Gasket raw material

A technology of gaskets and fillers, applied in the fields of gasket materials, engines and transmissions, to achieve the effect of avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

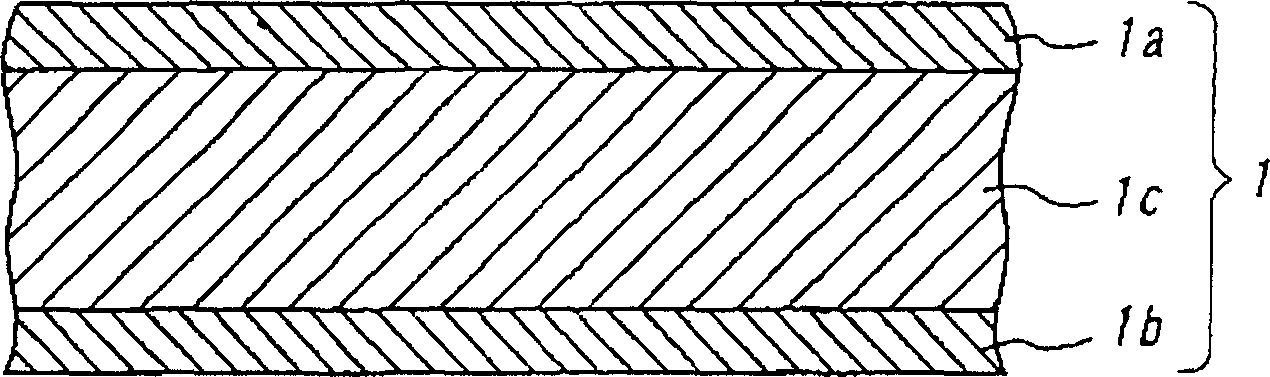

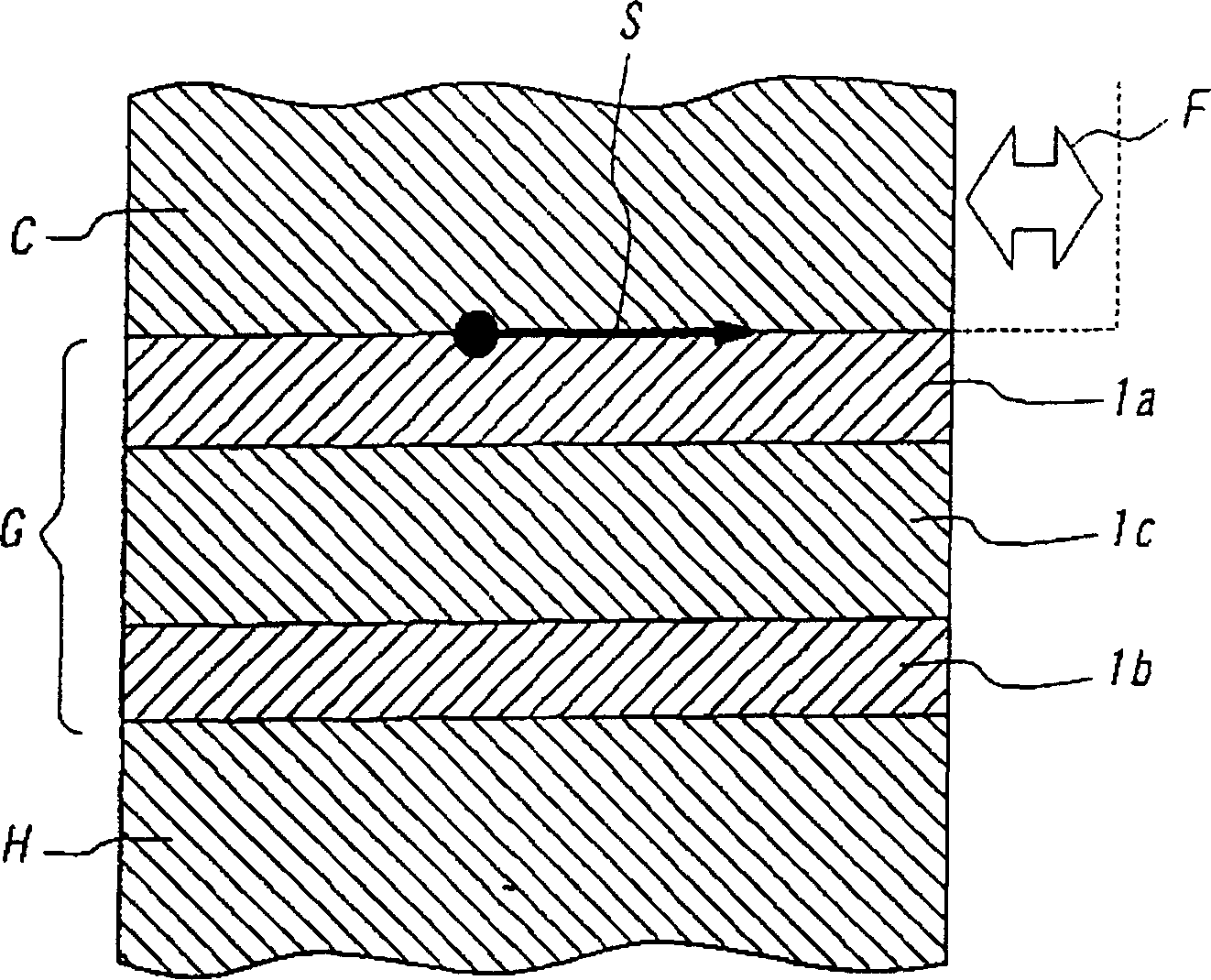

[0083] The bonding seat 1 of the first embodiment is formed by the following process. First, a one-component material is manufactured by mixing rubber (for example, nitrile butadiene rubber (NBR)), micronized reinforcing fibers (fiber bundles, for example, aramid as an organic fiber) Fiber (aramid fiber)), glass fiber (as an inorganic fiber to replace asbestos), needle-shaped inorganic fillers, and other fillers (such as barium sulfide). Then, the component material is added to a calender roll including a pair of rolls (hot and cold rolls), a calender roll, and a calender roll by mixing and squeezing the rolls to The ingredients that form a sheet are on a hot rolling wheel. The composition is then vulcanized and thermally hardened and cured by using the heat of a hot roller to form a joint seat. Then, the joint seat is formed by separating from the hot rolling wheel. like figure 1 As shown, in this process, the above-mentioned three-layer front surface layer 1a, rear surf...

experiment example 1

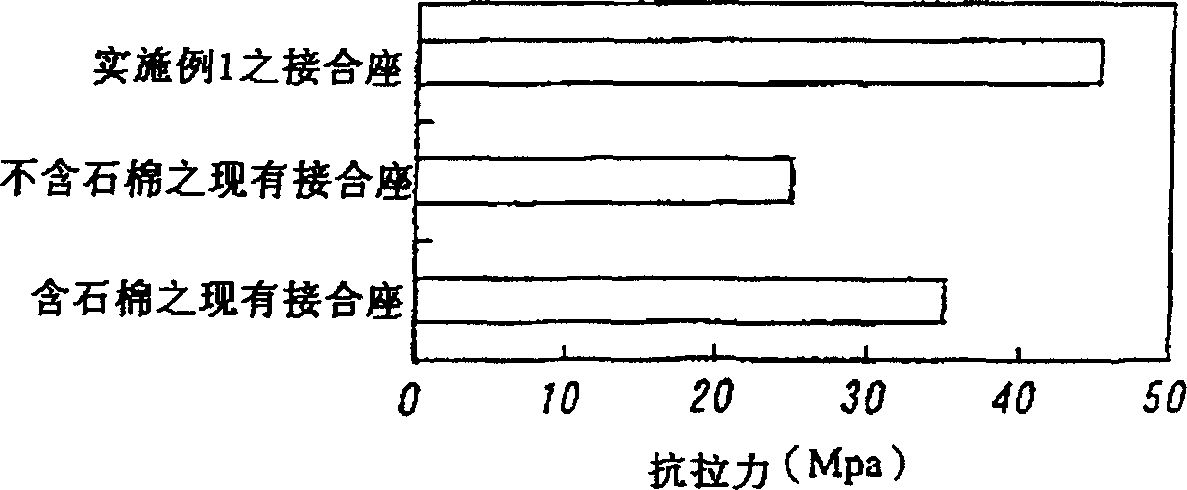

[0089] Table 1 below lists the test results of the tensile strength of the splice sockets, wherein samples 1-1 to 1-3 are splice sockets 1 with the same thickness of 0.5 mm and different mixing compositions. The comparative samples 1-1 and 1-2 are similar to the splice base 1 with the same thickness of 0.5 mm, and the composition