Process for preparing polycrystalline oxotitanium phthalocyanine in mixed crystal regulator

A technology of titanium phthalocyanine and regulator, applied in the direction of titanium organic compounds, etc., can solve the problems of complex process, low efficiency and long time, and achieve the effect of simple process, high efficiency and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

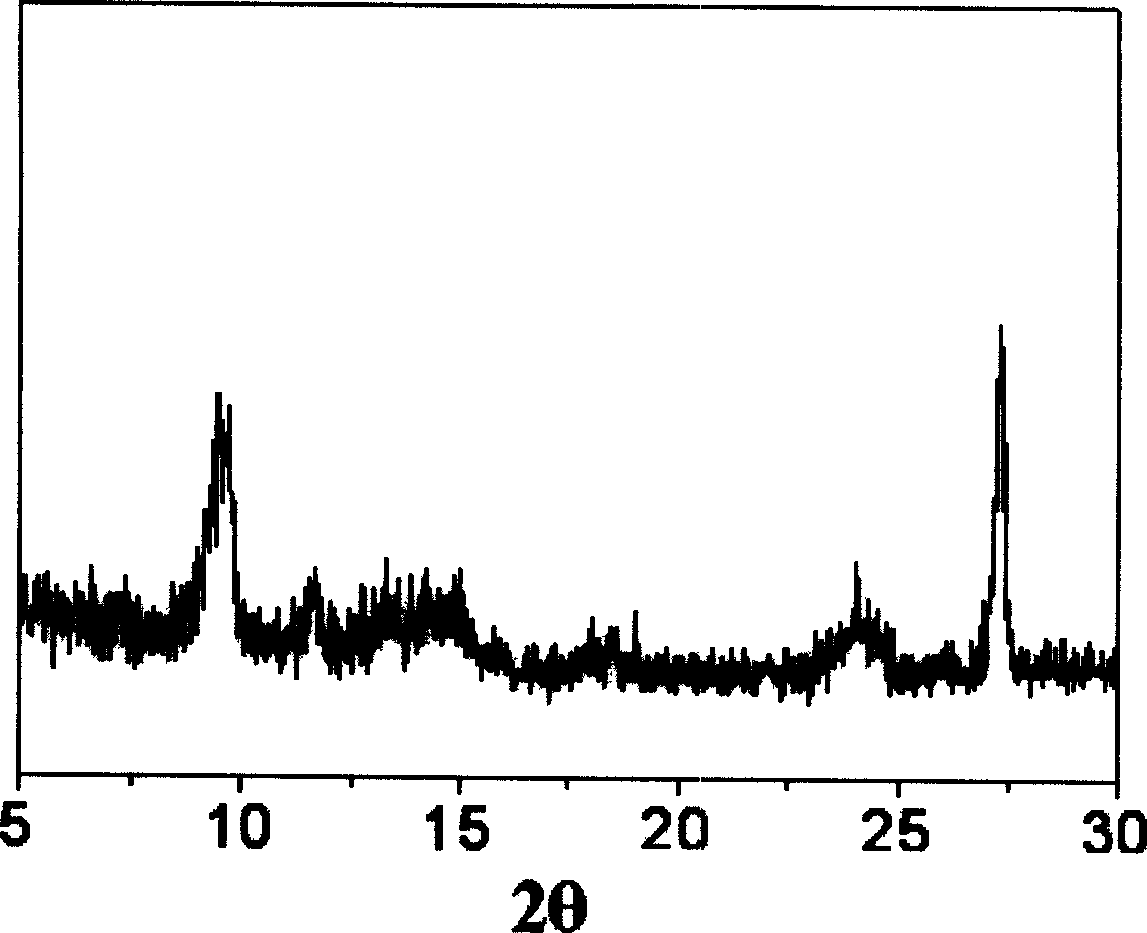

[0013] In a 250 mL three-necked flask equipped with a stirrer and a thermometer, add 90 mL of o-dichlorobenzene and 10 mL of butanol, and then add 4 g of purified titanyl phthalocyanine. Stir at room temperature for 20min, then heat to 55°C and stir for 6h. Cool to room temperature, add 100 mL of water, stir for 30 min and then filter, wash the filter cake with a large amount of methanol, and dry to obtain Y-TiOPc.

