Anti- biotic and mould proof resin molded body and air conditioner

A technology of resin molding and mildew resistance, which can be used in air conditioning systems, condensate prevention, plant growth regulators, etc., can solve problems such as adverse effects of resin molding, and achieve high molding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

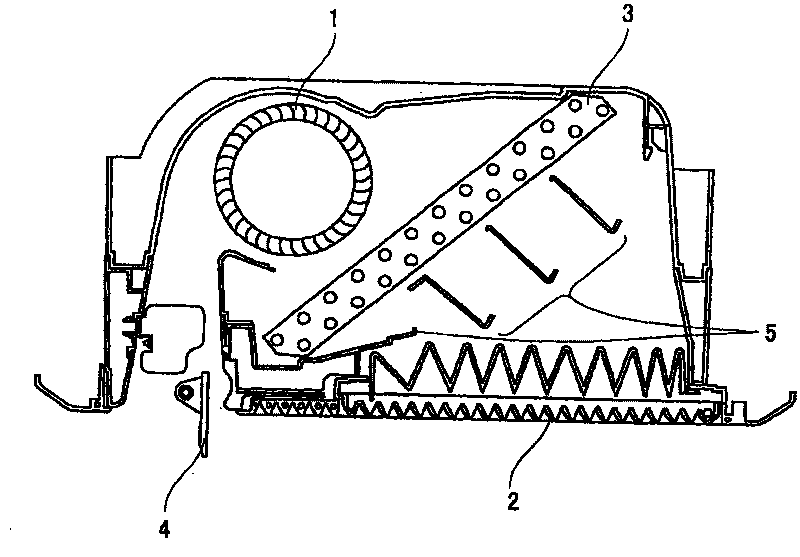

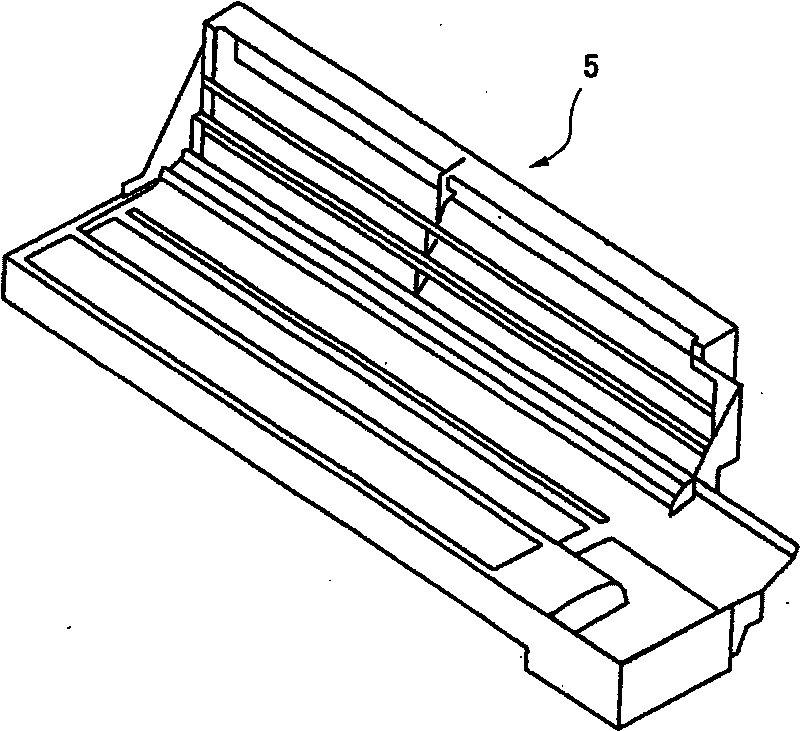

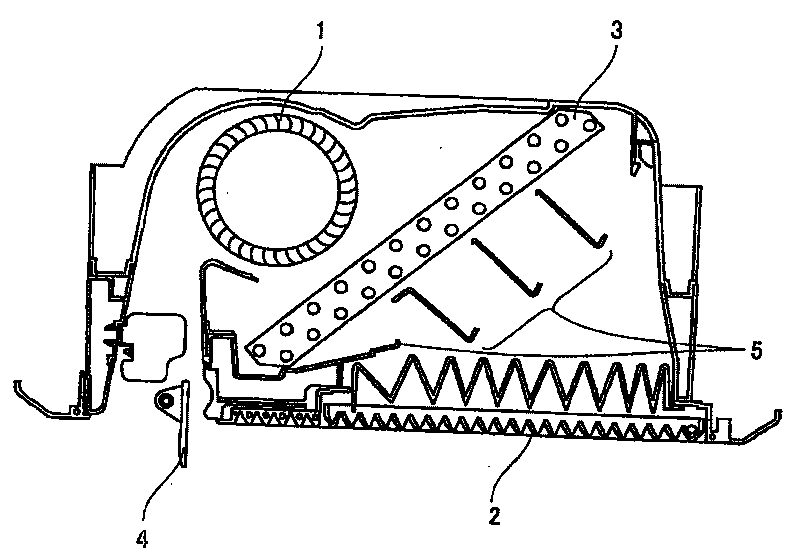

[0028] Example: Manufacture of an air conditioner drain pan dispersed with an antibacterial and antifungal agent

[0029] 80% by weight of zinc pyrithione, 18% by weight of polyolefin wax, and 2% by weight of synthetic resin lubricant were uniformly mixed at 70°C to prepare a mixture, and the mixture was mixed with polypropylene at a ratio of 1:1 at room temperature. Manufactured by injection molding figure 1 and figure 2 The dispersion amount of zinc pyrithione in the shape shown is a drainage dish of 40% by weight. The hardness (ASTM D 2240) of this drain pan is 70 to 72 (actual measurement value obtained by using a hardness meter D type manufactured by Polymer Meter Instruments Co., Ltd.), which is in a moderate hardness range (55 to 85) for elution of zinc pyrithione ( The hardness of the polypropylene molded body in which zinc pyrithione is not dispersed is 74-75).

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com