Cryogenic temperature cool storage device and refrigerator

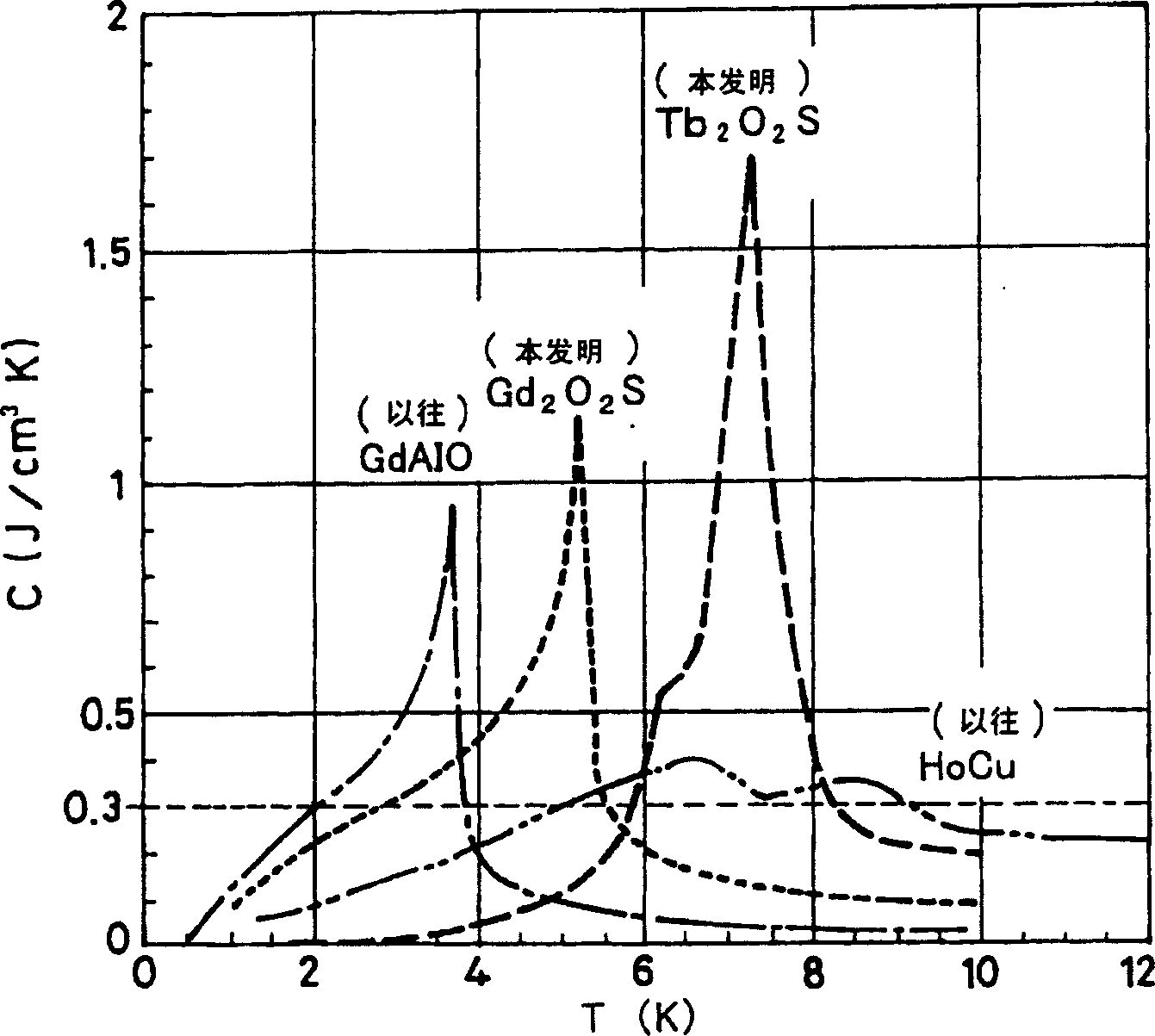

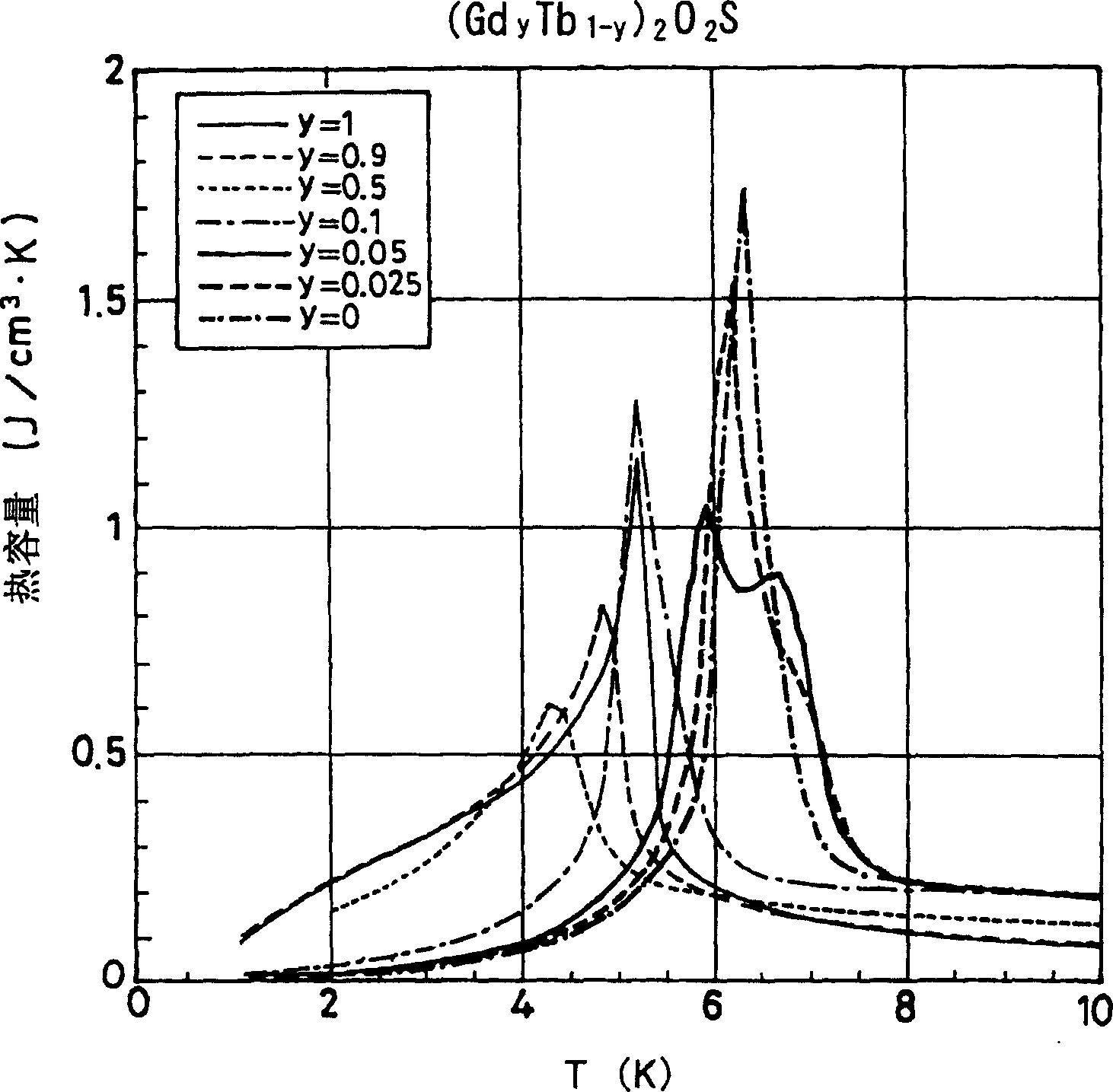

An extremely low temperature, regenerator technology, applied in refrigerators, gas cycle refrigerators, compressors, etc., can solve the problems of insufficient specific heat, insufficient refrigeration capacity, and high manufacturing cost of metal-based magnetic regenerator materials, and achieve improvement. The effect of freezing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