example 2

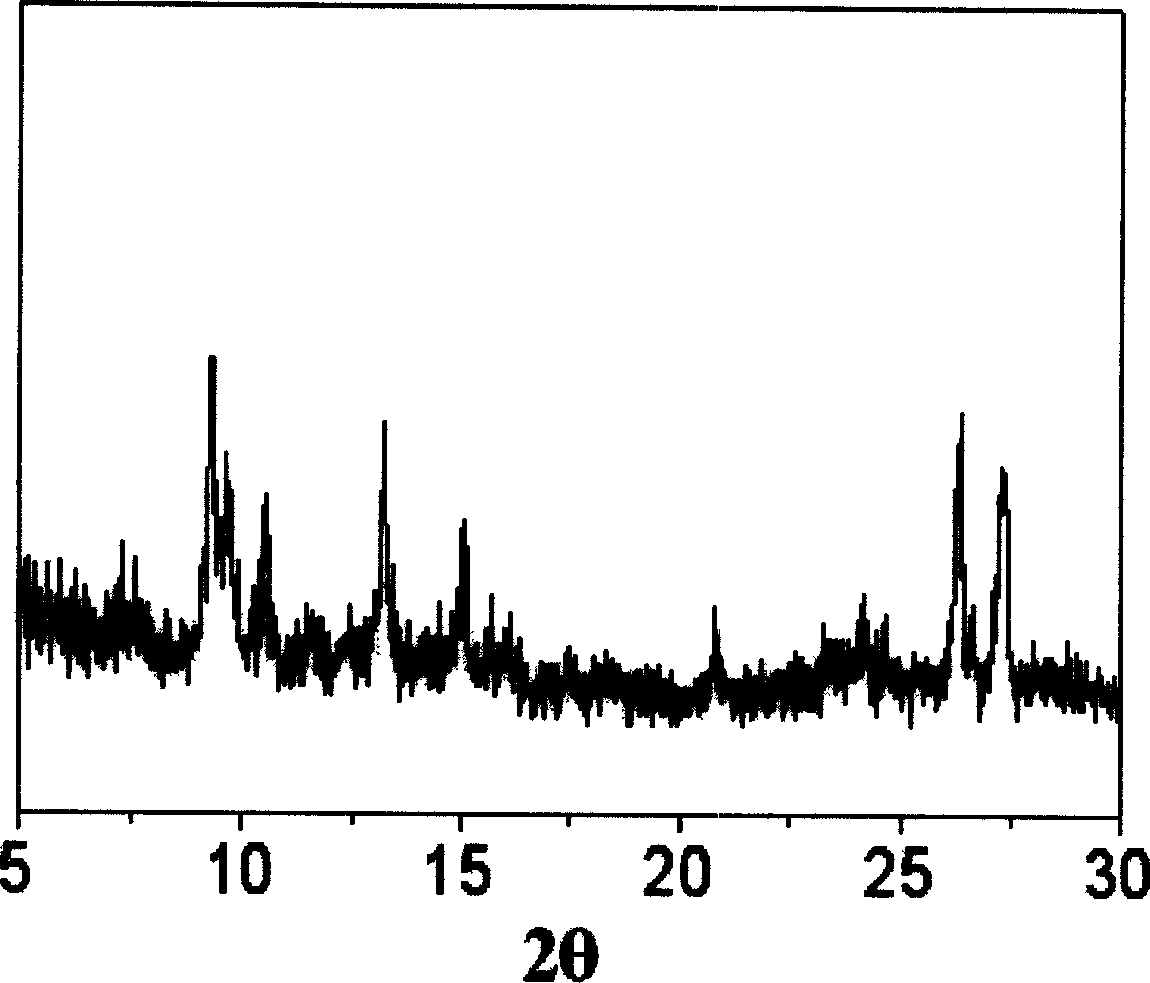

[0015] In a 250 mL three-necked flask equipped with a stirrer and a thermometer, add 60 mL of o-dichlorobenzene and 40 mL of butanol, and then add 4 g of purified titanyl phthalocyanine. Stir at room temperature for 30min, then heat to 60°C and stir for 6h. After cooling to room temperature, 120 mL of methanol was added, stirred for 30 min and then filtered. The filter cake was washed with a large amount of methanol and dried to obtain β-TiOPc.

