Exhaust gas purifying device

An exhaust gas purification device and ionization technology, applied in the direction of oil supply device, charging system, combustion air/combustion-air treatment, etc., can solve the problems of complex manufacturing process, increased manufacturing cost, poor formability, etc. The effect of uniformity and shape, control of manufacturing costs, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

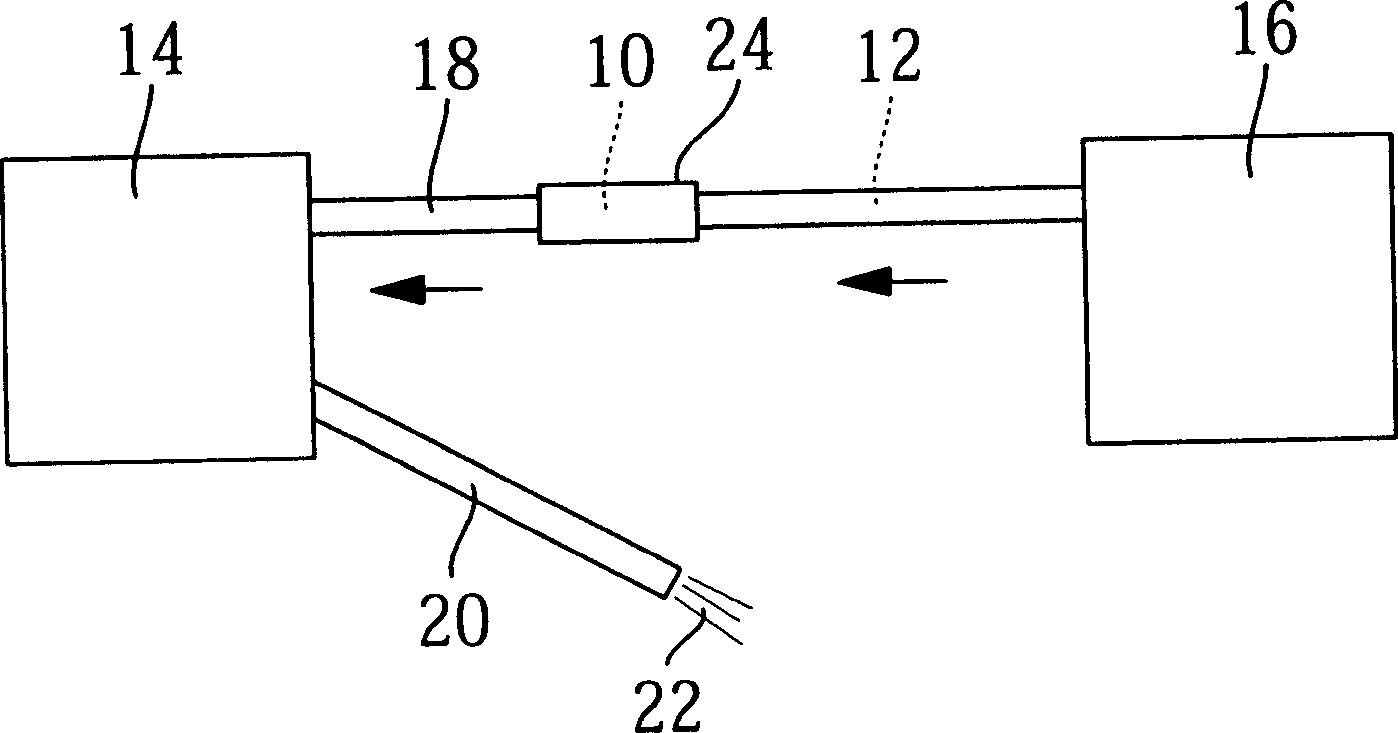

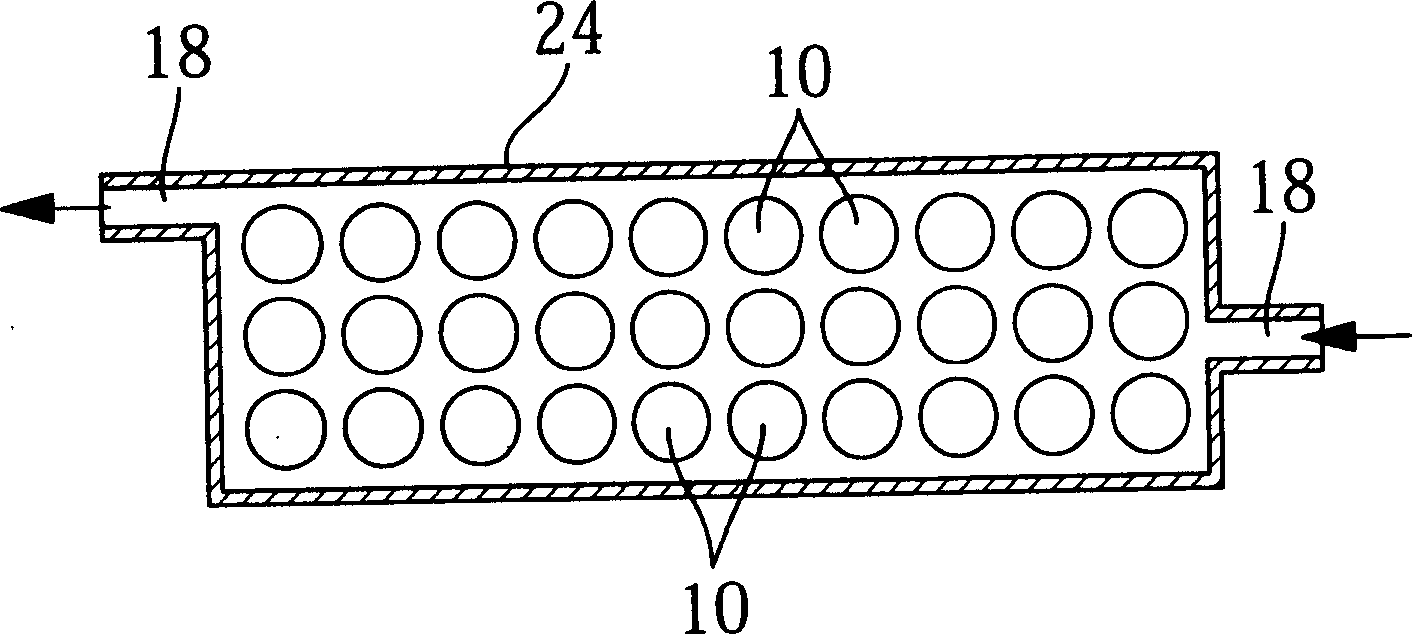

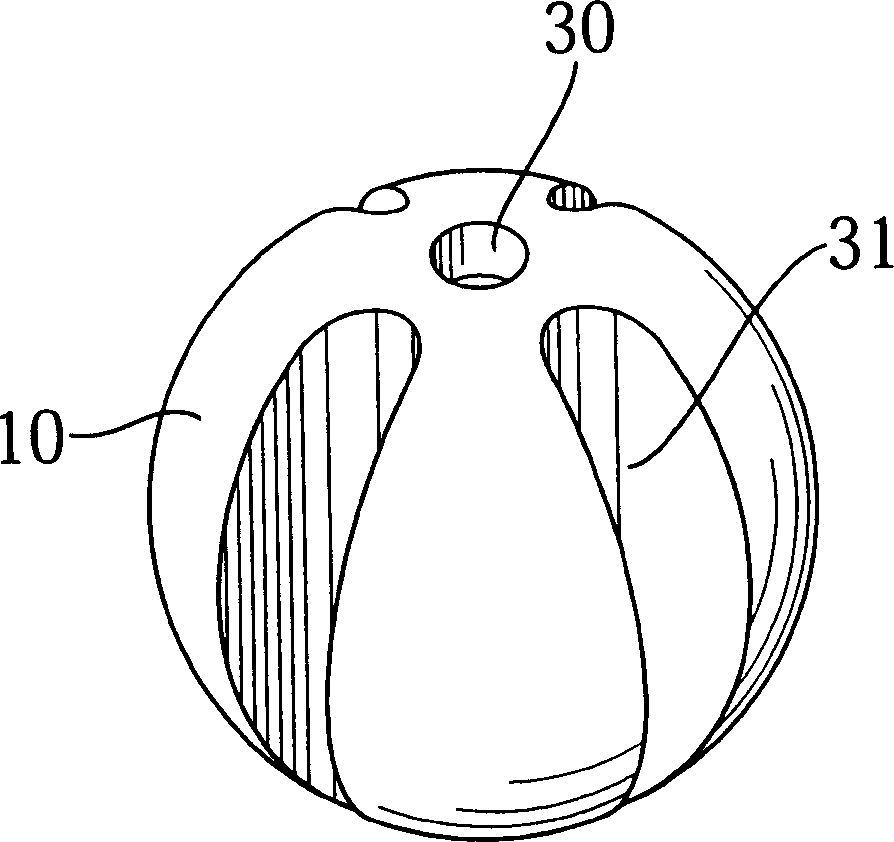

[0030] Connect the following two fuel ionization exhaust gas purification devices to the same automobile fuel pipeline of a gasoline engine 1800cc to study the concentration of CO and HC in the exhaust gas 22. and the sphere (diameter 8mm) obtained by mixing the 2~5 μm powder of nylon and pottery with a weight ratio of 90:10 is placed in the cylindrical body 24 (diameter 30mm, length 95mm), an exhaust gas purification device that causes fuel ionization by a mixture of nylon and ceramics. The results are shown in the table below.

[0031] Gasoline engine 1800cc

[0032] The instrument used for the above measurement is a CO-HC analyzer EIR2105 (Yanagawa Co., Ltd.), which is used to measure the exhaust gas at no-load. From the results of this experiment, it can be seen that the exhaust gas purification device in which fuel is ionized by a mixture of nylon and ceramics is very stable and effective in reducing harmful substances contained in exhaust gas.

Embodiment 2

[0034] Carry out the same experiment with embodiment 1 on the automobile of gasoline engine 3000cc. The results are shown in the table below.

[0035] Gasoline engine 3000cc

CO(%)

HC (ppm)

usually

0.38

111

Installed with device (nylon)

0.06

13

Set with fittings (nylon and ceramic)

0.01

6

[0036] From the results of this experiment, it can be judged that the exhaust gas purification device in which the fuel is ionized by the mixture of nylon and ceramics can more stably and effectively reduce harmful substances contained in the exhaust gas.

[0037] In this way, it can be judged that the harmful substances contained in the exhaust gas can be stably and effectively reduced especially in a large car with an engine of 1800cc or 3000cc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com