Method for preparing pumpkin polysaccharide

A technology of pumpkin polysaccharides and pumpkins, which is applied in the field of diabetes prevention and treatment products, and can solve problems such as troublesome eating and large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

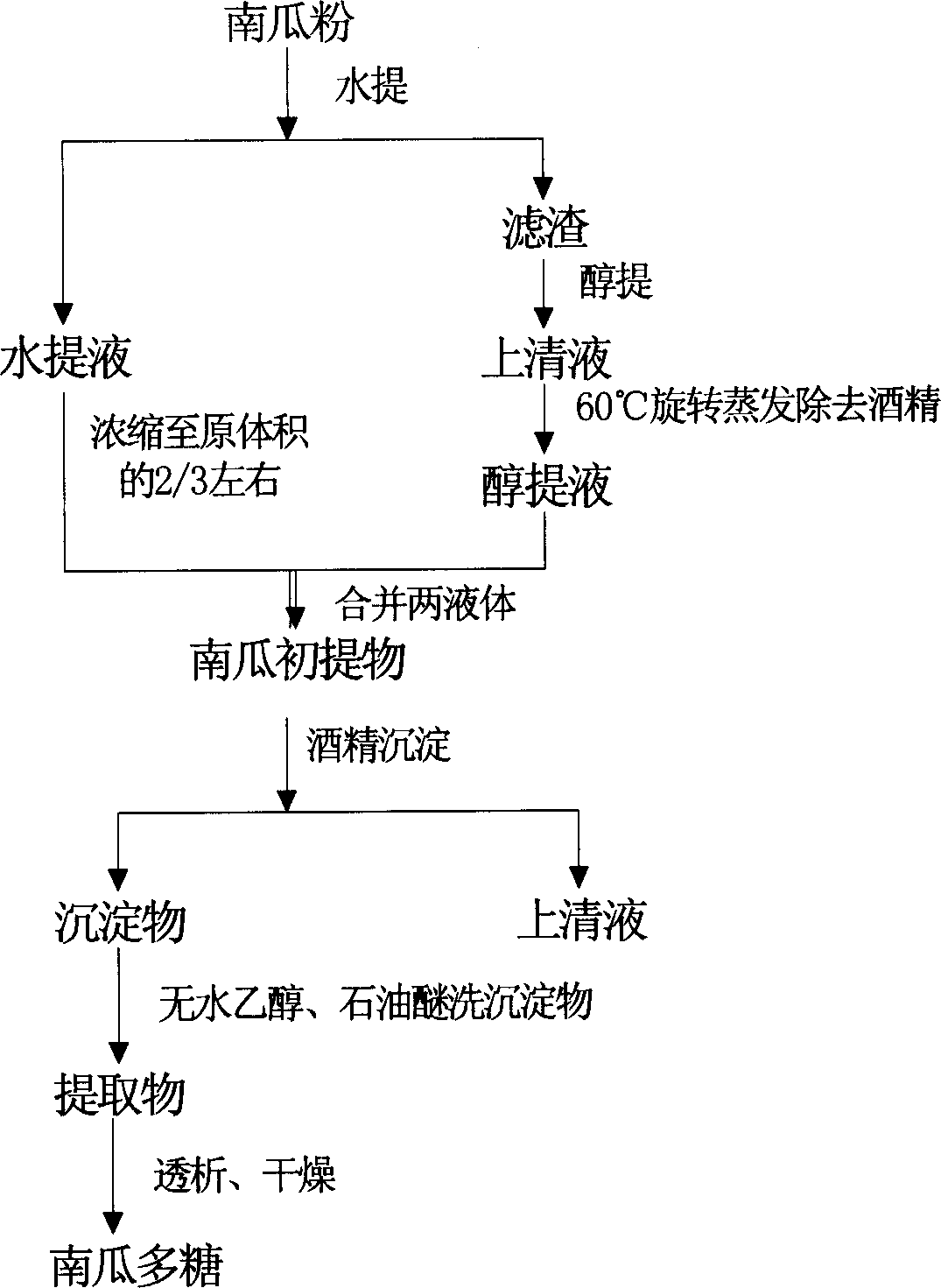

Method used

Image

Examples

Embodiment 1

[0012] Pumpkin powder is extracted with hot water, the extraction temperature is 50°C, the extraction time is 4 hours, the ratio of material to water is 1:8, after extraction, it is filtered, the filtrate is recovered, the filter residue is extracted with 95% ethanol for 48 hours, and the filtrate is collected, and the two filtrates are combined. To obtain the pumpkin primary extract, use 95% ethanol to precipitate the pumpkin primary extract at a ratio of 5:1 between ethanol and pumpkin primary extract, centrifuge to take the precipitate, wash it with absolute ethanol and petroleum ether in sequence, and then add 1 times the volume of 10 % trichloroacetic acid, stirred gently at room temperature and put it in the refrigerator overnight, centrifuged, discarded the precipitate, concentrated under reduced pressure, put it into a dialysis bag for dialysis against water for 1 day, double distilled water for 2 days, and took out and dried pumpkin polysaccharide.

Embodiment 2

[0014] Pumpkin powder is extracted with hot water, the extraction temperature is 80°C, the extraction time is 2 hours, the ratio of material to water is 1:10, after extraction, it is filtered, the filtrate is recovered, the filter residue is extracted with 95% ethanol for 30 hours, and the filtrate is collected, and the two filtrates are combined. To obtain the primary extract of pumpkin, use 95% ethanol to precipitate the primary extract of pumpkin according to the ratio of ethanol to the primary extract of pumpkin at a ratio of 3:1, centrifuge to take the precipitate, wash it successively with absolute ethanol and petroleum ether, and then add 1 times the volume of 10 % trichloroacetic acid, stirred gently at room temperature and put it in the refrigerator overnight, centrifuged, discarded the precipitate, concentrated under reduced pressure, put it into a dialysis bag for dialysis against water for 1 day, double distilled water for 2 days, and took out and dried pumpkin polys...

Embodiment 3

[0016] Pumpkin powder is extracted with hot water, the extraction temperature is 40°C, the extraction time is 5 hours, the ratio of material to water is 1:7, after extraction, it is filtered, the filtrate is recovered, the filter residue is extracted with 95% ethanol for 45 hours, and the filtrate is collected, and the two filtrates are combined. Obtain the primary extract of pumpkin, use 95% ethanol to precipitate the primary extract of pumpkin according to the ratio of ethanol to the primary extract of pumpkin 4:1, centrifuge to take the precipitate, wash it with absolute ethanol and petroleum ether in sequence, and then add 1 times the volume of 10 % trichloroacetic acid, stirred gently at room temperature and put it in the refrigerator overnight, centrifuged, discarded the precipitate, concentrated under reduced pressure, put it into a dialysis bag for dialysis against water for 1 day, double distilled water for 2 days, and took out and dried pumpkin polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com