example 3

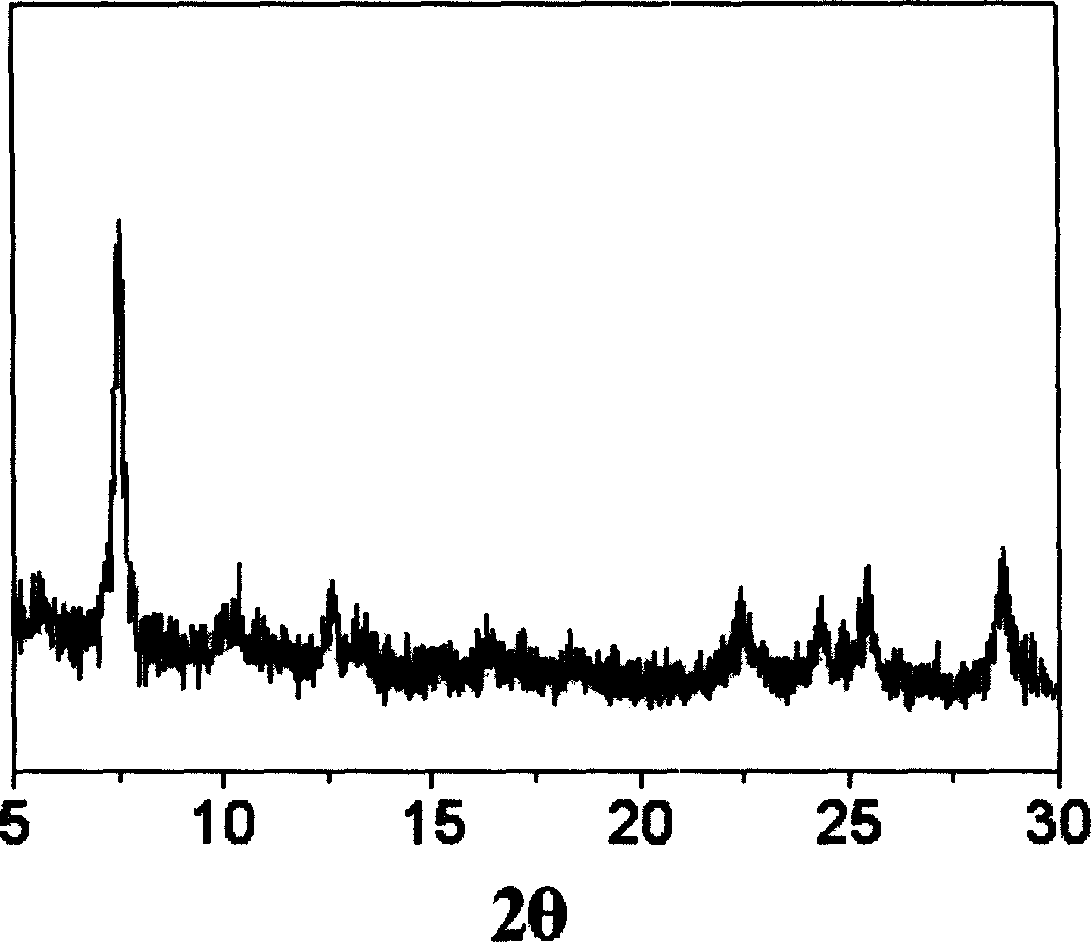

[0017] In a 250 mL three-necked flask equipped with a stirrer and a thermometer, add 20 mL of o-dichlorobenzene and 80 mL of butanol, and then add 4 g of purified titanyl phthalocyanine. Stir at room temperature for 40min, then heat to 65°C and stir for 6h. After cooling to room temperature, 150 mL of ethanol was added, stirred for 30 min and then filtered. The filter cake was washed with a large amount of methanol and dried to obtain α-TiOPc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com