Method for manufacturing specified nickel powder for welding electrode by machinery crushing method

A technology of mechanical crushing and welding rods, applied in the field of nickel powder production, can solve the problems of difficulty in meeting the requirements of powder for welding rods, fine nickel powder, etc., and achieve the effects of improved welding performance, low cost and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

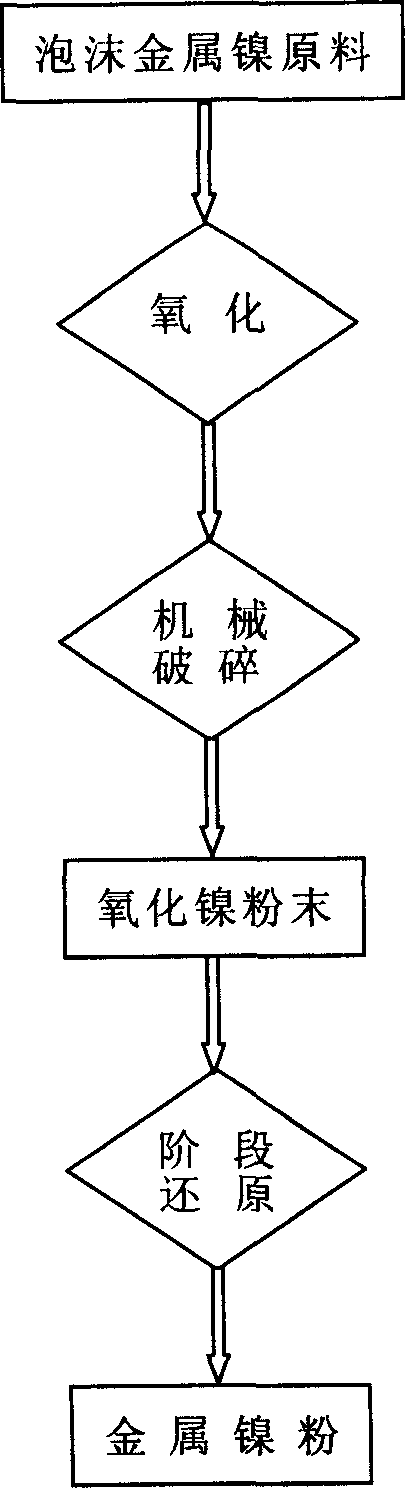

Image

Examples

Embodiment 1

[0018] Embodiment 1. a kind of method that adopts mechanical crushing method to produce the special nickel powder of electric welding rod, its method is:

[0019] A dynamic rotary oxidation furnace is used to continuously oxidize the nickel foam raw material, the oxidation temperature is 860°C, the oxidation time is 25min, and the rotation speed of the oxidation furnace is 35rpm. After the primary oxidation, the oxidation product is crushed by a multi-stage mechanical crusher, and the deformed martensitic strengthened steel Mn13 is used as the material for the mechanical crushing blade in the mechanical crusher. The crushing time is 20 minutes, and the crushing level is 1. Subsequently, the mechanically crushed product was subjected to secondary oxidation. The equipment used was a dynamic rotary oxidation furnace, the oxidation temperature was 880°C, the oxidation time was 20 minutes, and the rotation rate of the oxidation furnace was 35 rpm. The secondary oxidized nickel oxi...

Embodiment 2

[0020] Embodiment 2. a kind of method that adopts mechanical crushing method to produce the special nickel powder of electric welding rod, its method is:

[0021] A dynamic rotary oxidation furnace is used to continuously oxidize the nickel foam raw material, the oxidation temperature is 900°C, the oxidation time is 15min, and the rotation speed of the oxidation furnace is 25rpm. After the primary oxidation, the oxidation product is crushed by a multi-stage mechanical crusher, and the material used for the mechanical crushing blade in the mechanical crusher is the deformed martensitic strengthened steel Mn13. The crushing time is 20 minutes, and the number of crushing stages is 2. Subsequently, the mechanically crushed product was subjected to secondary oxidation. The equipment used was a dynamic rotary oxidation furnace, the oxidation temperature was 870° C., the oxidation time was 15 minutes, and the rotation rate of the oxidation furnace was 30 rpm. The secondary oxidized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com