Probe unit of microscope with atomic force and manufacturing method

A technology of atomic force microscope and manufacturing method, which is applied in measurement device, scanning probe technology, scanning probe microscopy and other directions, can solve the problem of low orientation of carbon nanotubes, achieve uniform hole diameter, easy control of depth, and improve the precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

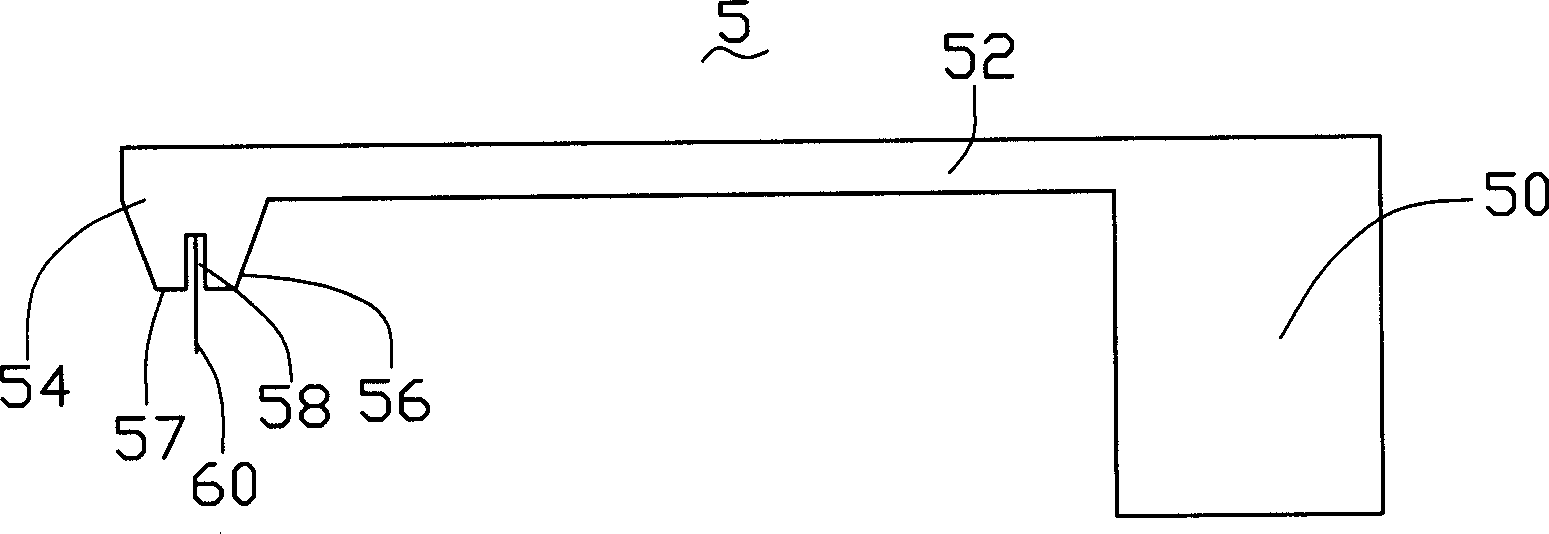

[0019] see figure 1 , the AFM probe device 5 provided by the present invention includes: a probe base 50; a cantilever 52 fixed on the probe base 50, having an end 54; a carbon nanotube used as a needle tip at the end 54 of the cantilever 60. Wherein, the top 56 of the cantilever end 54 forms a plane 57 , and the plane 57 has a hole 58 . Carbon nanotubes 60 grow out of the hole 58 and are substantially perpendicular to the plane 57 .

[0020] In this embodiment, the diameter of the hole 58 is preferably 20-100 nanometers. Cantilever 52 may be made of silicon nitride.

