Flue-cured tobacco upper smoke baking method

A curing method and flue-cured tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low reducing sugar and sugar-alkali ratio, uncoordinated internal components, and large smoking irritation, and achieve chemical composition coordination and industrial quality Fast, aftertaste comfort improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

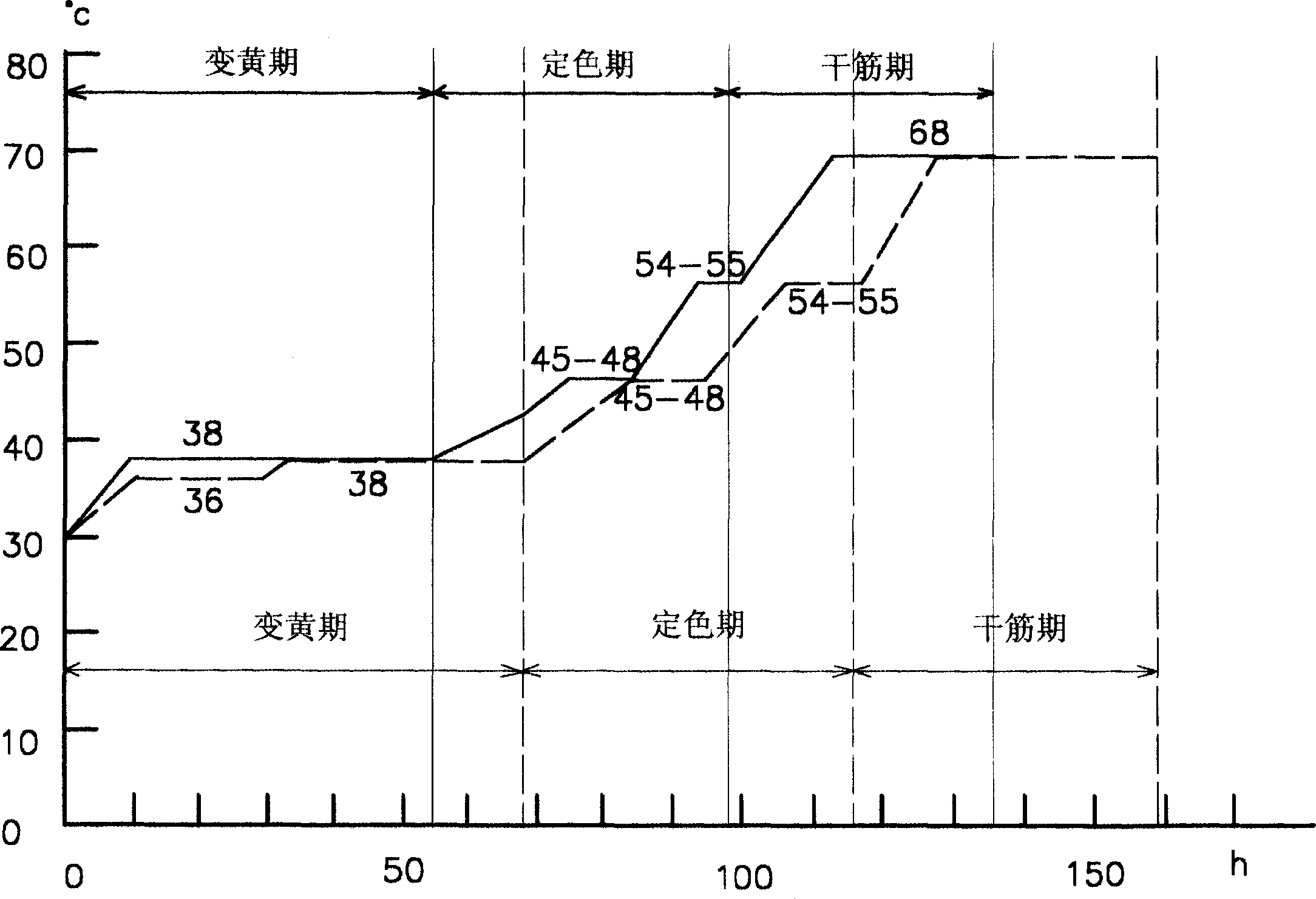

[0016] The specific implementation manners of the present invention and the principles of the technical solutions thereof will be further described in detail below. The baking temperature and humidity conditions of the present invention are improved, a new relationship between the source and the reservoir of the substance is formed, and the transformation of the substance is more suitable for industrial availability.

[0017] The upper part of the tobacco harvested by delayed harvesting and half-plant harvesting is the upper part of the tobacco leaves that are harvested after 3-5 days after the middle and lower part of the tobacco leaves are harvested. When harvesting, the stems connected to the upper part of the tobacco leaves (or the main stem) is cut together with the tobacco leaves. After the middle and lower tobacco leaves are harvested, the delayed-harvested upper tobacco leaves have sufficient light, good ventilation conditions, and better nutrition, so that the upper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com