Flexible coatings for elastomer substrates

A technology of elastomer and coating composition, which is applied in coatings, carboxyl rubber coatings, conjugated diene coatings, etc., and can solve the problems of vulcanized rubber aging and recovery sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0243] The following examples were prepared using Zetpol 2220, an X-HNBR polymer produced by Zeon Chemical with an acrylonitrile content of 36% and an unsaturation of 5 mole%. A suitable commercial substitute is Theban _ KA 8889.

[0244] The elastomer coating solution was prepared as follows:

[0245] Ingredient Description PHR

[0246] X-HNBR carboxylated hydrogenated nitrile-butadiene 100.0

[0247] This formulation is soluble in methyl isobutyl ketone (MIBK, CAS No. 108-10-1) with a solids content of 12.0% by weight.

[0248] To 40 grams of the solution was added 0.1 g, 0.5 g and 1.0 g of a 53% solution of bis-[isocyanatophenyl]methane (diisocyanate) in xylene. At 0.1 g of diisocyanate, the solution solidifies in less than 16 hours at room temperature. At 0.5 g, the solution solidified within 30 minutes.

[0249] To 40 grams of the solution were added 0.3, 0.7, 1.0 and 1.3 grams of 3-isocyanatopropyltriethoxysilane, CAS# 24801-88-5. At all levels, the coating compos...

Embodiment 2

[0281] Use Therban from Bayer AG _ Therban in trademark _ The following examples were prepared from KA 8889 obtained X-HNBR polymer.

[0282] The elastomer coating solution was prepared as follows:

[0283] Ingredient Description PHR

[0284] X-HNBR carboxylated hydrogenated nitrile-butadiene 100.0

[0285] This formulation is soluble in methyl isobutyl ketone (MIBK, CAS No. 108-10-1) with a solids content of 15.0% by weight.

