Cutting machine with improved wind shaft bracket

A technology of rewinding and slitting machine, applied in the field of machinery, can solve the problems of unstable running state of the reeling shaft, decline in product quality, increase in defective products, etc., to save maintenance time and cost, reduce labor intensity, and reduce processing difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

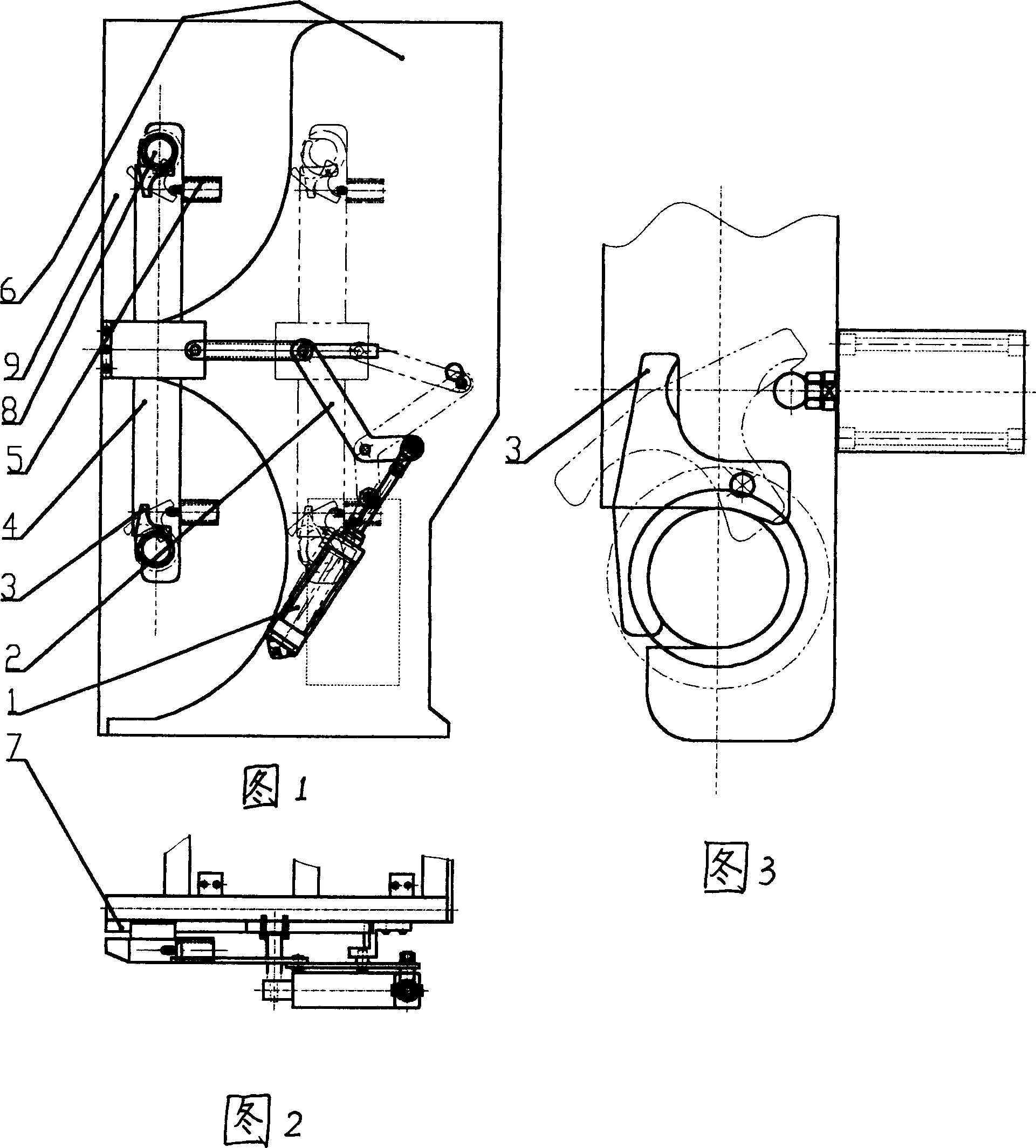

[0009] As shown in Figures 1, 2, and 3, the cylinder 1 is installed on the traction frame 6, and one end of the cylinder 1 is connected to one end of the connecting rod 2. The connecting rod 2 includes several connecting rod parts, and the combined connecting rod 2 is connected to the other end The rewinding shaft bracket 4, the rewinding shaft bracket 4 includes two brackets combined into one, and connected into one; upper translation, and the guide rail pair 7 is fixedly connected on the traction frame 6; two rewinding shafts 9 are carried at the two ends of the rewinding shaft bracket 4, and the clamping plate 3 is set here, and the clamping plate cylinder 5 is arranged on one side of the clamping plate 3 and connected with the the connection.

[0010] During work, original rewinding shaft bracket 4 does not contact with rewinding shaft 9, then connecting rod 2, rewinding shaft bracket 4 are all on the double-dot dash line position in Fig. 1; A), the cylinder 1 makes the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com