Malposition type bottle cover and mould core

A mold and core technology, used in bottle/container caps, caps, household appliances, etc., can solve the problems of long mold action cycle, high production cost of bottle caps, and difficult sealing, and achieves good sealing effect. Enhanced safety and stability, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

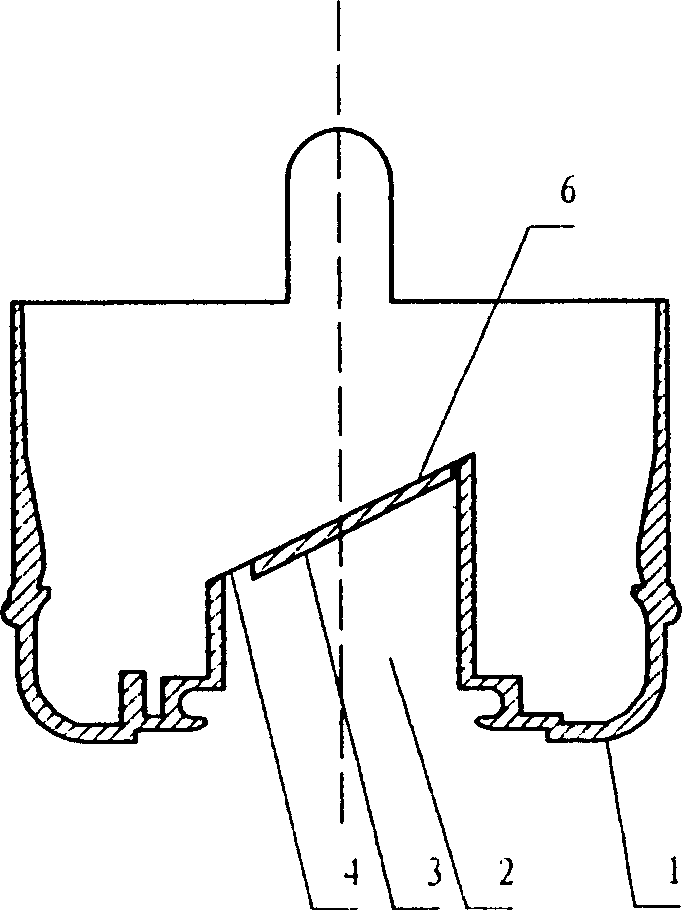

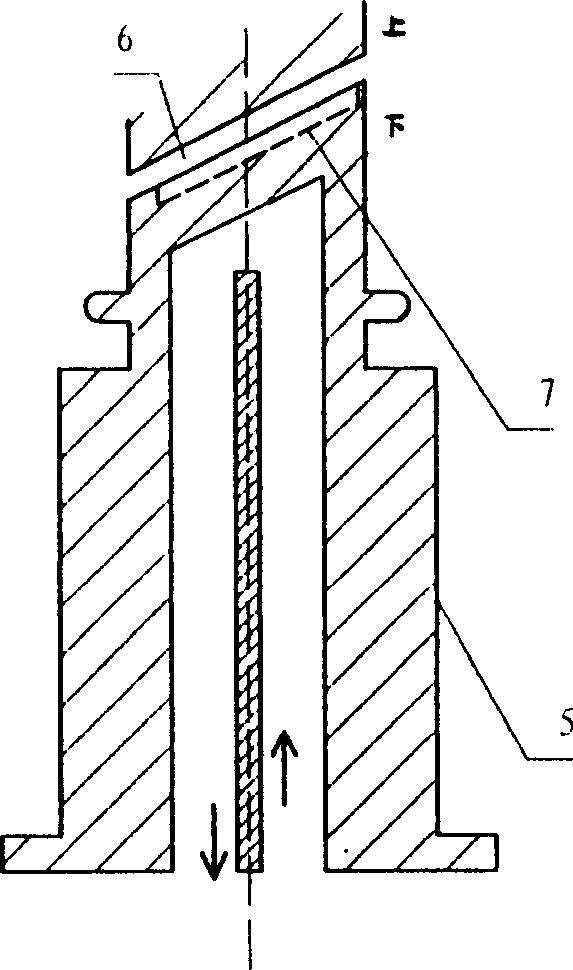

[0010] In the figure, the italic cover core (2) of the main cover (1) and the elliptical sealing chip (3) are injection molded on the mold parting surface (6) of the same oblique line, and the mutual circumferences are close to each other. The eccentric thin-walled connecting strip (4) connects the body, and the center of the elliptical sealing chip (3) is shifted to the radial direction and protrudes 0.5-3 mm into the italic cover core (2). The top of the mold core (5) is the mold parting surface (6) of the oblique ray, which is processed into a concave cavity (7) with a center offset on the parting surface, and the center of the mold core (5) has a The incoming and outgoing cooling channels and mold cores (5) are respectively fixed on the fixed plates of the upper die (injection) and the lower die (ejection).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com