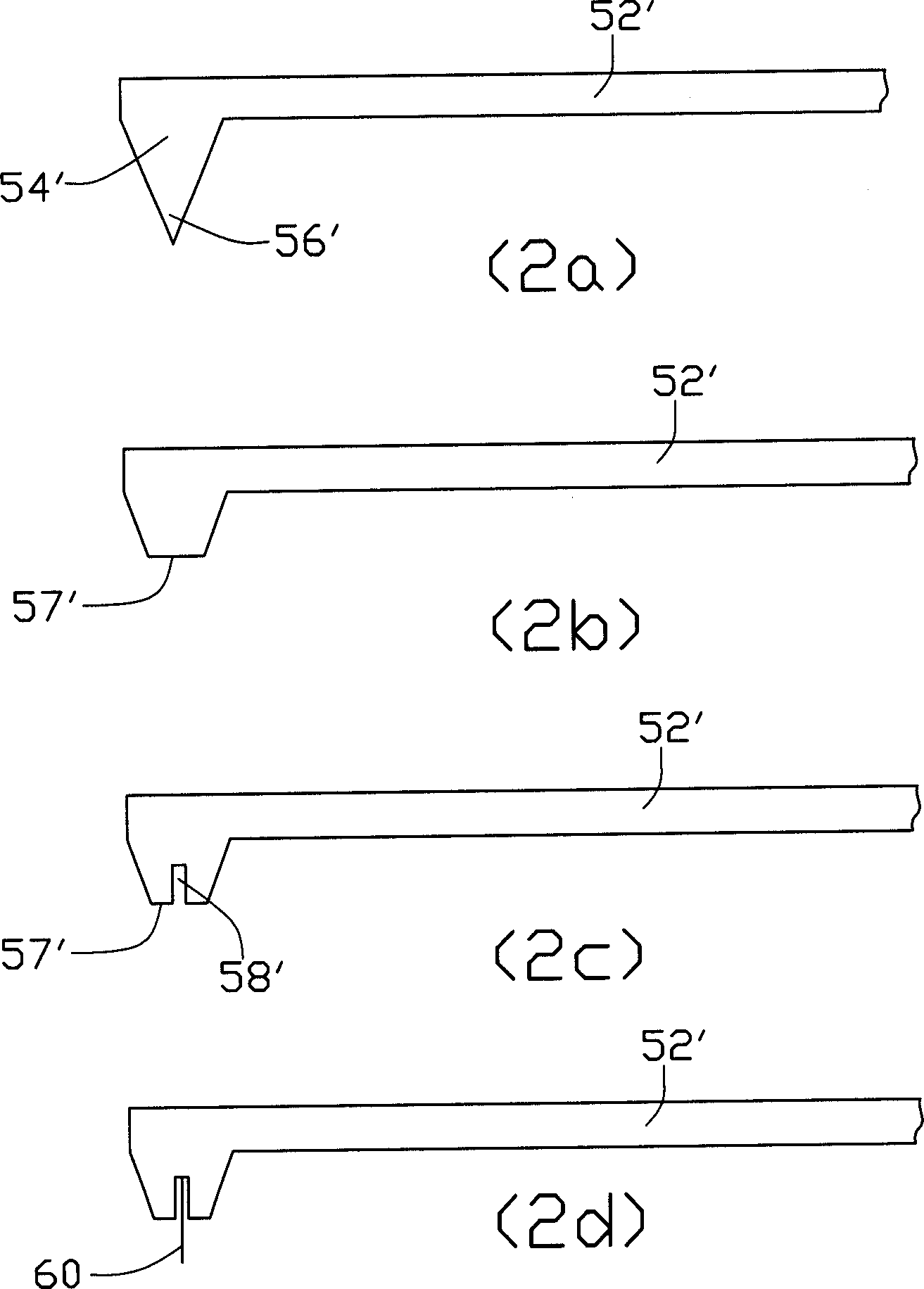

[0021] see figure 2 , the manufacturing method 7 of the above-mentioned AFM probe device 5 provided by the present invention comprises steps:

[0022] (2a) providing an AFM-usable cantilever 52' having a tipped end 54' having a pointed top 56';

[0023] (2b) A plane 57' can be formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com