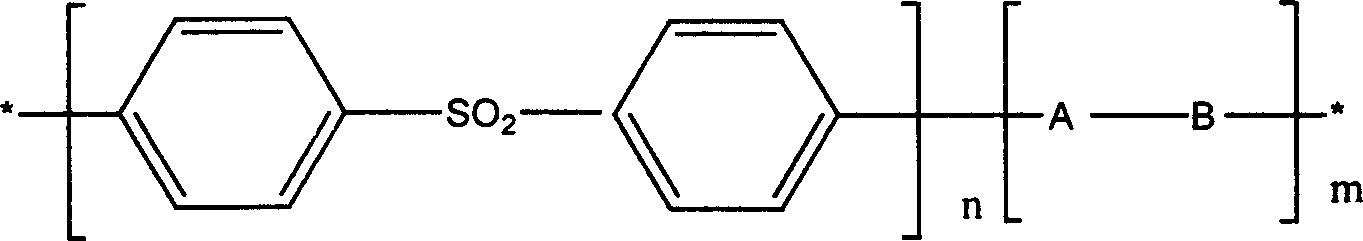

Redispersible polyarylethersulphones micropowder and method for preparing same

A polyarylene ether sulfone and redispersibility technology is applied in the field of preparation of redispersible polyarylene ether sulfone micropowders, and can solve the problems of low content of polyarylene ether sulfone, not completely water-based, and unfavorable environmental protection. , to achieve the effect of expanding the scope of application, avoiding pollution, and being conducive to preservation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of redispersible polyethersulfone micropowder

[0035] Thoroughly mix 240ml of chloroform with 30ml of methanol, dissolve 4g of polyvinylpyrrolidone (PVP) in the above solution, and dissolve 140g of polyethersulfone in the above mixed solution to prepare a polyethersulfone solution.

[0036] Dissolve 8g of sodium dodecylbenzenesulfonate in 280ml of deionized water; pour the aqueous solution of sodium dodecylbenzenesulfonate into the colloid mill, then slowly add the polyethersulfone solution into the colloid mill to disperse.

[0037] Pour the prepared polyethersulfone emulsion containing organic solvent into a 1000 ml three-necked flask equipped with a stirring device and a condensing device, and heat it in a water bath. The temperature control range is 55°C for 3 hours, and 65°C for 3 hours until no solvent evaporates. Until then, heat up to 85°C for 30 minutes. Stop stirring and stop heating to obtain a water-based water-based polyarylethersulf...

Embodiment 2

[0039] Example 2 Preparation of redispersible polyethersulfone micropowder

[0040] Thoroughly mix 240ml of chloroform and 20ml of methanol, and dissolve 90g of polyethersulfone in the above mixed solution.

[0041] Dissolve 8 g of sodium dodecylbenzenesulfonate in 280 ml of deionized water. Pour the sodium dodecylbenzenesulfonate aqueous solution into the colloid mill, then slowly add the polyethersulfone solution into the colloid mill for dispersion.

[0042] Pour the prepared polyethersulfone emulsion containing organic solvent into a 1000 ml three-necked flask equipped with a stirring device and a condensing device, heat it in a water bath, and control the temperature at 55°C for 3 hours and 65°C for 3 hours until no solvent evaporates , and then heated to 85 ° C for 30 minutes. Stop stirring and stop heating to obtain a water-based water-based polyarylethersulfone dispersion.

[0043] The spray drying process parameters are: inlet temperature 112°C, outlet temperature ...

Embodiment 3

[0044] Example 3 Preparation of redispersible polyethersulfone micropowder

[0045] Thoroughly mix 240ml of chloroform and 10ml of methanol, and dissolve 90g of polyethersulfone in the above mixed solution.

[0046] Dissolve 6 g of sodium dodecylbenzenesulfonate in 280 ml of deionized water. Pour the sodium dodecylbenzenesulfonate aqueous solution into the colloid mill, then slowly add the polyethersulfone solution into the colloid mill for dispersion.

[0047] Pour the prepared polyethersulfone emulsion containing an organic solvent into a 1000 ml three-neck flask equipped with a stirring device and a condensing device, and heat it in a water bath. The temperature control range is 55°C for 2 hours, and 65°C for 3 hours until no solvent evaporates. Then, the temperature was raised to 80°C for 30 minutes. Stop stirring and stop heating to obtain a water-based water-based polyarylethersulfone dispersion.

[0048] The spray drying process parameters are: inlet temperature 112°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com