Solvent recovery process for solvent method cellulose fiber preparation

A cellulose fiber, preparation process technology, applied in the direction of rayon recovery, fiber chemical characteristics, sustainable manufacturing/processing, etc., can solve the problem that colored impurities cannot be removed, morpholine and metal ions cannot be completely removed, and the solvent recovery rate can be reduced. problems, to achieve the effect of feasible process, improved fiber quality, and reduced burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

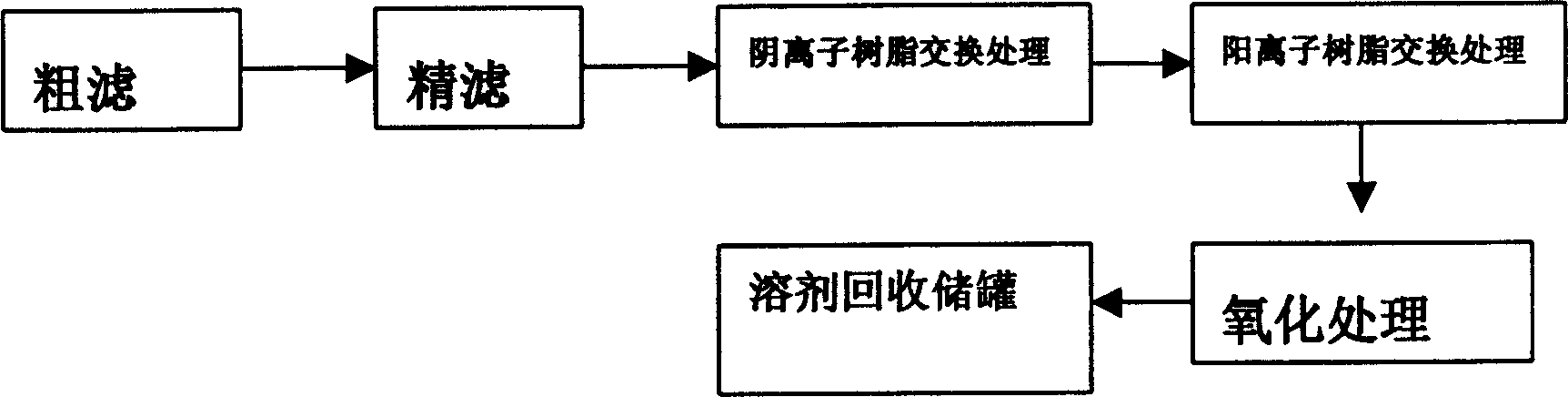

[0048] Such as figure 1 , The specific process is as follows: 1. Coarse filtration; 2. Fine filtration; 3. Anion resin exchange treatment; 4. Cationic resin exchange treatment; 5. Oxidation treatment; 6. Solvent recovery storage tank. in:

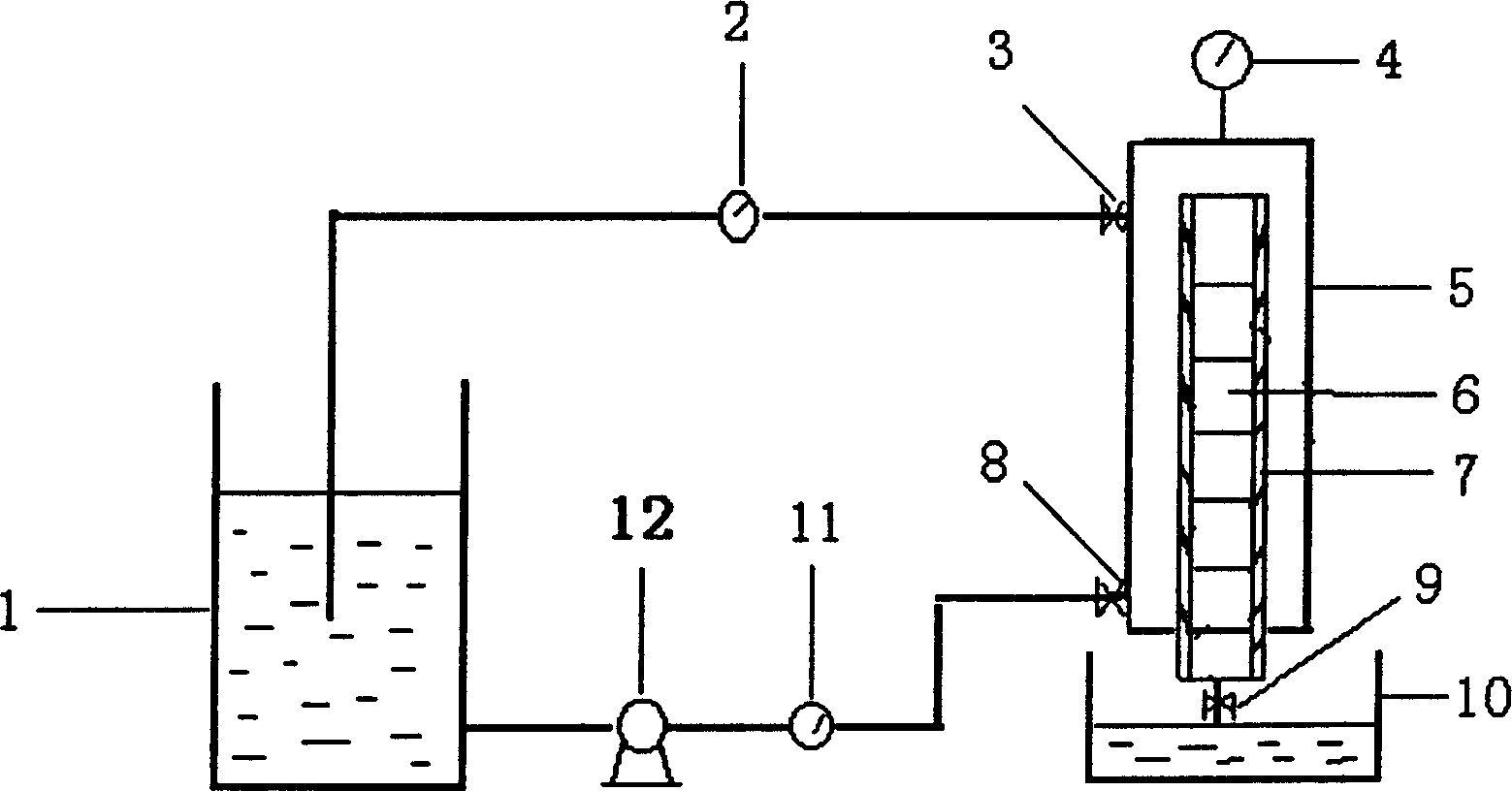

[0049] 1. Coarse filtration, the circulating waste liquid generated in production flows through a stainless steel filter column with a length of 1m and an inner diameter of 10cm at a flow rate of 10m / h. The upper, middle and lower sections of the column are respectively equipped with a filter with a height of 25cm Capacity of anthracite, pumice and gravel as filter media, the particle size is 10 ~ 20mm, 5 ~ 10mm, 2 ~ 4mm. Larger suspended solids are removed, and the crude filtrate is collected and stored in storage tank (1).

[0050] 2. Fine filtration. After coarse filtration, larger suspended impurities have been removed, but there are still smaller suspended particles in the filtrate, especially suspended particles with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com