Process for the treatment of molybdenum concentrate

A process and technology of copper concentrate, applied in the field of copper-molybdenum concentrate treatment, can solve problems such as low recovery rate of molybdenum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

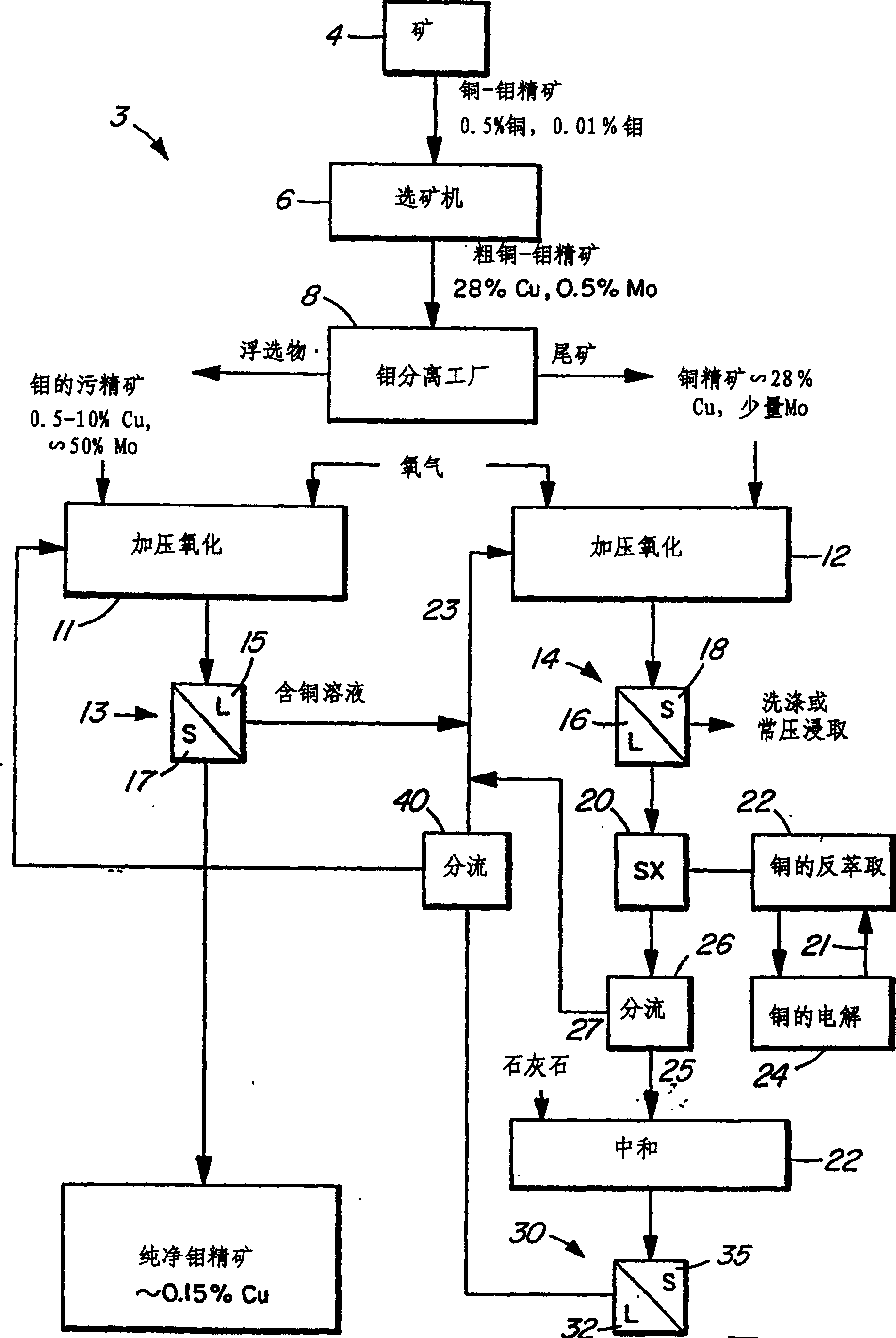

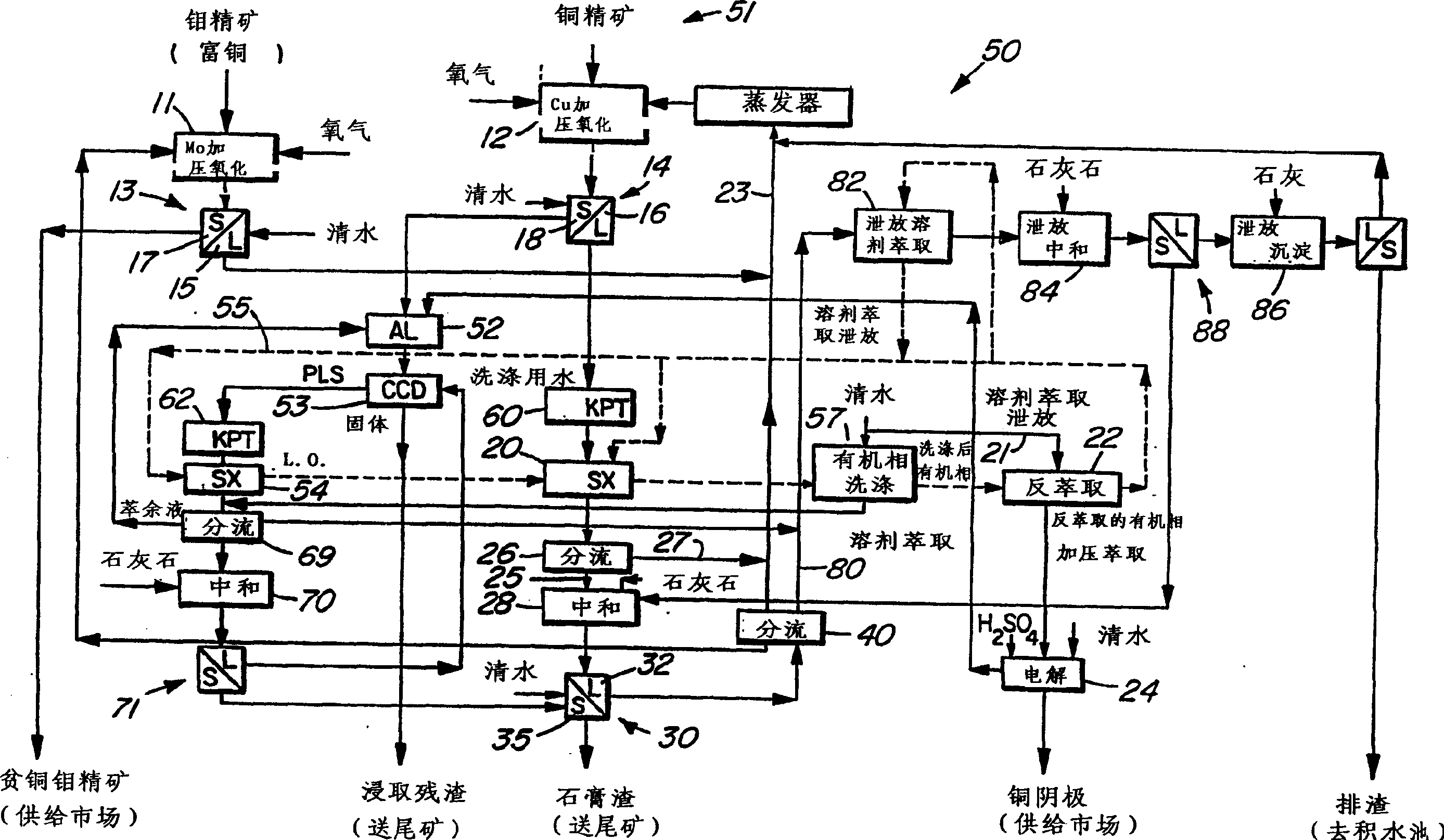

Method used

Image

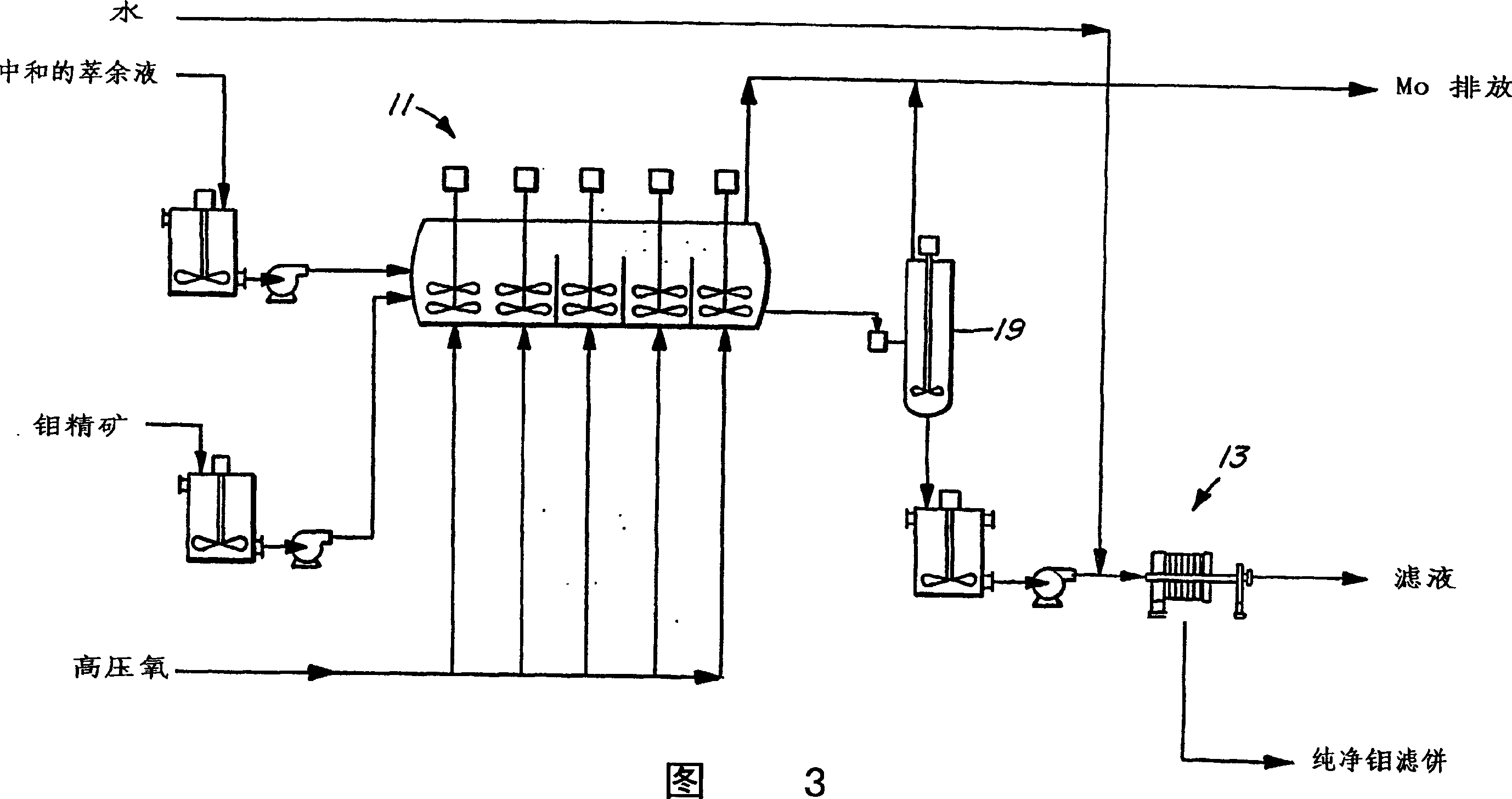

Examples

Embodiment 1

[0062] Molybdenum concentrate containing 45.2% Mo, 3.6% Cu, 3.6% Fe and 34.2% total sulfur, after pressure oxidation (solid content during pressure oxidation is 500g / L), the feed liquid used contains 15g / L Cu , 12g / L Cl, and 20g / L free acid. The pressurized oxidation was carried out at 150° C. under a total pressure of 200 psig (1480 kPa) for one hour.

