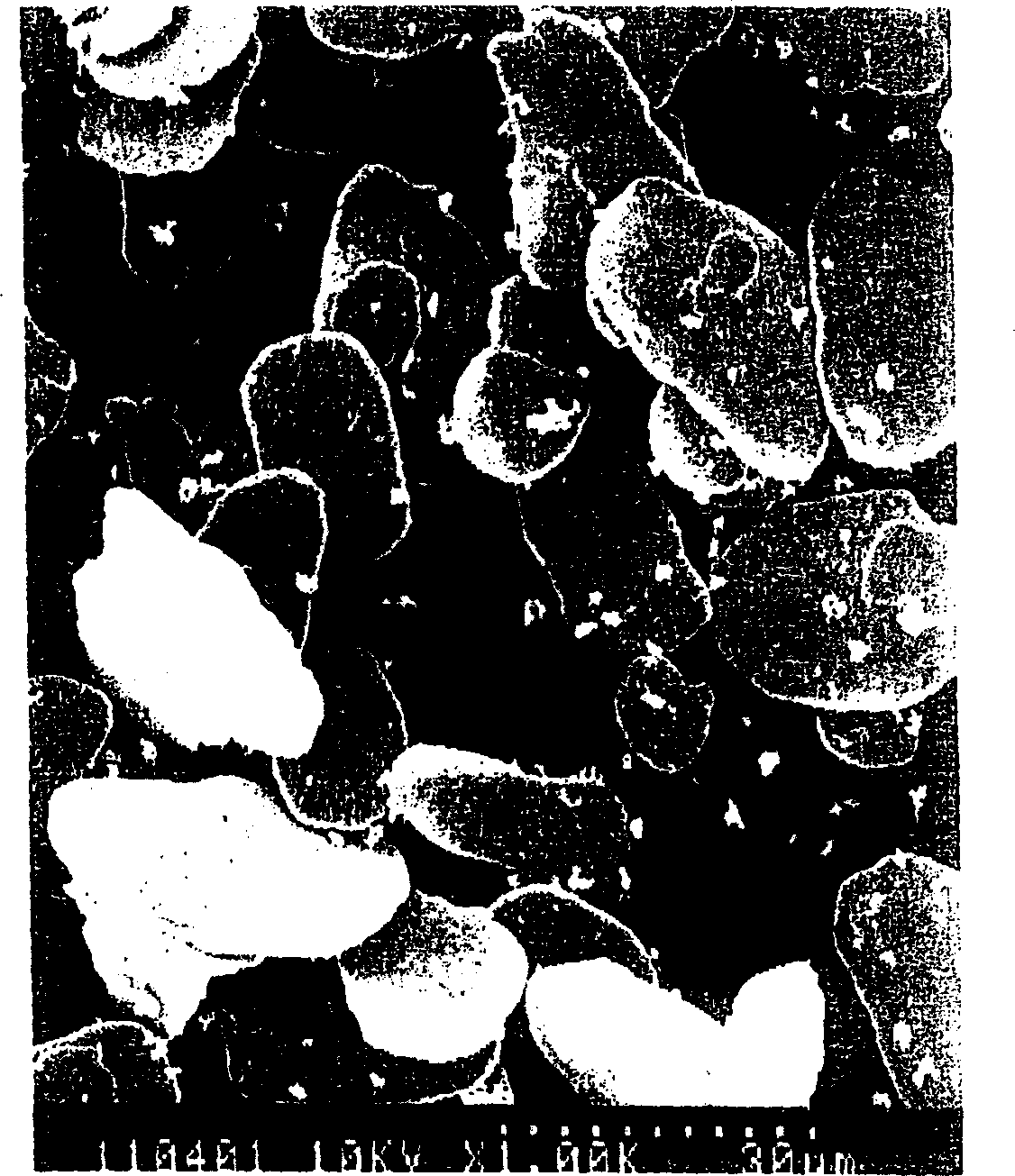

[0103] Preparation of colored interference pigments with reddish metallic luster (Fe 2 o 3 / SnO 2 / [SiO 2 / Al(P)])

[0104] 100g has the flake metal matrix ([SiO 2 / Al(P)] obtained by Example 4-b in the paragraph [0061] of JP-A-2003-41150, the specific surface area is 3.01m 2 / g) suspended in 2 liters of water. The suspension was heated to 75°C with stirring. 186ml of SnCl with a concentration of 50g / l was added dropwise to the suspension 4 5H 2 O solution while maintaining a pH of 1.8 using 20 wt% aqueous sodium carbonate (preparation of the first layer, "intermediate adhesive layer"). Then 20 wt% sodium carbonate was used to further adjust the pH to 3.0. Then drop 4540g of FeCl with a concentration of 87.75g / l 3 (III) Aqueous solution until the desired color shade is achieved while maintaining a pH of 3.0 using 20 wt% sodium carbonate (preparation of the second layer). The solid part was filtered from the suspension, washed, dried, and calcined at 350° C. for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com