Process for preparing tissue chips and apparatus thereof

A tissue chip and preparation device technology, applied in molecular biology research and new preparation fields, can solve the problems of difficulty in making high-density, high-quality tissue chips, high process cost, inconvenient positioning, etc., and is conducive to popularization. The effect of promoting, improving chip quality and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

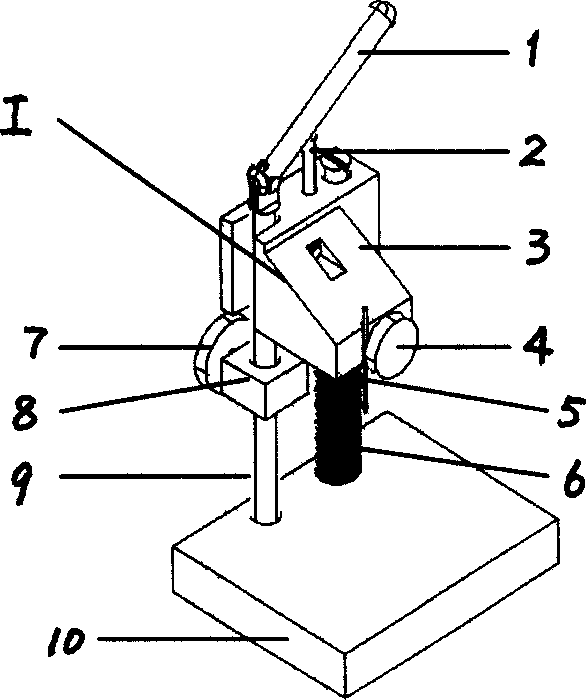

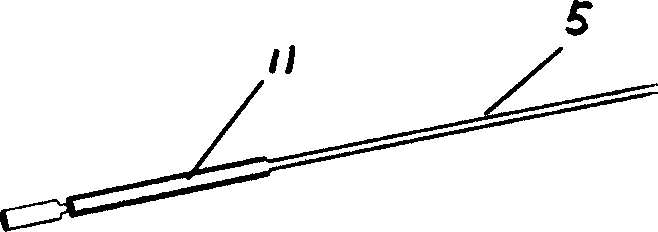

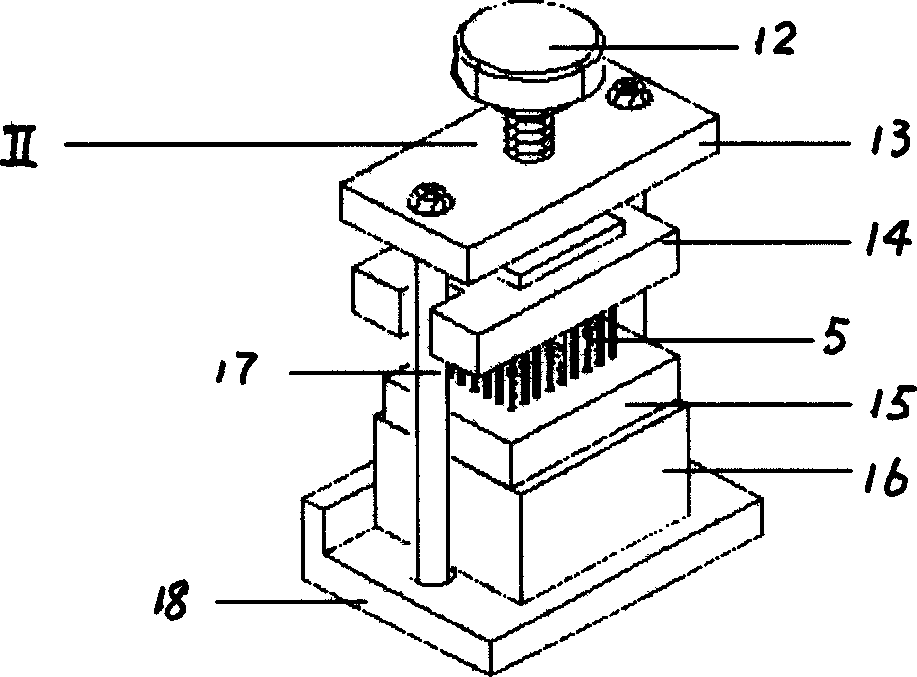

[0018] see Figure 1-Figure 5 , the tissue chip preparation device is mainly composed of a sampling instrument I and a preparation instrument II, and the sampling instrument I mainly includes a control pressure rod 1, an ejector rod 2, a guide slider 3, a fixed nut 4, a sampling needle 5 with a needle core 11, a return Position clip spring 6, positioning bolt 7, positioning block 8, guide slide bar 9, base 10, guide slide bar 9 is set on base 10, return clip spring 6 is connected with guide slide block 3, and guide slide bar 3 is provided with The fixed nut 4, the sampling needle 5 is fixed with the guide slider 3 through the fixed nut 4, the guide slider 3 is connected with one end of the ejector rod 2, the other end of the ejector rod 2 is connected with the control rod 1, and the control rod 1 is connected with the The top of the guide slider 9 is connected flexibly. When the control lever 1 is pressed down, the guide slider 3 is driven down by the ejector rod 2, and the sa...

Embodiment 2

[0023] refer to Figure 1-Figure 2 After the sample wax block is marked according to conventional techniques, the marked sample wax block is placed on the base 10 of the sampling instrument 1, the position of the positioning block 8 is fixed on the guide slide bar 9 by the positioning bolt 7, and a sampling needle 5 Fix the guide block 3 through the fixed nut 4, press down the control lever 1, and move the guide block 3 down through the ejector rod 2, so that the front end of the sampling needle 5 enters the sample wax block, and the needle core 11 will be taken The tissue sample is jacked up, and the height of the needle core 11 is equal to the height of the sample column to be taken. Release the control lever 1, and use the return compression spring 6 to lift the sampling needle 5 to complete a sampling. Figure 5 Arrange the sampled sampling needle 5 together with the lifted needle core 11 in the chip array arrangement plate 15 according to the bit sequence of the chip desi...

Embodiment 3

[0025] According to different test purposes and chip designs, chip arrays with different sampling diameters and different densities can be selected. The system can be equipped with sampling needles of various specifications (commonly used specifications are 0.6mm, 1.0mm, and 1.5mm), and they are matched with array layout plates of corresponding apertures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com