Novolak resin mixtures and photosensitive compositions comprising the same

A technology of novolak resin and resin mixture, applied in the directions of diazo compound components, optics, optomechanical equipment, etc., can solve problems such as differential thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1 Based on (5:4:2) molar ratio m-cresol / p-cresol / trimethylphenol with the use of AZ MIF-300 developer (0.261 N tetramethylammonium hydroxide (TMAH), all obtained from AZElectronic Materials, Clariant company) is a novolak resin (unfractionated) of 113 Å / sec; also available Another resin "HPN527" from Clariant instead of "MPT 542" based on p-cresol;

[0071] 2 m-cresol based; novolak resin from AZ Electronic Materials, Clariant Company;

[0072] 3 O-quinonediazide sulfonyl diesters of polyols represented by structure (VIII) in the specification; available from AZ Electronic Materials, Clariant Company;

[0073] 4 Oxyctanoic acid (leveling agent); available from 3M.

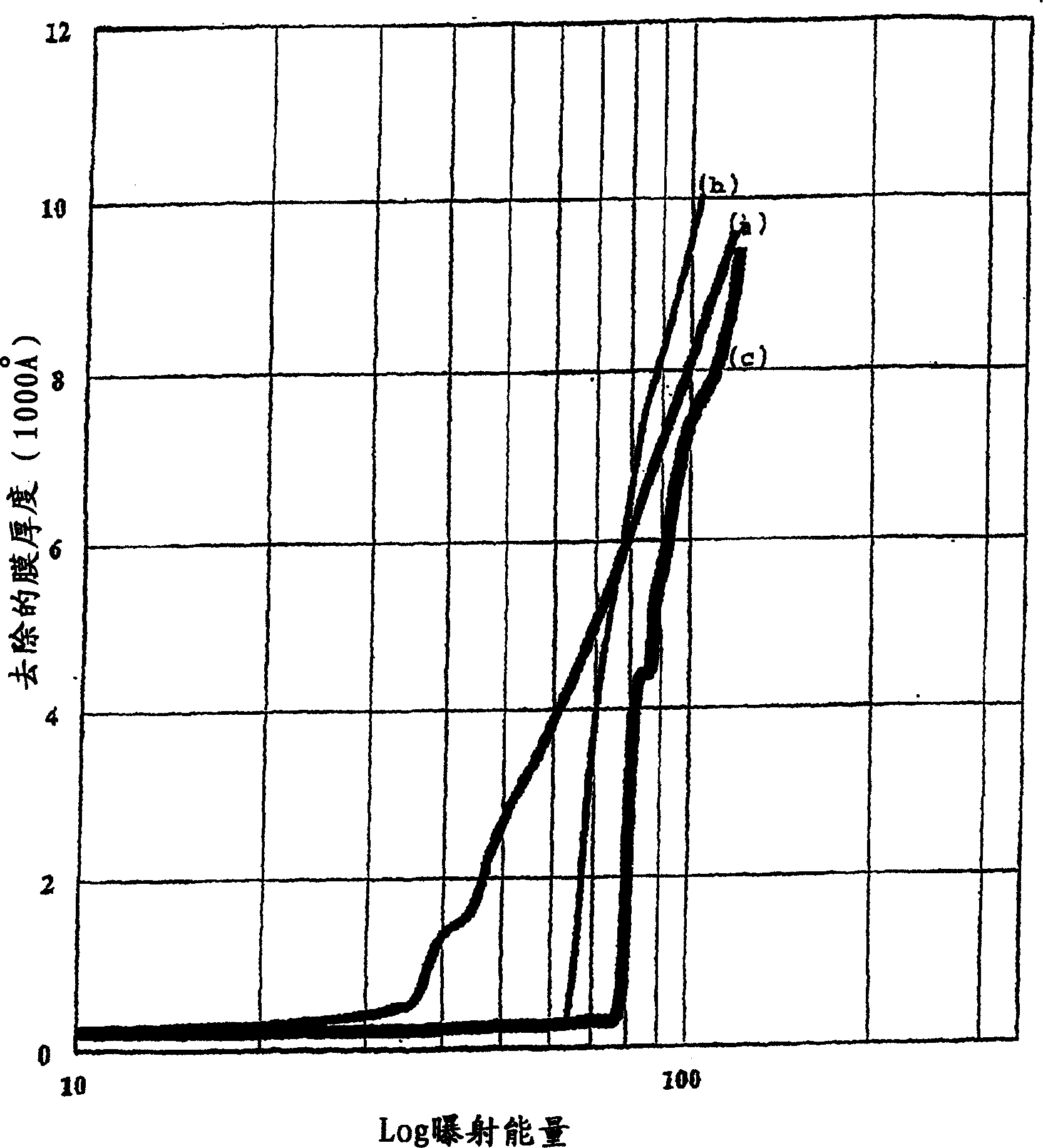

[0074] figure 1 is the removed film thickness versus exposure (exposure energy in millijoules / square centimeter (mJ / cm 2 ) graph of the logarithm of the measure). Curve (a) takes formulation A, curve (b) takes formulation B, and curve (c) takes formulation C from Example 1 above. The resin...

Embodiment 2

[0077] 5 Based on m-cresol / p-cresol / trimethylphenol, with use of AZ MIF-300 developer (0.261 N tetramethylammonium hydroxide (TMAH); obtained from AZ Electronic Materials, Clariant Company) unfractionated novolak resin with a dissolution rate of 550 Å / sec;

[0078] 6 Based on m-cresol, with the use of AZ MIF-300 developer (from AZ Electronic Materials, Clariant company) when the dissolution rate is the graded novolac resin of 113 Å / sec;

[0079] 7 Based on o-cresol, with the use of AZ MIF-300 developer (from AZ Electronic Materials, Clariant company) when the dissolution rate is 1017 Å / sec novolac resin (ungraded);

[0080] 8 Photoactive compound sensitizer - o-quinonediazide sulfonyl ester of a polyol represented by structure (VII) in the specification, wherein an average of 2.8 hydroxyl groups are esterified; available from AZ Electronic Materials, Clariant Corporation.

[0081] figure 2 is the removed film thickness versus exposure (exposure energy in ...

Embodiment 3

[0083] The formulations listed in Table 3 below were used to determine the dose to print (DTP) values listed in Table 4.

[0084] Element

E

G

H

I

J

K

L

M

MPT resin - fast 5

1.6

1.6

1.6

1.6

1.6

1.6

--

--

MPT resin - slow 7

--

--

--

--

--

--

1.6

1.6

meta resin - slow 6

0.4

0.4

0.4

0.4

0.4

--

0.4

--

Meta Resin - Fast 8

--

--

--

--

--

0.4

--

0.4

DR 167 9

0.60

--

--

--

--

--

--

--

DR 154 10

--

0.60

--

--

--

--

--

--

DR 153 / 155 11

--

--

0.60

--

--

--

--

--

DR 166 / 168 12

--

--

--

0.60

--

--

--

--

NK 280 13

--

--

--

--

0.60

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com