Age-hardenable, corrosion resistant ni-cr-mo alloys

An age-hardening, corrosion-resistant technology, applied in the field of wrought nickel alloys, which can solve the problems of uneven nucleation, slowness, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

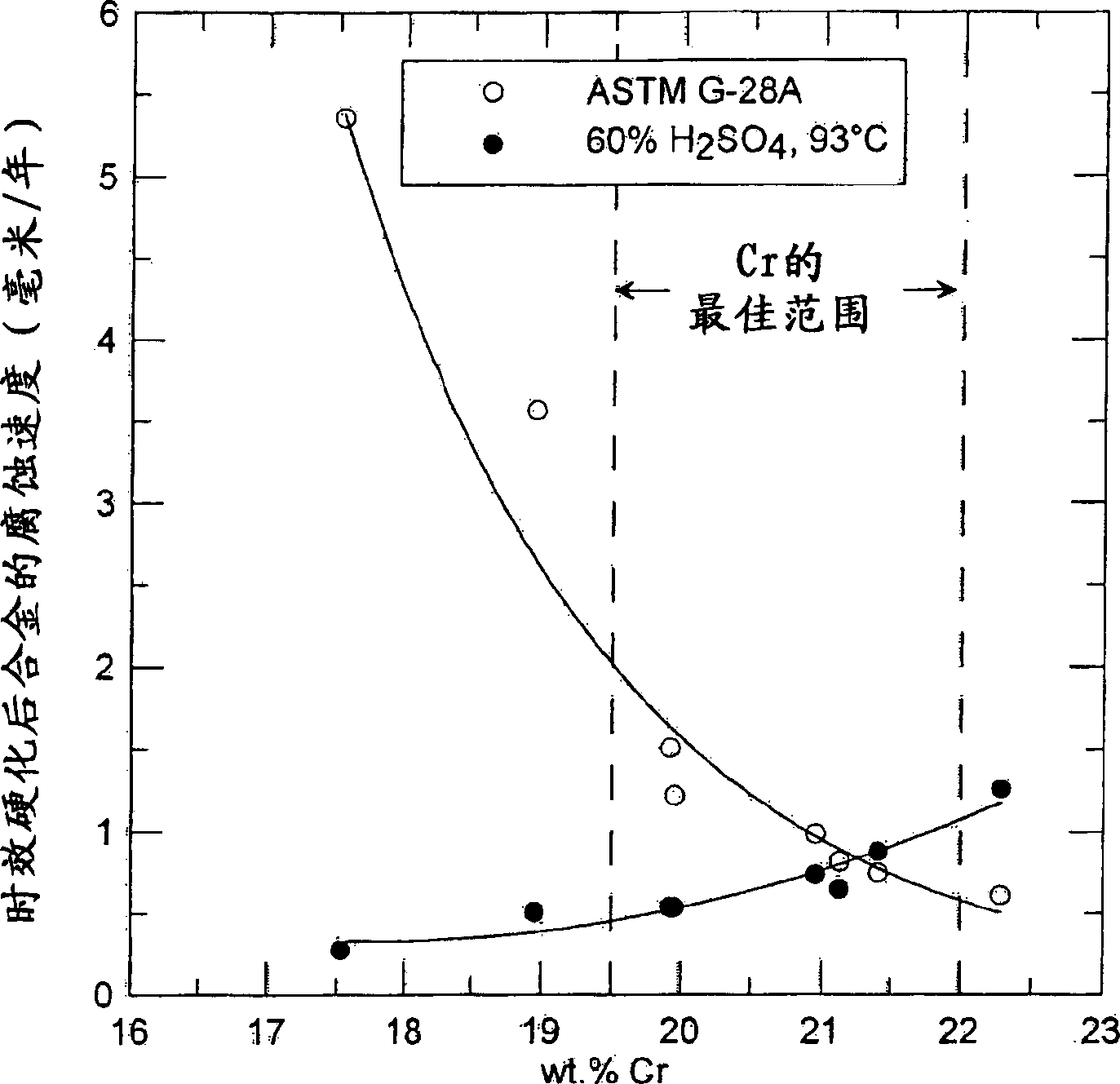

[0030] I present a Ni-Cr-Mo based alloy containing 19.5-22.0wt% Cr and 15.0-17.5% Mo which can be age hardened in 48 hours or less to produce high tensile strength while maintaining high ductility and corrosion resistance in oxidizing and reducing media. However, I have found that its overall composition should be controlled such that it has a P value between 33.5 and 35.9, where the P value is defined by the following equation:

[0031] P=2.64Al+0.19Co+0.83Cr-0.16Cu+0.39Fe+0.52Hf+0.59Mn+1.0Mo+0.68Nb+2.15Si+1.06V+0.39W+0.45Ta+1.35Ti+0.81Zr

[0032] And the element composition is given in weight percent.

[0033] A total of 18 Ni-Cr-Mo alloys were tested. Of these, 17 were experimental alloys (designated Alloy A through Alloy Q) and one was the commercial INCONEL 686 alloy. The compositions of all 18 alloys are given in Table 2 along with the calculated P values for each composition.

[0034] Table 2

[0035] The alloy compositions tested in this study

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com