Semiconductor device

A semiconductor and conductive technology, applied in the field of ohmic connectivity components and semiconductor devices, can solve problems such as voltage difference and uneven operation, achieve uniform operation, suppress voltage drop, and ensure the number of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, refer to Figure 1 to Figure 9 A detailed description will be given of the semiconductor device and its manufacturing method of the present invention.

[0030] Example.

[0031] First, refer to Figure 1 ~ Figure 4 The semiconductor device of this embodiment will be described.

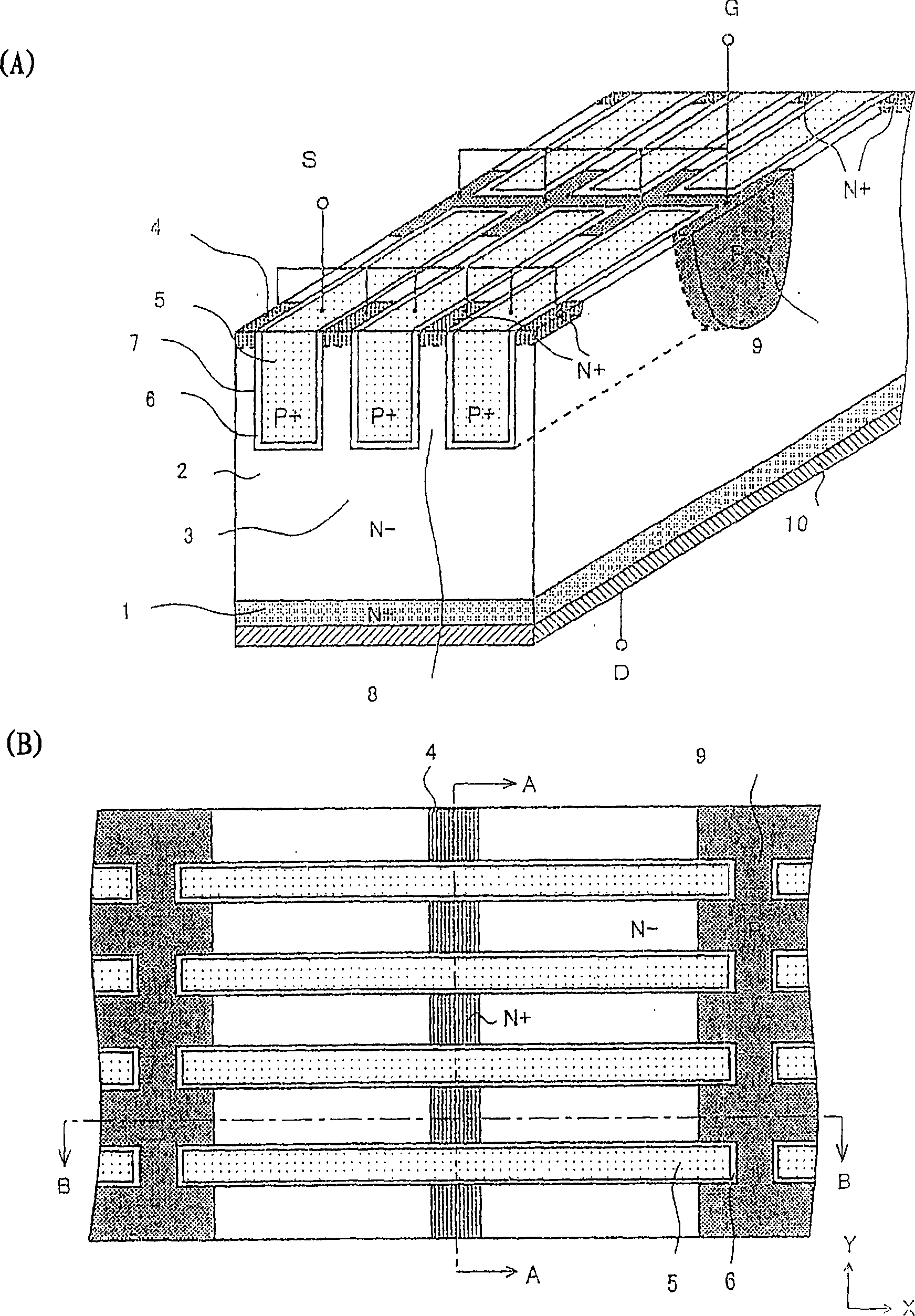

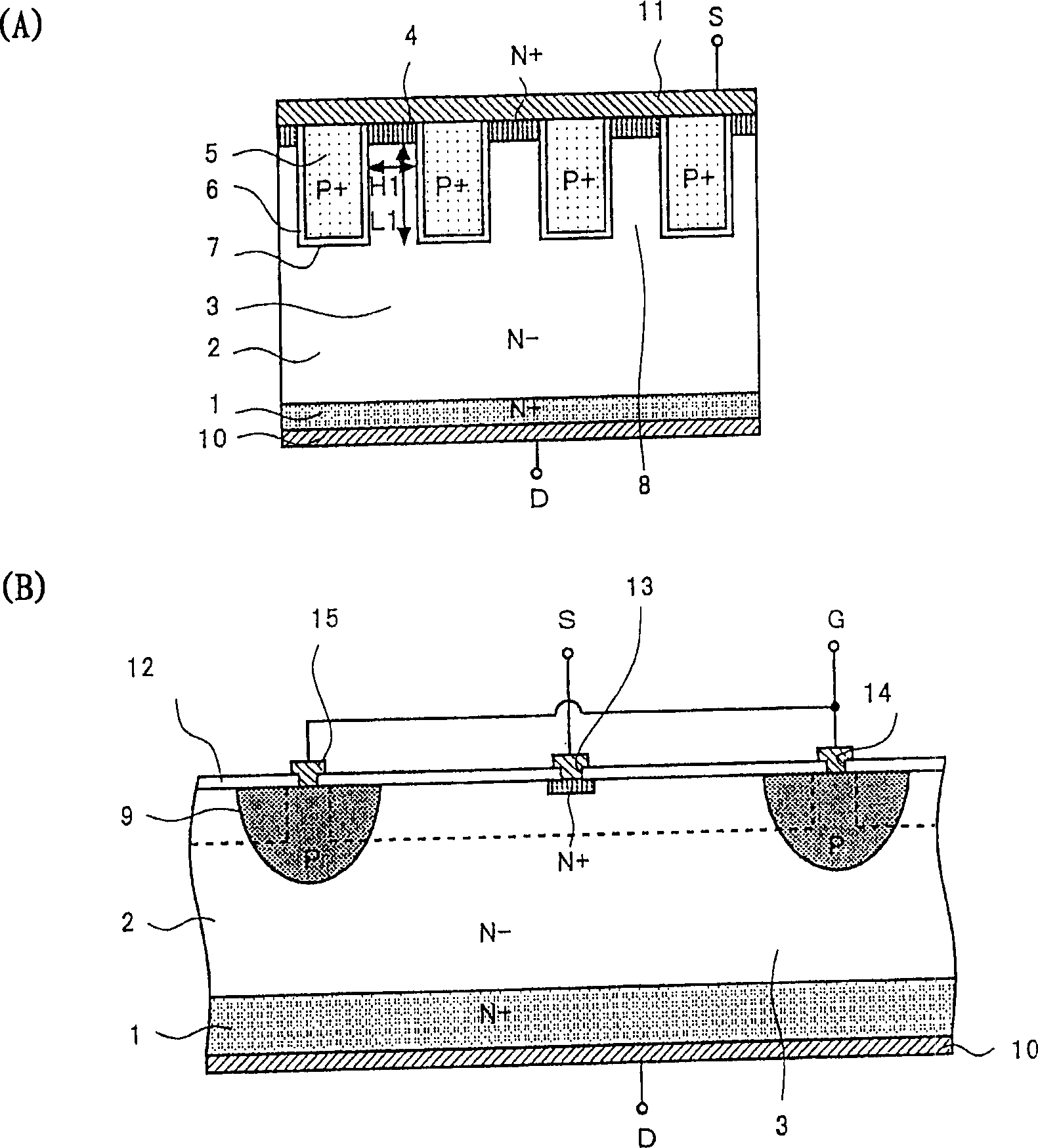

[0032] figure 1 (A) is a perspective view showing the structure of the semiconductor device of the present invention, figure 1 (B) is a top view showing the structure of the semiconductor device of the present invention. Such as figure 1 As shown in (A), an N-type epitaxial layer 2 is deposited on an N-type semiconductor substrate 1 . A plurality of grooves 7 are formed from the surface of the epitaxial layer 2 . The grooves 7 are arranged parallel to each other at equal intervals. The substrate 1 is used as a drain extraction region, and the epitaxial layer 2 is mainly used as a drain region 3 . In addition, the side walls of the groove 7 are etched substantially perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com