Continuous feeder for biomass fine particle stock

A biomass and fine particle technology, applied in educts, reagents, products, etc., can solve the problems of inability to feed biomass fine particle materials, combustion of hopper materials, and poor sealing, so as to facilitate normal operation and ensure overall sealing The effect of increased performance and filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

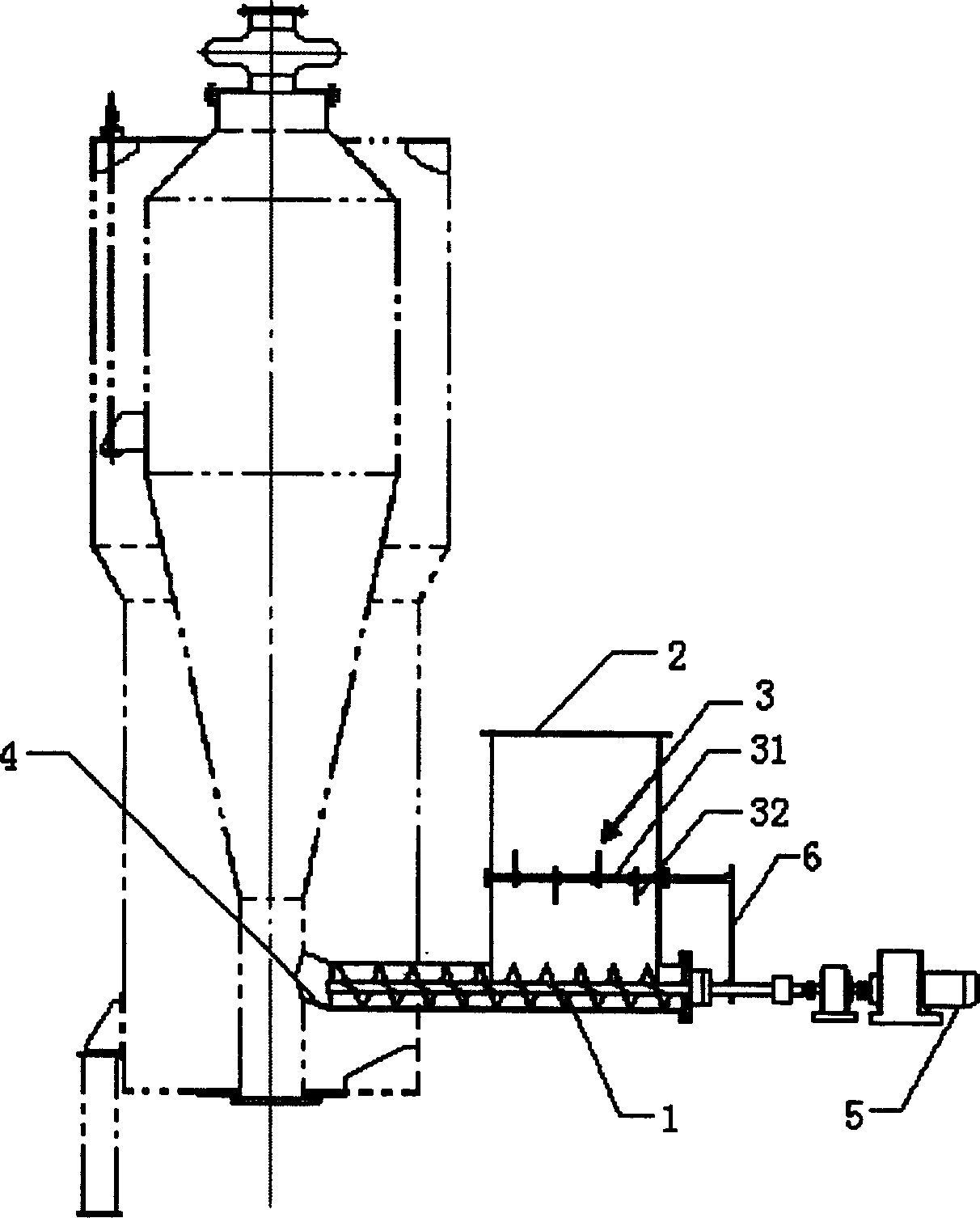

[0011] A continuous feeder for biomass fine particle materials used in a fluidized gasification furnace, consisting of a screw conveyor 1 and a hopper 2, the hopper 2 is arranged on the feeding port of the screw conveyor 1, A feeder 3 is arranged above the feed port, and a discharge transition pipe 4 is provided on the discharge port of the screw conveyor 1 and the discharge transition pipe 4 is tilted upwards. The above feeder 3 is composed of a rotating shaft 31 and a protrusion 32 , the protrusion 32 is arranged on the rotating shaft 31, and the protrusion 32 can be a convex head, a tooth, or a thin and long rod-shaped object, etc. In this embodiment, the screw rod of the screw conveyor 1 is connected to the motor 5, The rotating shaft 31 of the material pusher 3 is connected with the motor through the transmission chain 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com