Acetic acid refining method for improving acetic acid potassium permanganate test time

A technology of potassium permanganate and test time, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems that saturated aldehydes cannot be decomposed, shorten the test time of potassium permanganate, etc., and extend the time for discoloration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

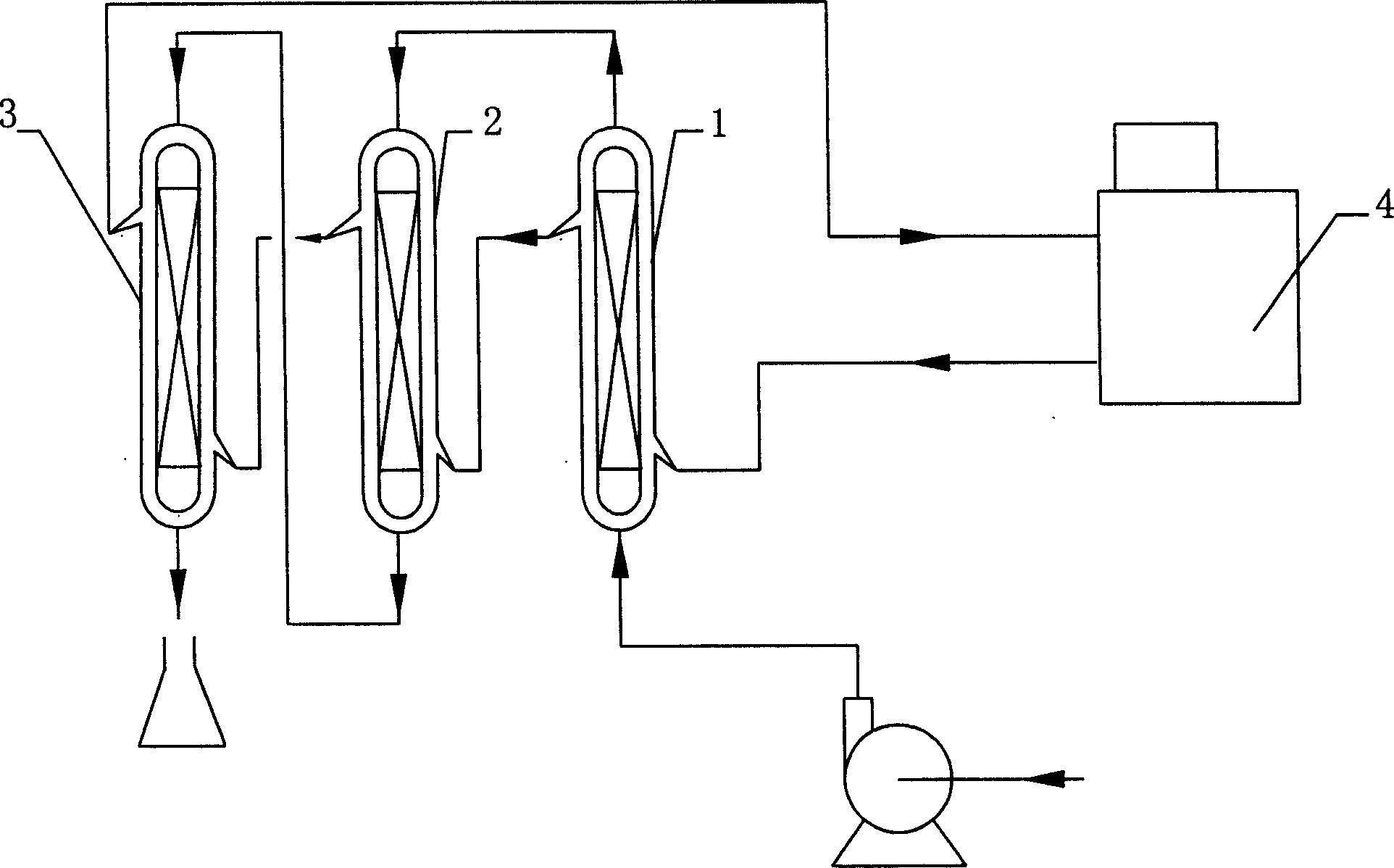

[0025] The process flow of the refining process is shown in the accompanying drawing. The product acetic acid is injected into the adsorption column 1 equipped with 108g potassium bromate through a peristaltic pump, and the speed is controlled at 0.24ml / s. The acetic acid passes through the adsorption column 1 from bottom to top, and then enters the adsorption column 1 equipped with 100.51 The adsorption column 2 of g activated carbon enters the adsorption column 3 that 16g activated carbon is housed at last, and the temperature is controlled at 60 ℃ by the heating thermostat 4, and the acetic acid obtained by the adsorption column 3 is the product obtained.

Embodiment 2

[0027] The acetic acid product that embodiment 1 obtains is carried out potassium permanganate test, the water of getting 6ml and the acetic acid of 20ml are added test tube, then the potassium permanganate solution of 3ml is added dropwise, after fully shaking, leave standstill, observe its discoloration time.

[0028] The acetic acid product that embodiment 1 obtains is carried out product analysis.

[0029] Methyl iodide (ppb)

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com