Power unit structure for hybrid vehicle

一种混合动力车、动力单元的技术,应用在混合动力车辆、机动车、电动汽车等方向,能够解决难于保证减速比、电机尺寸增大等问题,达到提高可保养性和可触及性、缩短纵向长度、减小尺寸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] An embodiment of the invention will be described with reference to the accompanying drawings, wherein like elements are designated with like numerals throughout the several views. In the following description, "front" indicates the direction in which the vehicle is advancing, and "right" and "left" indicate the right and left sides facing the advancing direction of the vehicle, respectively.

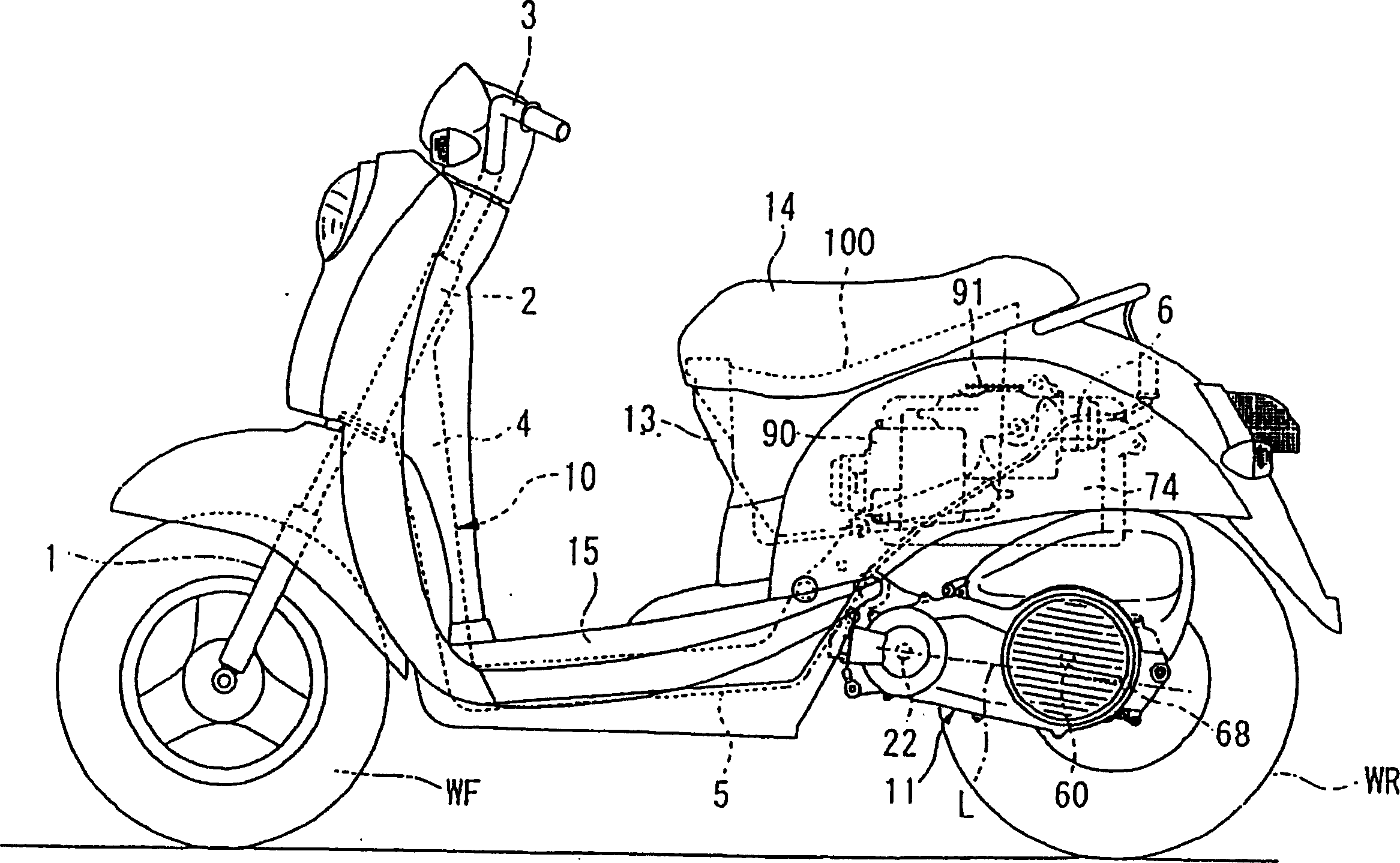

[0045] like figure 1 As shown, a hybrid vehicle according to an embodiment of the present invention is a two-wheeled integral slewing vehicle having a front fork 1 on which a front wheel WF is supported axially in front of the vehicle. The front fork 1 is pivotally installed in the head tube 2 and can be steered by operating the handle 3 . The down tube 4 extending to the rear and below is fixed on the head tube 2 . The middle bracket 5 extends horizontally from below the downcomer 4 . In addition, the rear frame 6 extends rearward and upward from the rear of the intermediate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com