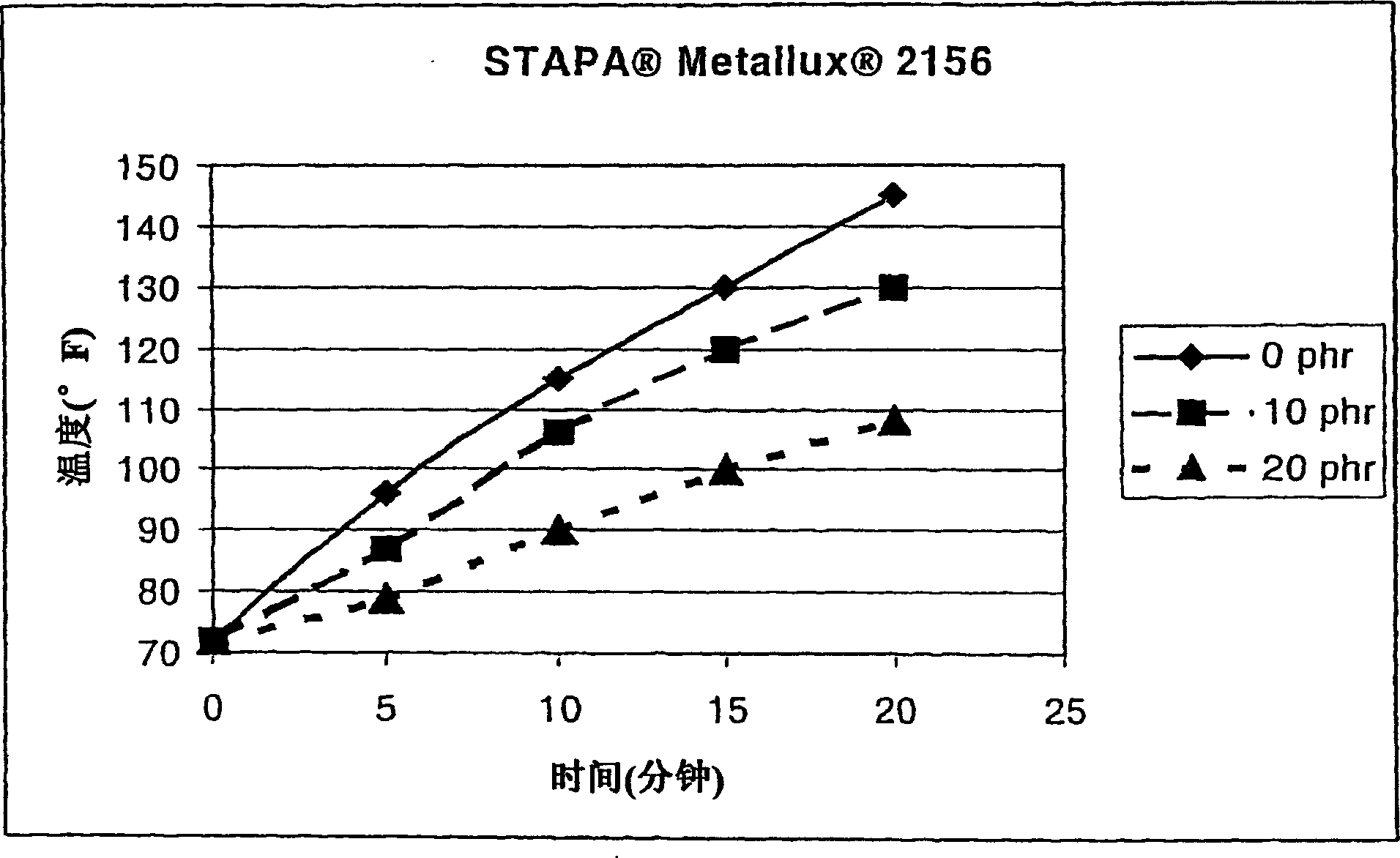

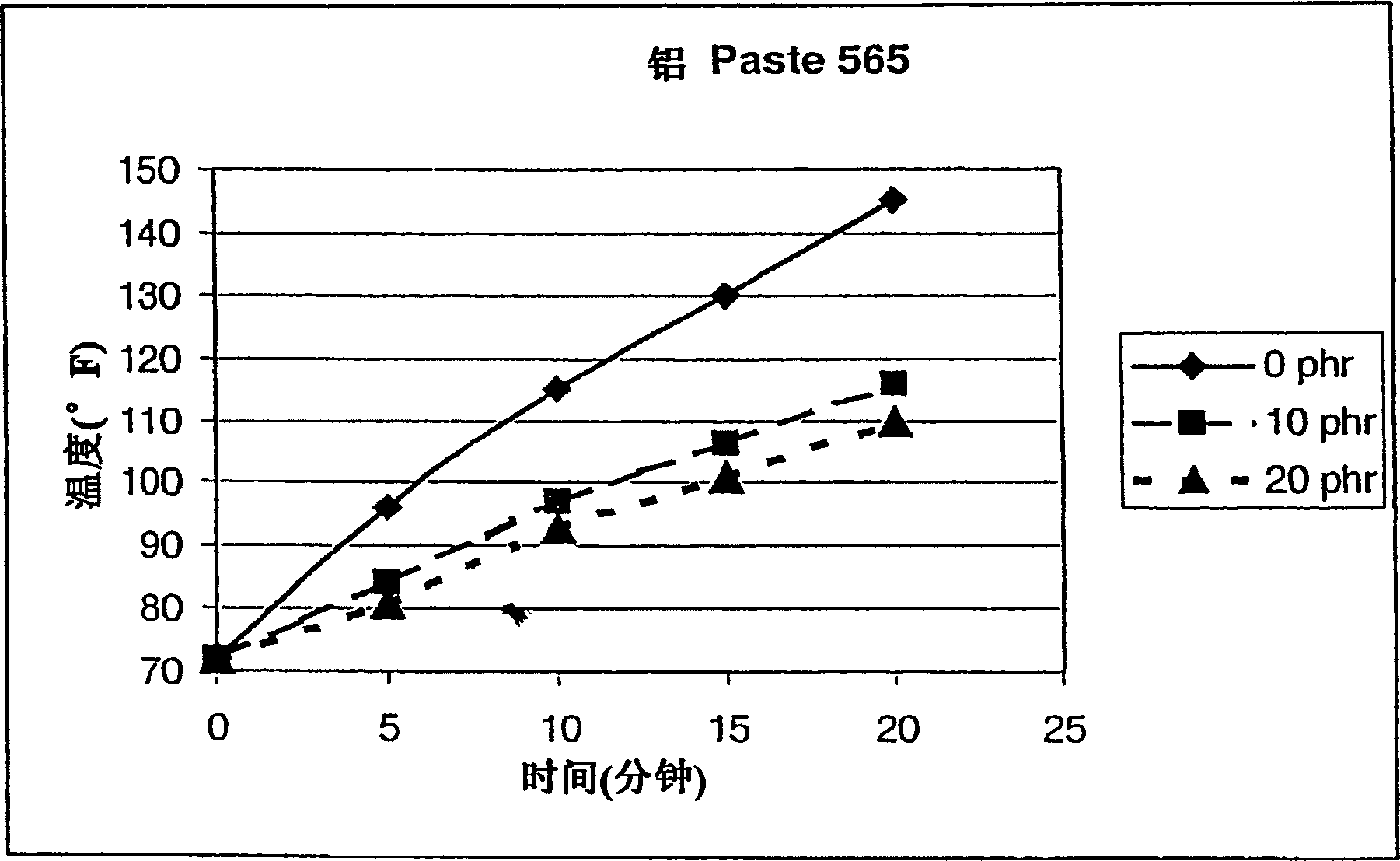

[0286] 33 phr thin aluminum flakes with an average particle diameter of 16 microns were added to the coating solution.

[0287] In the solution of 97.5 wet weight parts, add the bis-[isocyanatophenyl] methane (diisocyanate) (Casabond _ TX, 53% in xylene).

