Vacuum smelting furnace

A vacuum melting furnace and melting chamber technology, applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problems of high energy consumption, complex structure, low extraction efficiency, etc., to improve production efficiency, prolong cleaning cycle, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

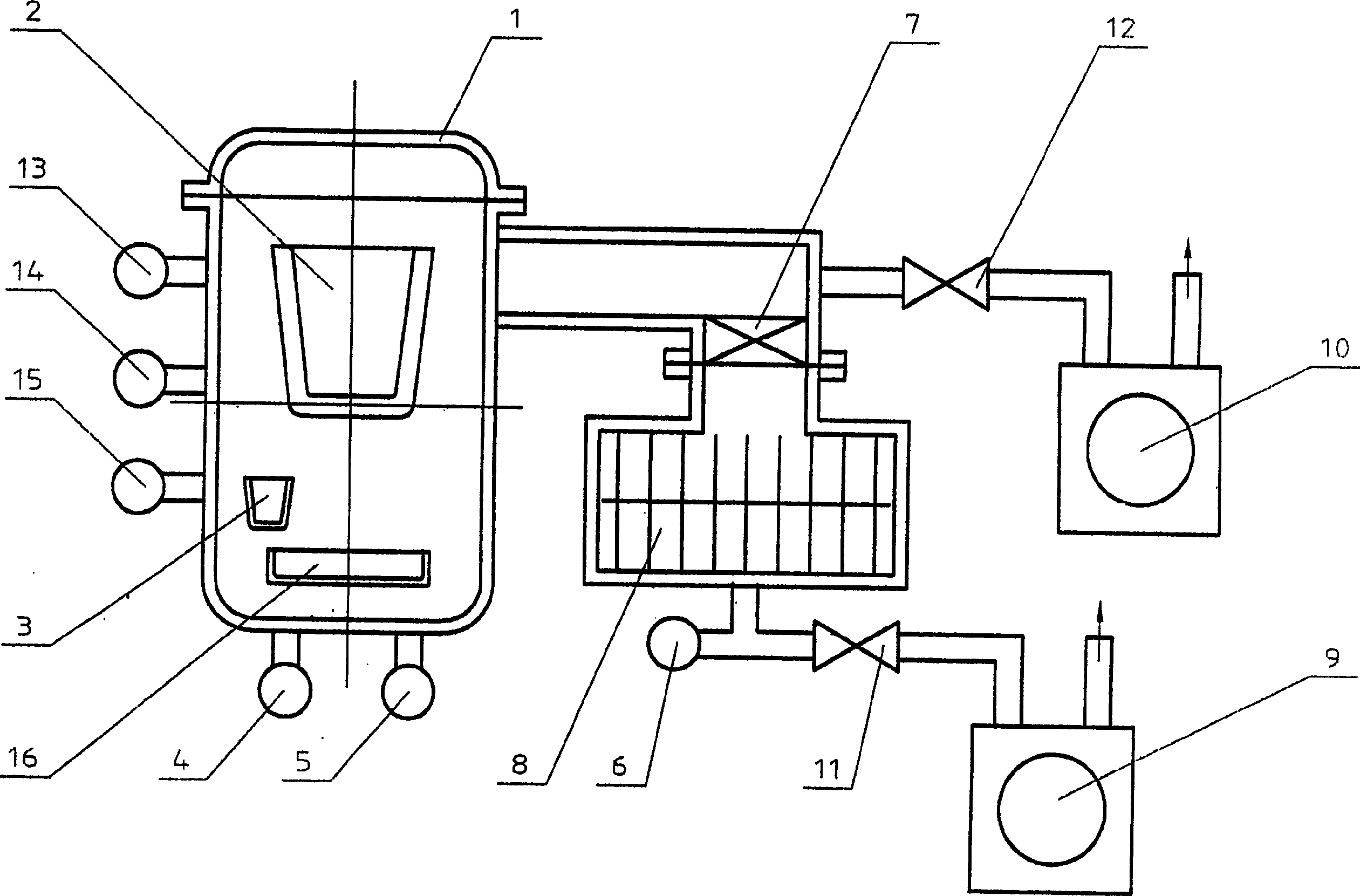

[0015] see figure 1 The vacuum melting furnace of the first embodiment of the present invention consists of a melting chamber 1, a crucible 2, an auxiliary evaporation source 3, a medium vacuum gauge 4, low vacuum gauges 5 and 6, a high vacuum valve 7, a traction molecular pump 8, and a backing vacuum pump 9 and 10, low vacuum valves 11 and 12, protective gas source 13, heating power supply 14, partial pressure monitor 15 and mold cavity 16.

[0016] Crucible 2, auxiliary evaporation source 3 and mold cavity 16 are located in melting chamber 1, medium vacuum gauge 4, low vacuum gauge 5, high vacuum valve 7, low vacuum valve 12, protective gas source 13, heating power supply 14 and partial pressure monitor 15 are respectively connected with the smelting chamber 1, the low vacuum valve 12 is also connected with the backing vacuum pump 10, the air inlet of the traction molecular pump 8 is connected with the high vacuum valve 7, the low vacuum gauge 6 and the low vacuum valve 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com