[0063] After pressure oxidation, the product slurry was filtered and the residue was washed with water. The pH of the filtrate was 0.91. The filtrate contained 31.34g / L Cu, 3.64g / L Mo and 5.87g / L Fe. The extraction rates of copper and molybdenum were 96.2% and 1.6% respectively (extraction rate of copper was based on solid; extraction rate of molybdenum was based on solution).

Embodiment 2

[0065] In another experiment, the same Mo concentrate was oxidized under pressure under the same conditions as above, except that the feed liquid used did not contain free acid. The pH value of the filtrate after pressure oxidation was 1.06. The filtrate contained 33.04g / L Cu, 6.64g / L Mo and 7.24g / L Fe. The extraction rates of copper and molybdenum are 95.2% and 2.7% respectively.

Embodiment 3

[0067] In another experiment, the same Mo concentrate was oxidized under pressure under the same conditions as above. The difference is that the feed liquid used contains 30g / L free acid. The pH value of the filtrate after pressure oxidation was 1.03. The filtrate contained 30.60 g / L Cu, 3.04 g / L Mo and 6.16 g / L Fe. The extraction rates of copper and molybdenum were 94.1% and 1.3%, respectively.

[0068] It can be seen from the above three examples that the extraction rate of copper is high, while the extraction rate of molybdenum (representing the loss of molybdenum in the molybdenum concentrate) is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com