Method for producing transparent conductive film

A technology of transparent conductivity and transparent conductive film, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems such as bubbles and deformation of transparent conductive film, so as not to reduce the display quality, The effect of suppressing the number of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

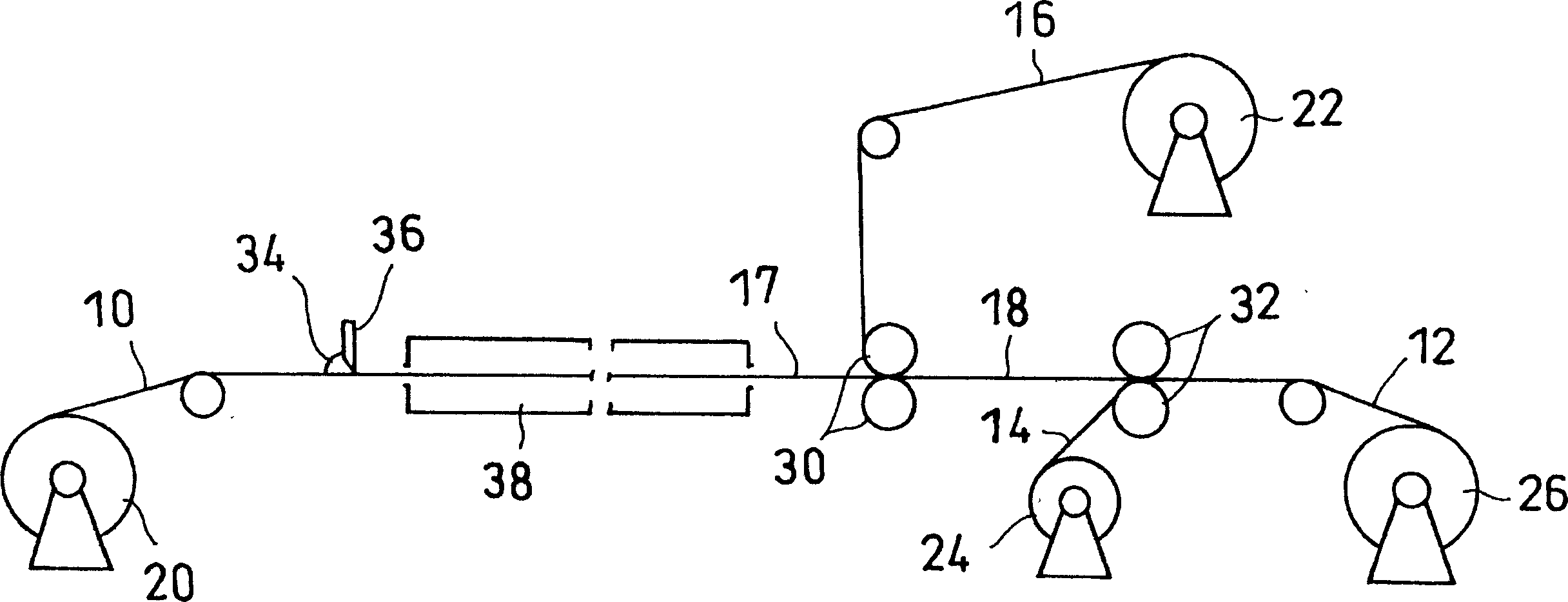

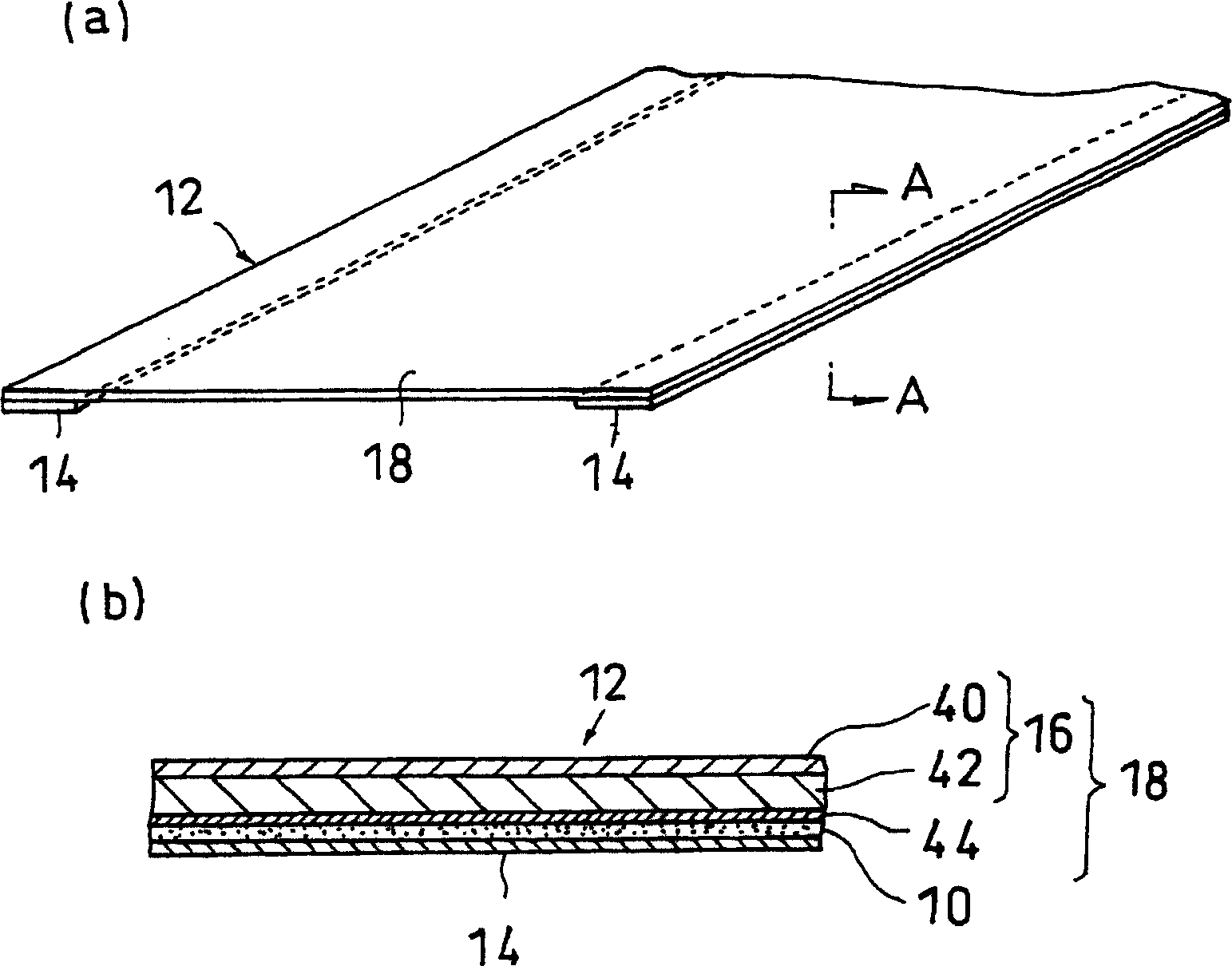

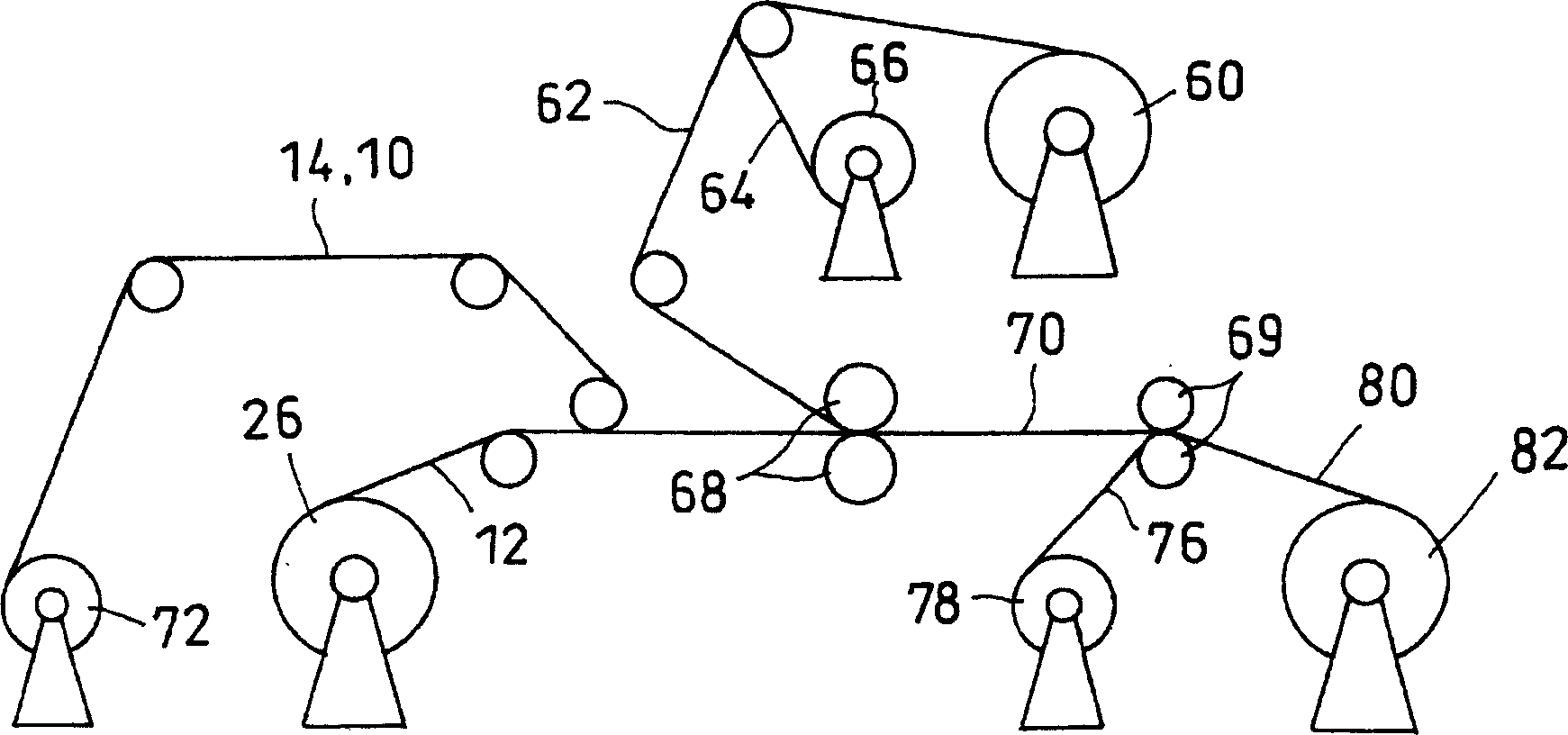

[0053] An HC film (first film) having a 5-μm-thick hard-coat treatment layer made of acrylic urethane resin on the first surface of a 125-μm-thick PET film (first substrate) was obtained.

[0054] An acrylic adhesive layer with a thickness of 25 μm was formed on a spacer with a thickness of 38 μm using a spray-type coater, and adhered to the first base material of the first film, that is, the PET film without a hard coat treatment layer. On the surface (second surface), it is used as an HC film adhesive product (the first film with an adhesive layer). A polyolefin-based co-extruded protective film with a 20mm wide adhesive layer is inserted into both ends of the HC film adhesive in such a way that it adheres to the spacer (adhesion force: 30mN based on JIS-Z-1552 / 25mm), take up HC film adhesive products.

[0055] Form an ITO film (second film) by forming an ITO vapor-deposited film on the first surface of a PET film (second substrate) with a thickness of 23 μm, and insert a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com