Crankshaft production machine

A technology of crankshaft processing and crankshaft, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems such as the decrease of the stability of the milling unit itself, the unimaginable high precision processing of the workpiece, and the limited surface quality of the workpiece. Achieve high stability, eliminate gaps, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

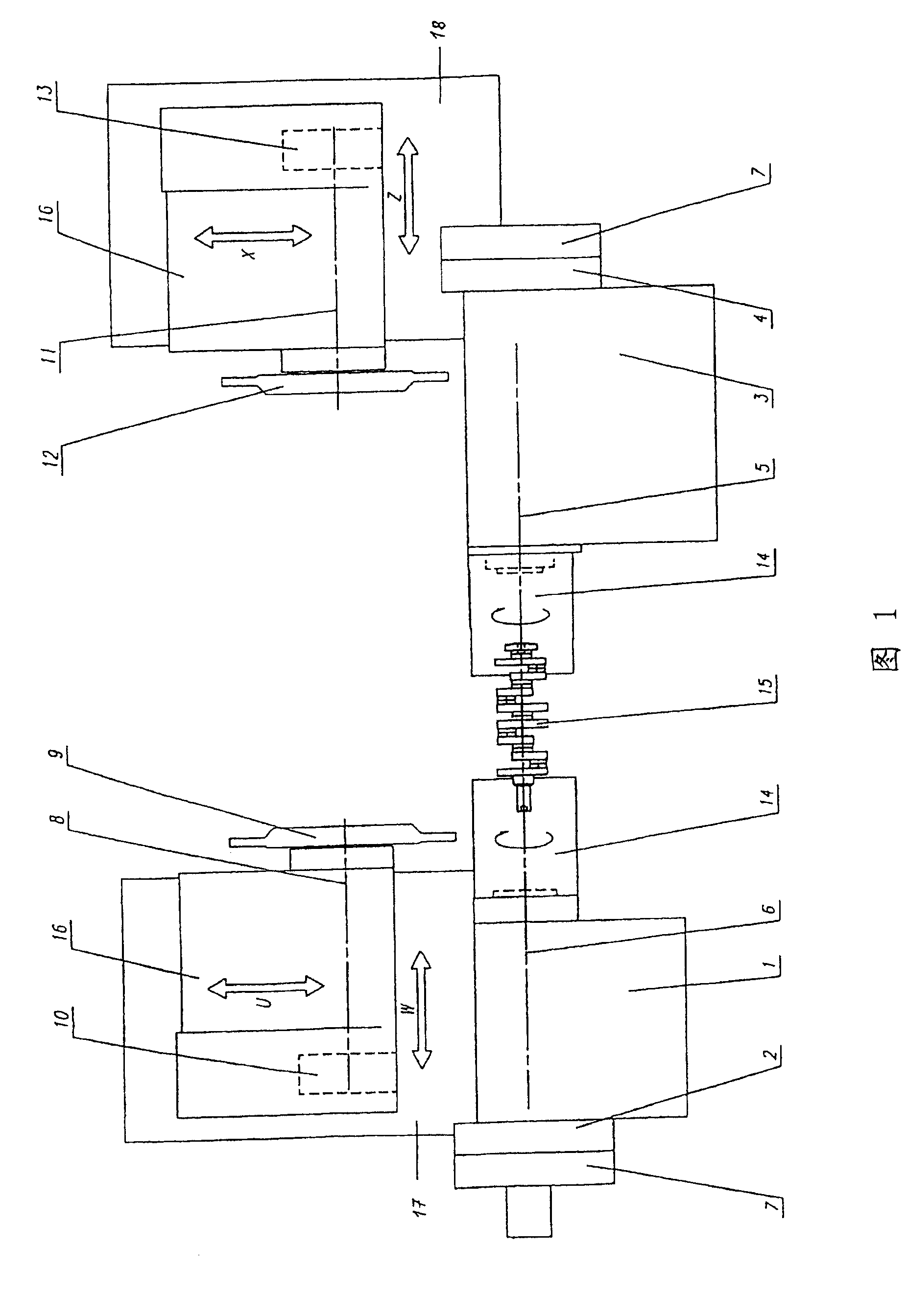

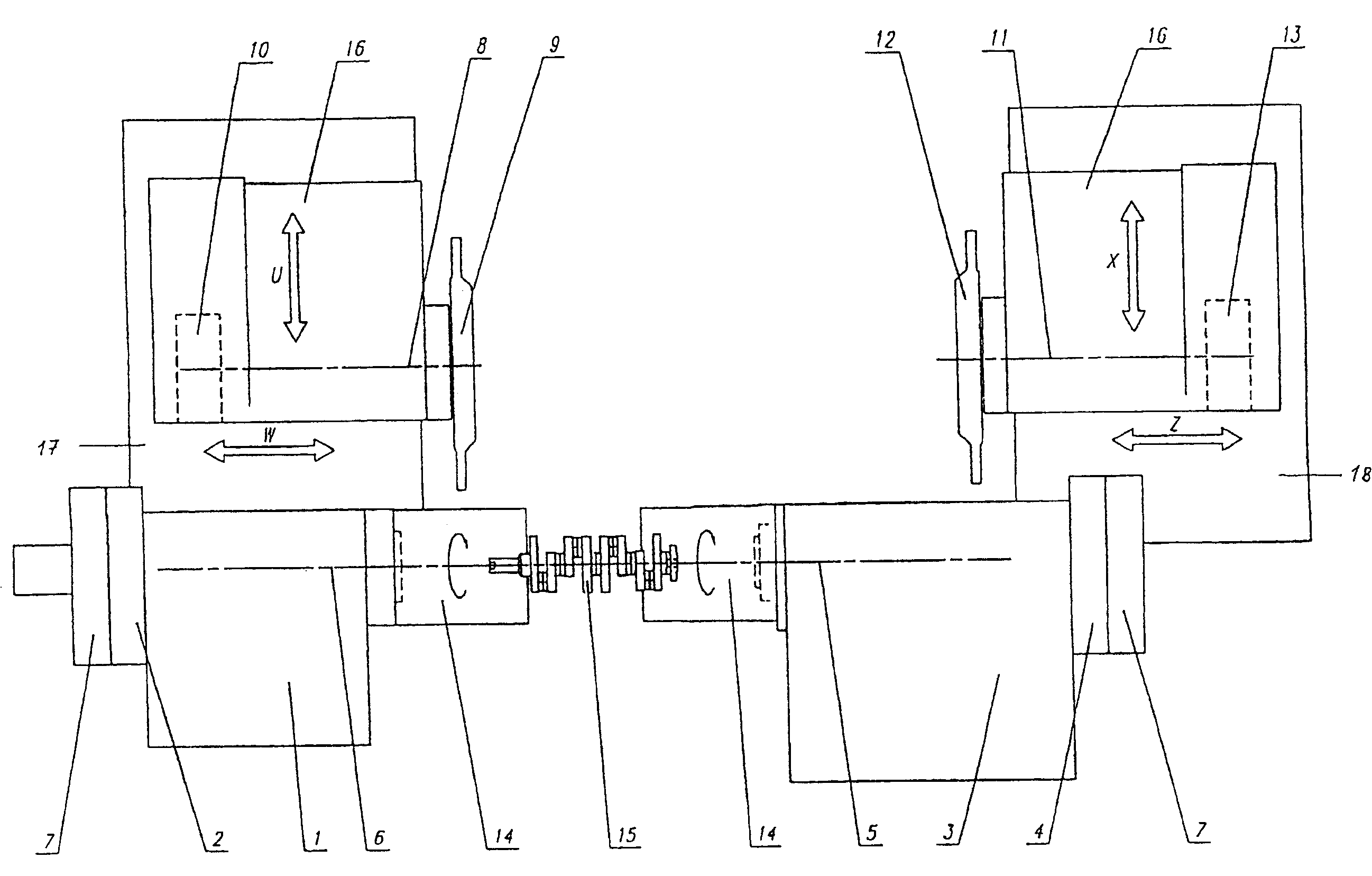

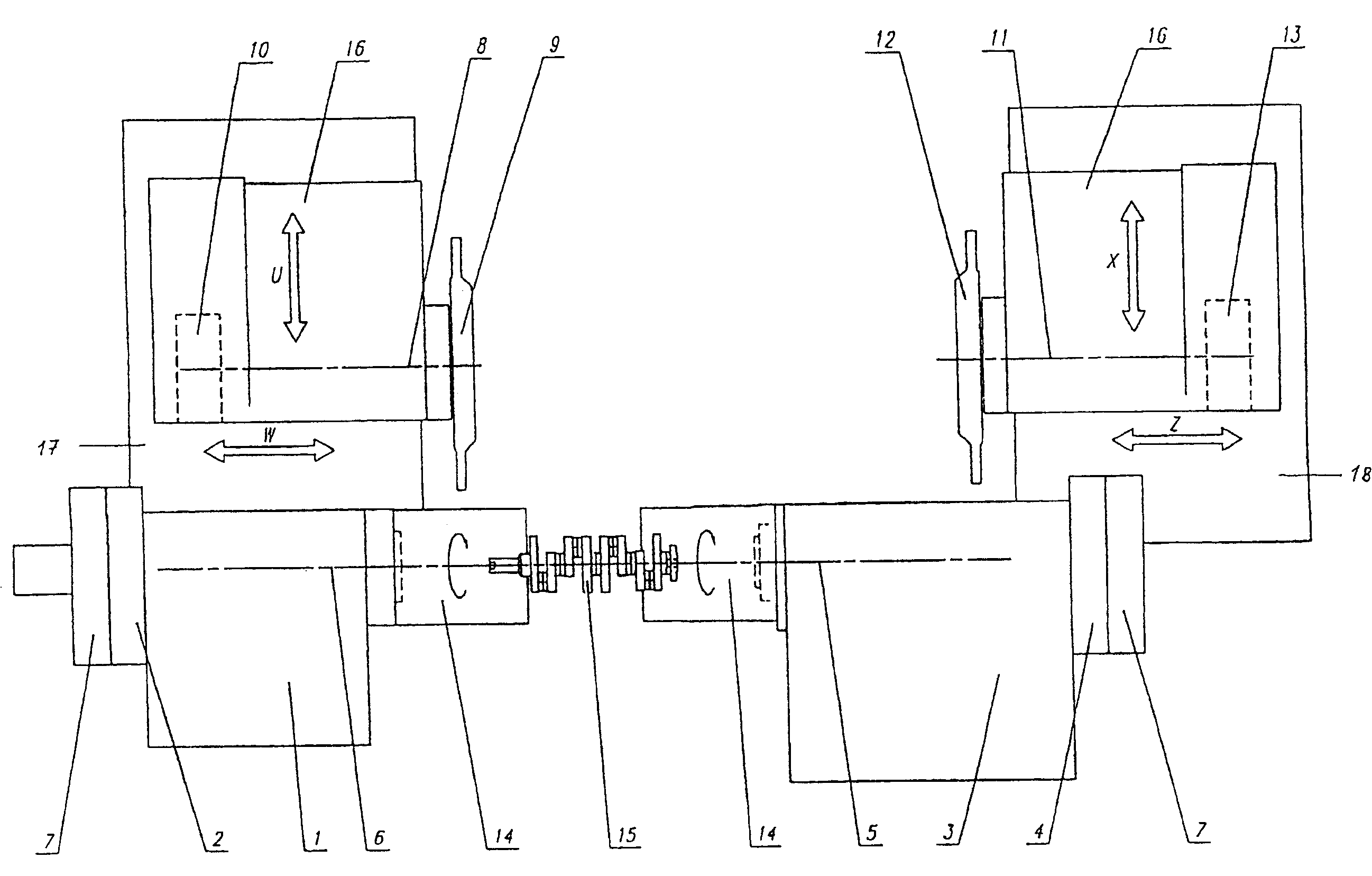

[0020] figure 1 shows a crankshaft machining machine with a headstock. The headstock has a first workpiece spindle 1 which is rotatable about a C-axis 6 . Corresponding to the spindle box, there is also a torque motor 2 as a spindle drive device. The axis of the motor 2 coincides with the gripper axis 6 . A measuring system 7 is an integral component of the positionally adjustable spindle drive. In contrast, a torque motor 4 with an integrated C-axis 5 is provided as drive on a counter spindle with a second workpiece spindle 3 . The control of the crankshaft processing machine allows electronic synchronization of the above-mentioned two workpiece spindle drives.

[0021] The workpiece 15 to be machined in the form of a crankshaft is clamped by means of the clamping device 14 .

[0022] The crankshaft machining machine includes two milling units. On the two longitudinal slides or slides 17 and 18 displaceable in the Z and W directions of the two milling units there is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com