Aluminium-plastic composite section bar with inflation structure and its producing method

A composite profile and inflatable structure technology, applied in building components, building structure, window glass installation, etc., can solve problems such as unsatisfactory energy saving effect, reduced performance of aluminum-plastic windows, cracks in plastic and aluminum profiles, etc. The thermal insulation function has a clear division of labor, avoids aging, and has a small thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

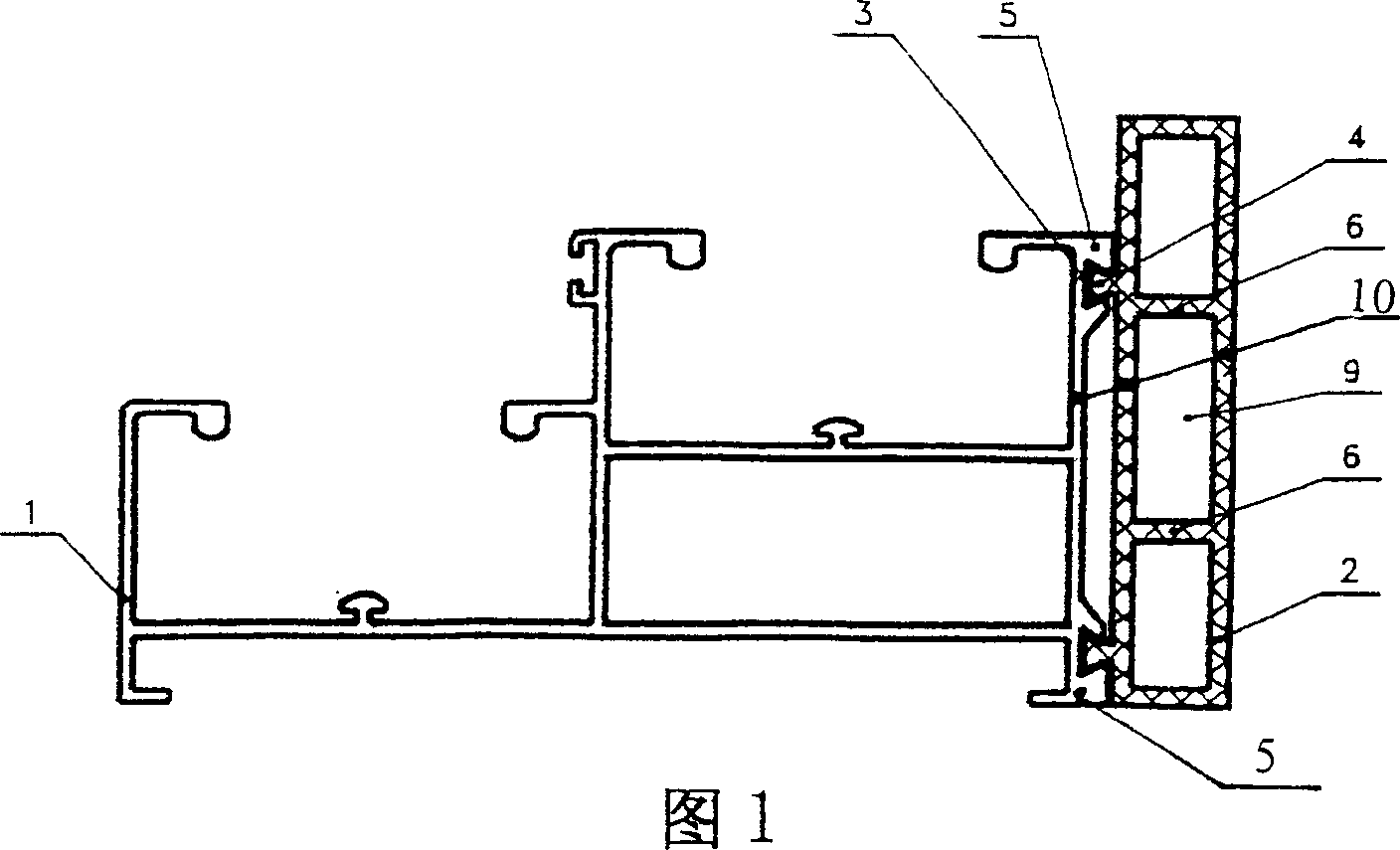

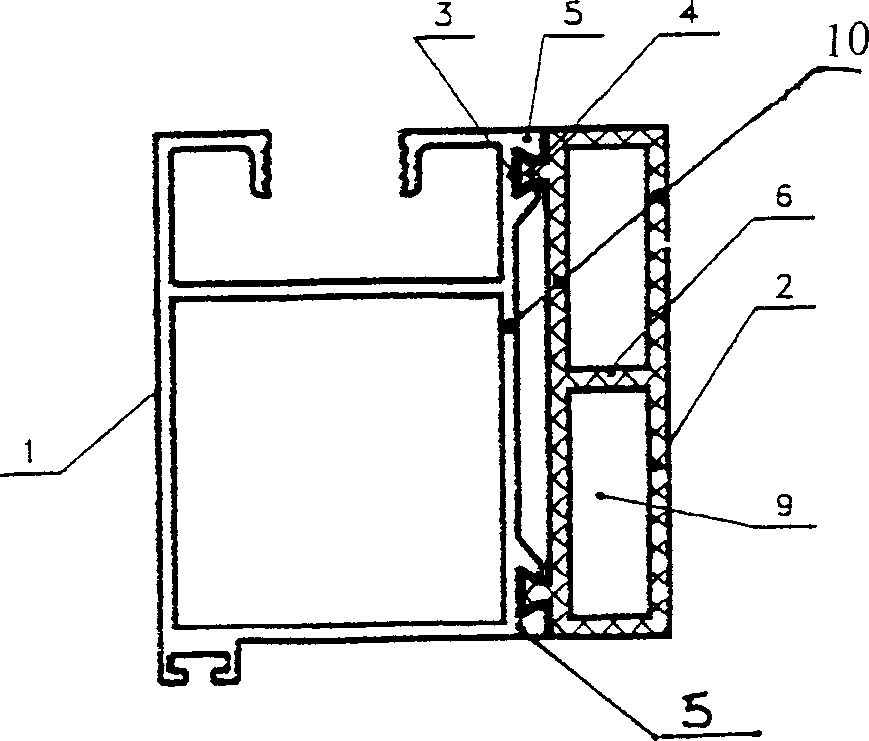

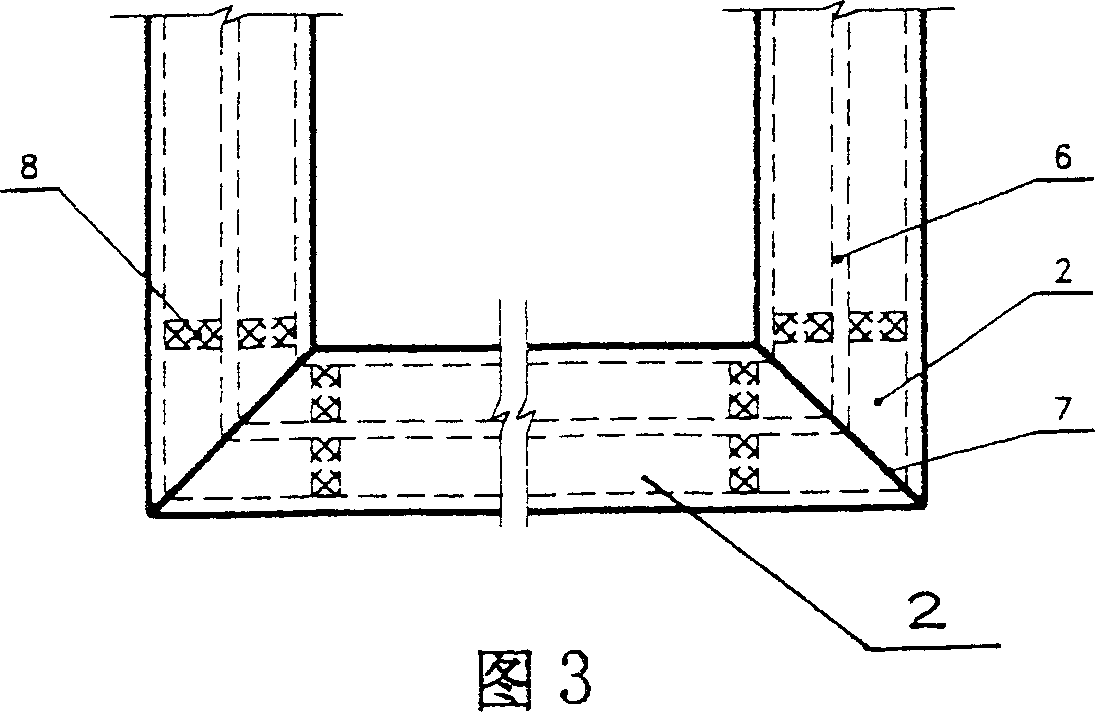

[0019] The product of the present invention is mainly composed of an aluminum alloy door and window profile 1 and a plastic inflatable profile 2 . The shape of aluminum alloy door and window profiles 1 can be determined according to the sections of various building door and window profiles. The shape of the plastic inflatable profile 2 can be determined according to the shape of the aluminum alloy door and window profile 1 and the interior decoration design requirements. The composite structure of the two profiles is as follows:

[0020] On one side of aluminum alloy door and window profile 1, at least one groove 3 is arranged along the length of the section shape, and on the side of plastic profile 2, protrusions 4 corresponding to the number and shape of the groove 3 on the aluminum alloy profile 1 are arranged along the length of the section shape. (See Figure 1, figure 2 ).

[0021] The two are pressed into a new-style inflatable structure aluminum-plastic composite pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com