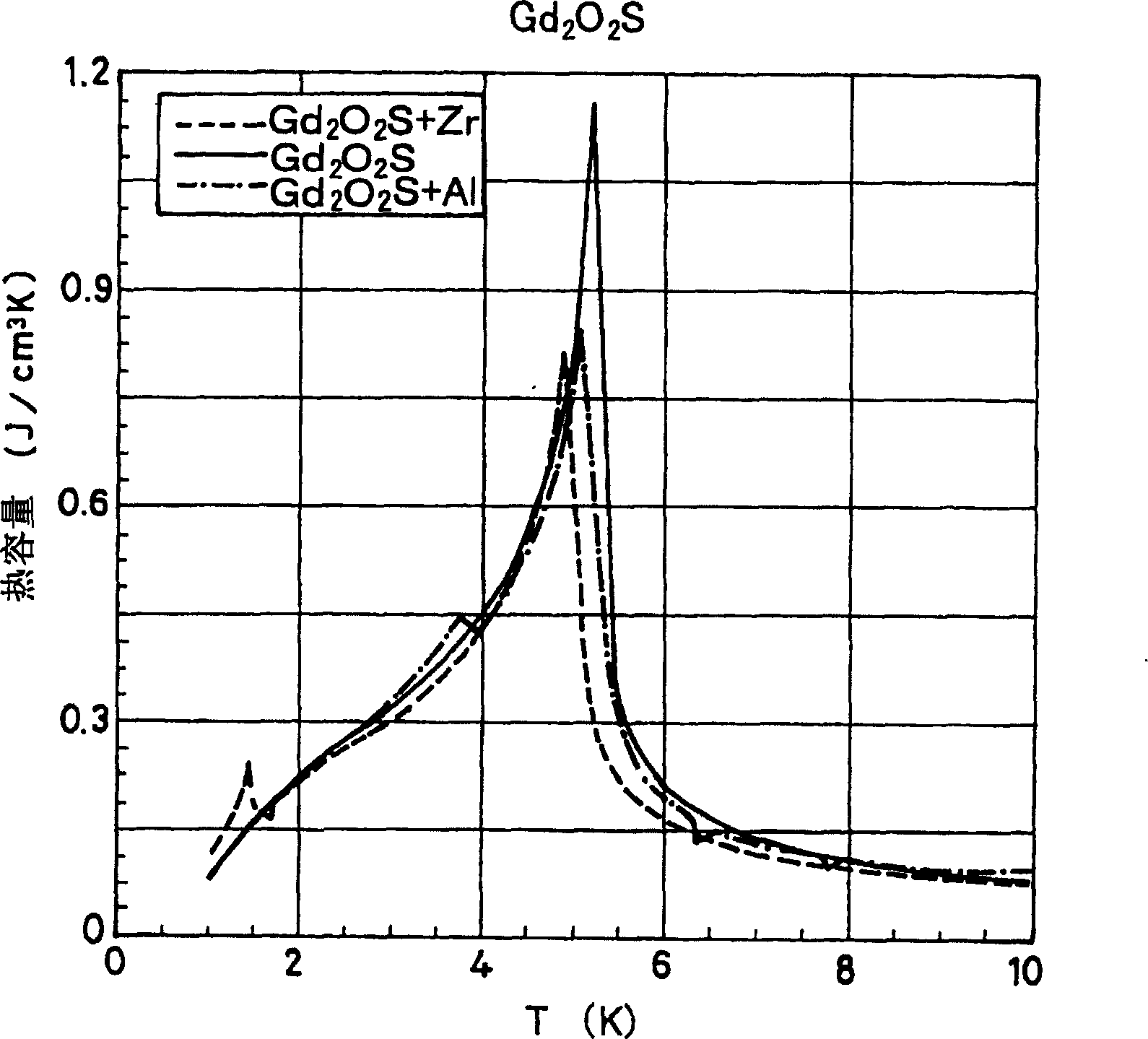

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0050] The first embodiment of the present invention is as Figure 4 (overall picture), Figure 5 (detailed drawing of the cooling unit) and Figure 6 As shown in (Cross-sectional view of two-stage regenerator), the present invention is applied to a two-stage GM refrigerator.

[0051] exist Figure 4 Among them, the high-pressure gas from the compressor 11 is supplied to the two-stage GM refrigerator 1 through the high-pressure gas piping 12 , and is recovered to the low-pressure port of the compressor 11 through the low-pressure gas piping 13 . Such as Figure 5 As shown, the first-stage regenerator 2 and the second-stage regenerator 3 housed in the first-stage hydraulic cylinder 25 and the second-stage hydraulic cylinder 35, respectively, are Figure 4 The drive motor 14 shown is driven to reciprocate up and down.

[0052] Cold storage materials 24, 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com