Hybrid integrated tunable semiconductor laser

A hybrid integration and laser technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of increasing the difficulty of device manufacturing and slow tuning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

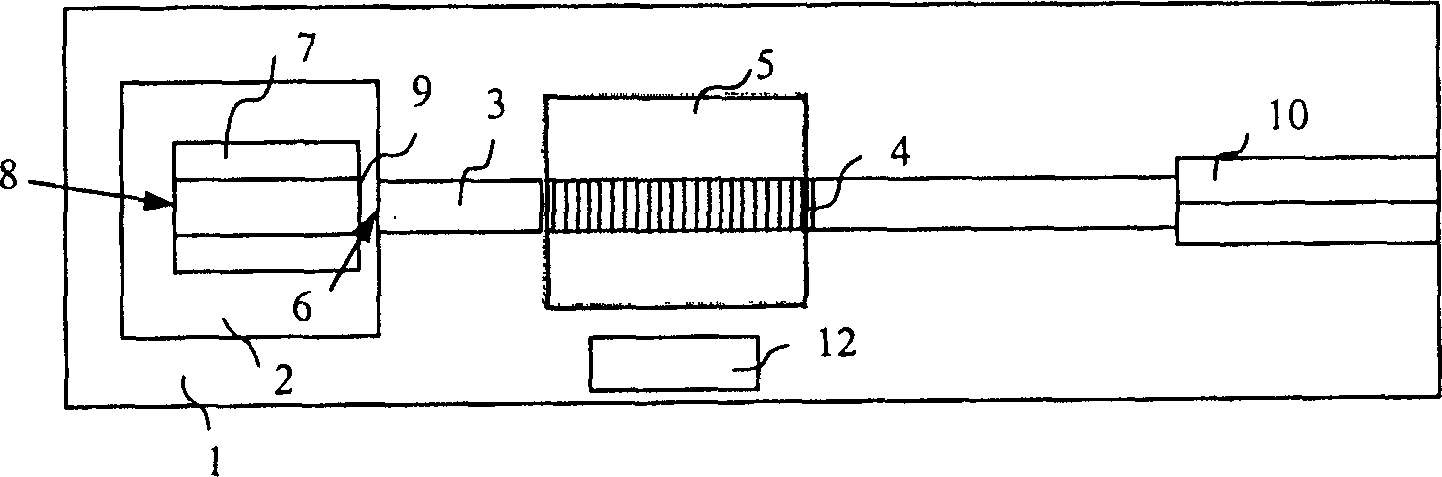

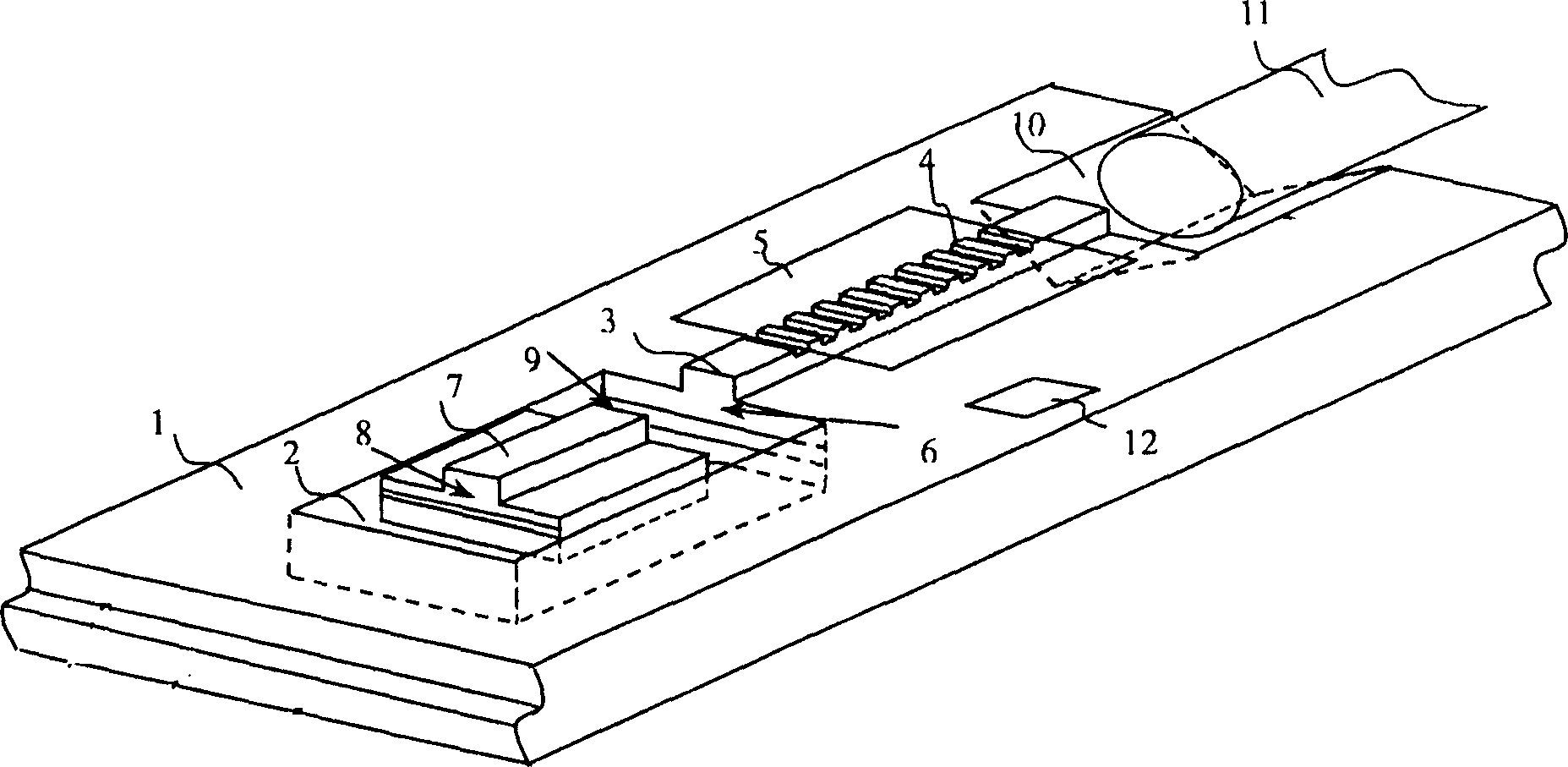

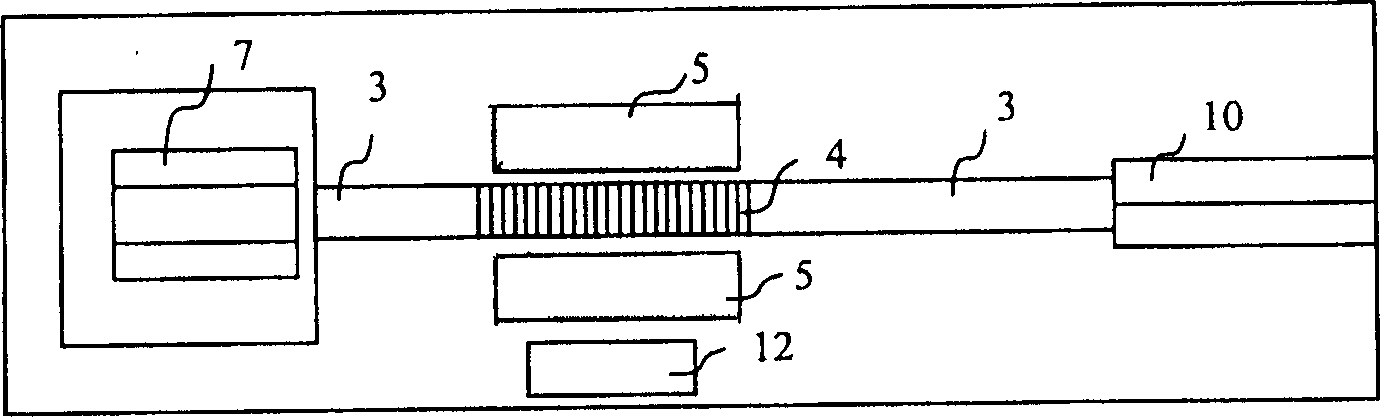

[0021] See Figure 1 and figure 2 , Figure 1 and figure 2 They are schematic diagrams and perspective views of the thermo-optic tunable laser according to the first embodiment of the invention, and the substrate 1 includes N - Silicon light guide layer, silicon dioxide (SiO 2 ) insulating layer and silicon substrate.

[0022] The positioning groove 2 is etched on the substrate 1, preferably the positioning groove 2 is etched to the middle buried layer SiO 2 Next, this allows the use of low silicon substrates as heat sinks for lasers. A ridge waveguide 3 is carved on a substrate 1 and a grating 4 is formed on the waveguide 3 . In order to facilitate the connection with the optical fiber, a V-shaped groove 10 is formed at the end of the waveguide 3 . For the description of the structure of the external cavity laser, refer to the patent WO00 / 03461. For the details of the docking installation of the laser chip 7 and the waveguide 2, refer to the patent WO97 / 43676 cited in WO0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com