Apparatus for processing fiber-reinforced composites using fiber mat and its manufacture

A composite material and fibrillation technology, which is used in the equipment and manufacturing fields of fiber-reinforced composite materials using fiber mats, can solve the problem of uneven thickness and surface smoothness of composite materials, difficult board tension, and inability to change the direction of melt flow. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

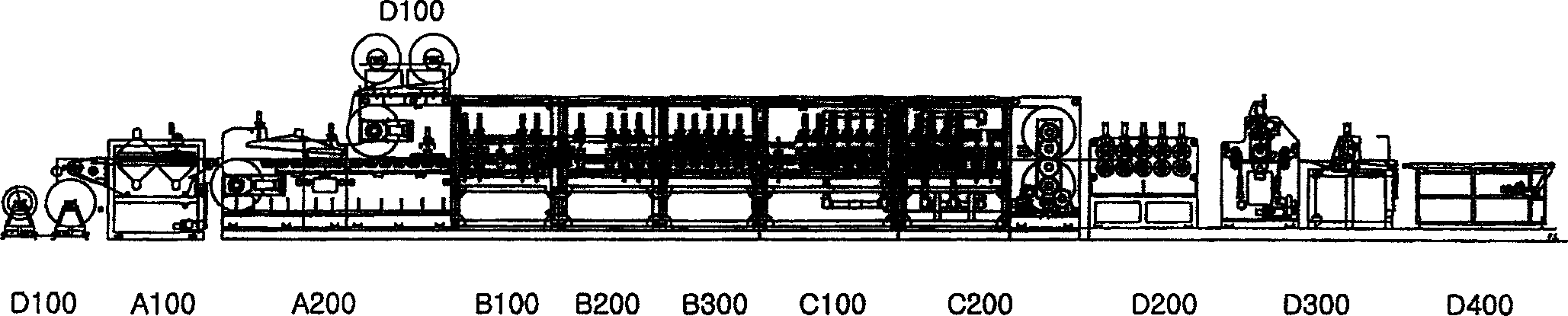

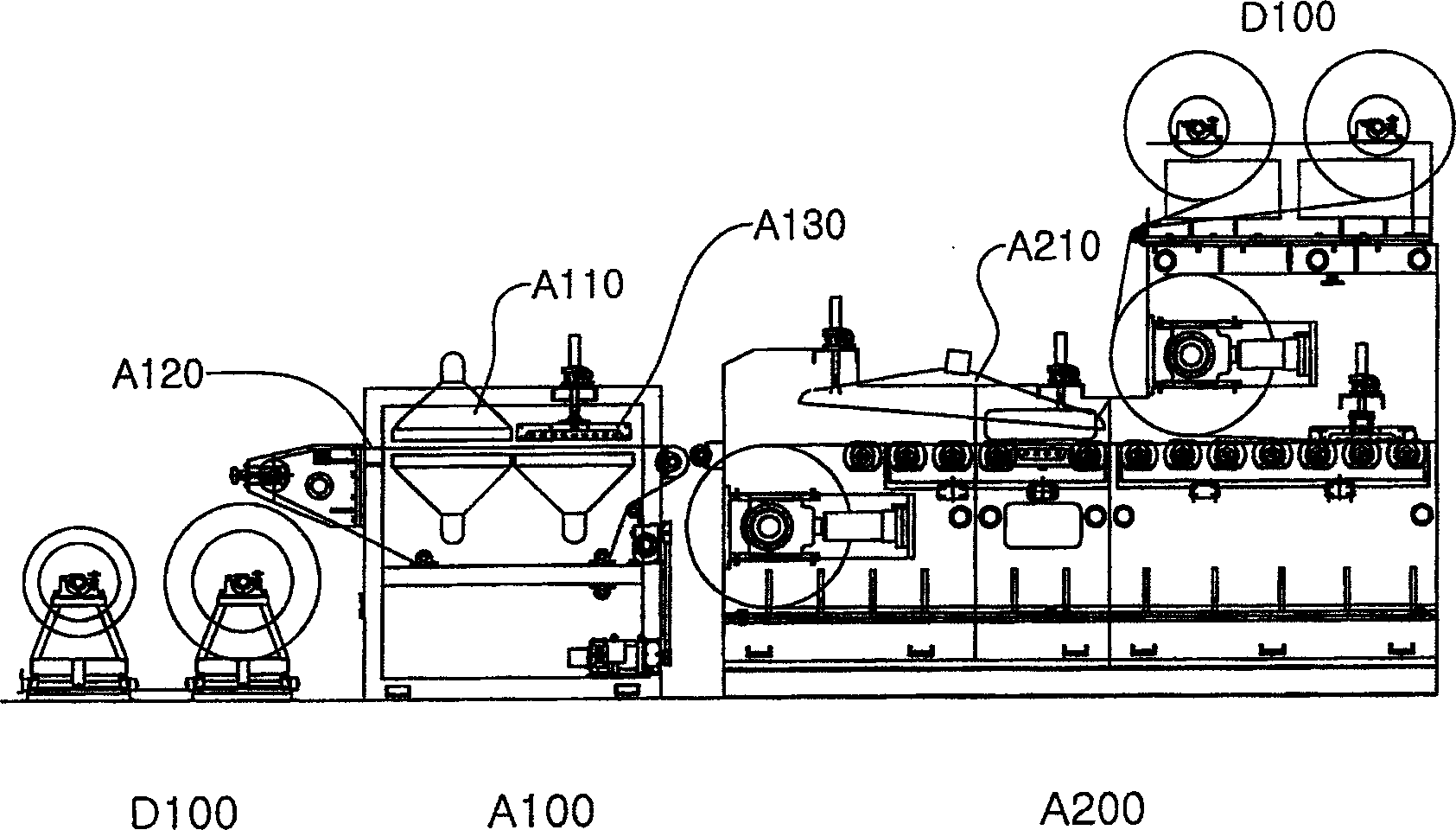

[0031] Referring now to the drawings, in which the same reference numerals are used to designate the same or similar parts in the different figures.

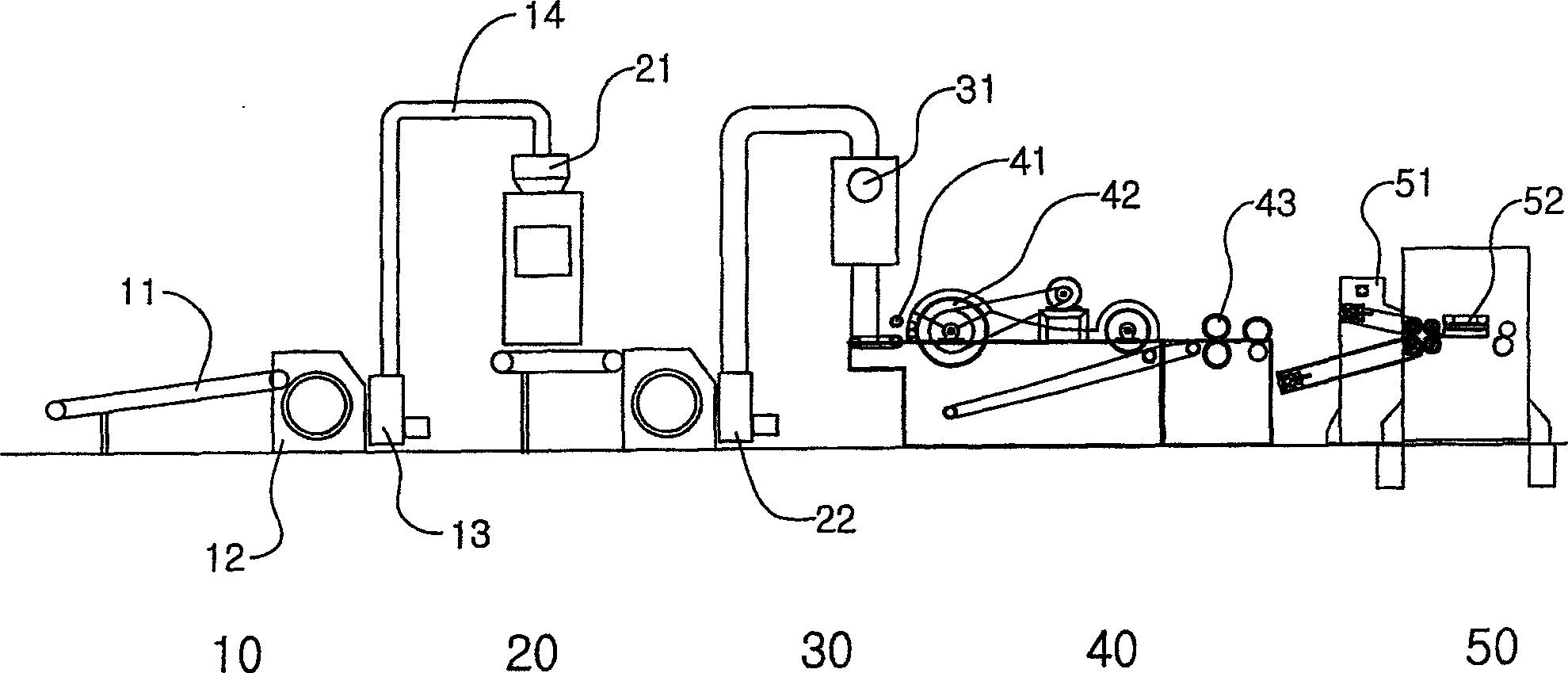

[0032] figure 1 A composite mat feeding device according to the invention is shown. Such as figure 1 As shown in , the composite feeding device includes a fibrillation mechanism 10 , a bonding mechanism 20 , a weighing mechanism 30 , a weaving mechanism (webber machine) 40 and a needle-punching mechanism 50 .

[0033] In this figure, the fibrillation mechanism 10 has a conveying part for conveying the fibers to be used to a predetermined position, wherein the conveying part comprises: a conveying belt 11 for regularly conveying weighed two types of fibers A fibrillating drum 12 for properly fibrillating the fibers conveyed by the conveyor belt 11; a suction section 13 for smoothly sucking fibrillated fibers into the pipeline 14; a dispersion section 21 , so that the fibers in the suction duct 14 can fall therein evenly;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com