of each needle-like fiber is 0 wt % and 50 wt %, respectively. These samples were fabricated and tested for tensile strength by a tensile test under the test conditions defined in JIS K 6251. As shown in the results in the table, the tensile strength of both comparative samples 1-1 and 1-2 is lower than 40 MPa. On the other hand, all of the samples 1-1 to 1-3 have a tensile force exceeding 45 MPa, which shows that these samples are gasket materials with a relatively high tensile force.

[0090] Group of Experimental Cases

to make

Composition (wt%)

tensile strength

(MPa)

Aramid fiber

dimension

rubber

...

Embodiment 2

[0094] The bonding base 1 of the second embodiment is formed by the following process. First, a one-component material is manufactured by mixing rubber (such as nitrile rubber (NBR)), reinforcing fibers (fibers used to replace asbestos, such as aramid fibers or glass fibers), and fillers ( For example, barium sulfide) and so on. Then, the component material is fed to a calender roll including a pair of rolls (hot roll and cold roll) to a hot roll by mixing and pressing the rolls to form a thin sheet Ingredients are on hot rolling wheels. The composition is then vulcanized and thermally hardened and cured by using the heat of a hot roller to form a joint seat. Then, the joint seat is formed by separating from the hot rolling wheel. In this process, the above-mentioned three-layer front surface layer 1a, rear surface layer 1b, and intermediate layer 1c of the above-mentioned bonding seat 1 are mainly formed by changing the composition of reinforcing fibers (for more details a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com