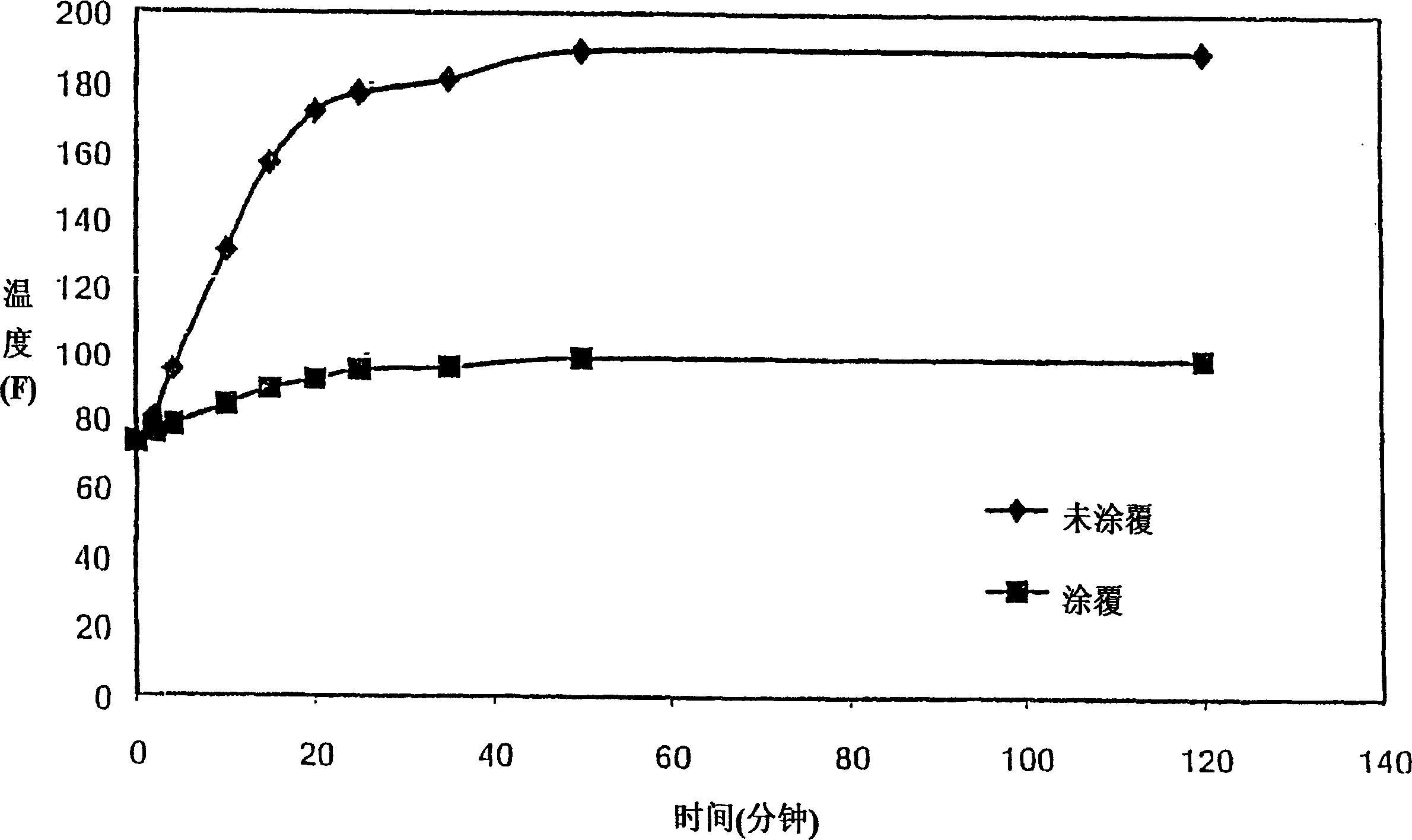

[0288] A cured block of natural rubber 3″×3″×0.5″ (7.6cm×7.6cm×1.2cm) with a hardness A of 65 was applied to a dry film thickness of about 1 mil ( ).

[0289]A hole was drilled in the center of the block, 1.5 inches (3.8 cm), and a thermocouple was inserted to monitor the temperature. The blo...

Embodiment 3

[0308] Example 3 - Functionalized HNBR water-based latex

[0309] Element

Recipe 1

Recipe 2

Recipe 3

Recipe 4

Recipe 5

Recipe 6

41% solids X-

HNBR latex

100 g

100 g

100 g

100 g

100 g

100 g

diphenylmethane diiso

1 (aromatic)

1.25 grams

2.5 grams

5.0 grams

-

-

-

1,6-hexamethylene di

Polyisocyanate

2 (aliphatic)

-

-

-

2.5 grams

5.0 grams

7.5 grams

[0310] 1 Desmodur _ XO 672

[0311] 2 Bayhydur _ 302 (1,6-HDI), available from Bayer Corporation

[0312] DeMattia flex samples were sprayed with the latex / isocyanate mixture listed above. The DeMattia sample was wiped with MIBK and stained with Chemlok _ 7701 treatment, the coating i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com