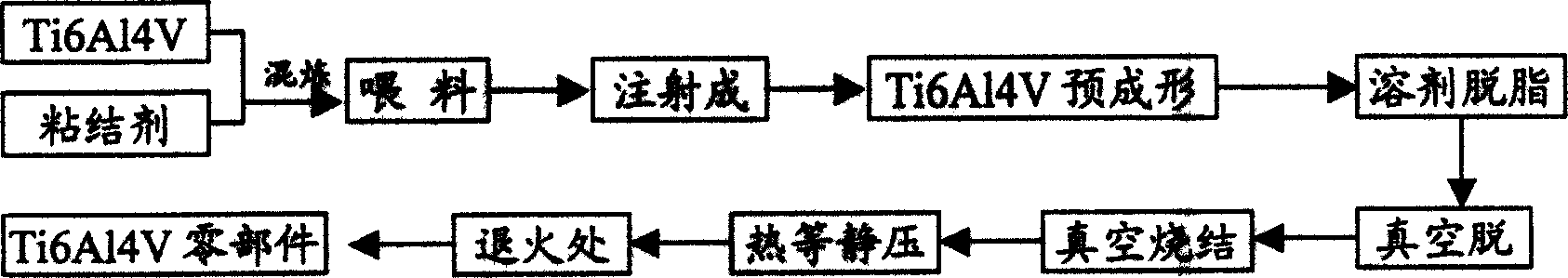

Ti6Al4V alloy injection forming method

A technology of injection molding and powder injection molding, which is used in the field of titanium alloy forming to achieve the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The ratio of hydrogenation-dehydrogenation Ti6Al4V: gas atomization Ti6Al4V is 1:9 to prepare the powder according to weight percentage, the binder is composed of 60% PW, 15% PEG20000, 15% LDPE, 10% PP and 0% SA, and the powder loading The volume is 68vol%. Mix the powder and binder on the SK-160 open rubber mixer for 1.5 hours, and then granulate on the PSJ32 mixing extruder to make the feeding more uniform. The feeding is in the CJ80- Injection molding on an E-type injection machine, the injection temperature is 120°C, the injection pressure is 80MPa, and the resulting injection blank is solvent degreased at 50°C for 2 hours in a mixed solvent of absolute ethanol and trichlorethylene (vol / vol=1.5:7.5) , and then dried at 40°C for 60 minutes and then placed in a vacuum degreasing furnace (10-3Pa) for thermal degreasing. The degreasing time was 8 hours, and the degreasing body was sintered in a vacuum sintering furnace (10-3Pa). The temperature is 1230°C, the sintering ...

Embodiment 2

[0017] The ratio of hydrogenation-dehydrogenation Ti6Al4V: gas atomization Ti6Al4V is 1:9 to prepare the powder according to the weight percentage. The binder is composed of 60% PW, 14% PEG20000, 15% LDPE, 10% PP and 1% SA. The volume is 68vol%. Mix the powder and binder on the SK-160 open rubber mixer for 1.5 hours, and then granulate on the PSJ32 mixing extruder to make the feeding more uniform. The feeding is in the CJ80- Injection molding on an E-type injection machine, the injection temperature is 130°C, and the injection pressure is 70MPa. The resulting injection blank is solvent-degreased at 50°C for 3 hours in a mixed solvent of absolute ethanol and trichlorethylene (vol / vol=1.5:7.5) , then dried at 40°C for 60 minutes and then placed in a vacuum degreasing furnace (10 -3 Pa) carried out thermal degreasing, and the degreasing time was 8 hours, and the degreasing body was placed in a vacuum sintering furnace (10 -3 Pa) for sintering, the sintering temperature is 1230°C...

Embodiment 3

[0019] The ratio of hydrogenation-dehydrogenation Ti6Al4V: gas atomized Ti6Al4V is 1:9 to prepare the powder according to the weight percentage. The binder is composed of 62% PW, 14% PEG20000, 12% LDPE, 9% PP and 3% SA. The powder loading The volume is 70vol%, the powder and the binder are mixed on the SK-160 open rubber mixer for 1.8 hours, and then granulated on the PSJ32 mixing extruder to make the feeding more uniform, and the feeding is in the CJ80- Injection molding on an E-type injection machine, the injection temperature is 130°C, the injection pressure is 80MPa, and the resulting injection blank is solvent degreased at 60°C for 2 hours in a mixed solvent of absolute ethanol and trichlorethylene (vol / vol=1.5:7.5) , then dried at 40°C for 30 minutes and then placed in a vacuum degreasing furnace (10 -3 Pa) carried out thermal degreasing, and the degreasing time was 7 hours, and the degreasing body was placed in a vacuum sintering furnace (10 -3 Pa) for sintering, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com