Secondary stage prestress concrete water transport pipe and producing method

A concrete and prestressed technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as irreparable, temperature instability, voltage instability, etc., to solve corrosion resistance, enhance service life, Uniform and reliable prestress value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be further described below in conjunction with examples.

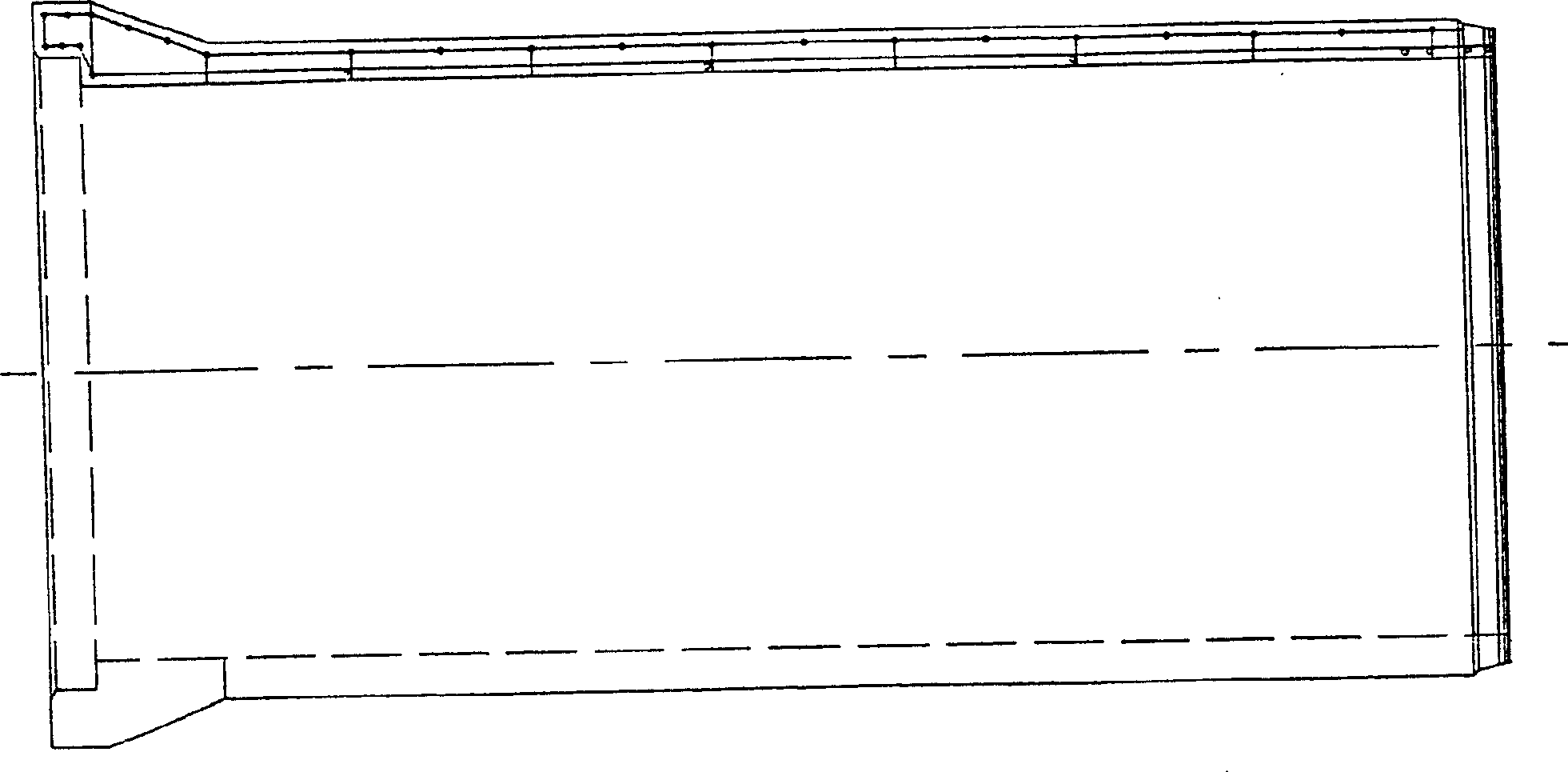

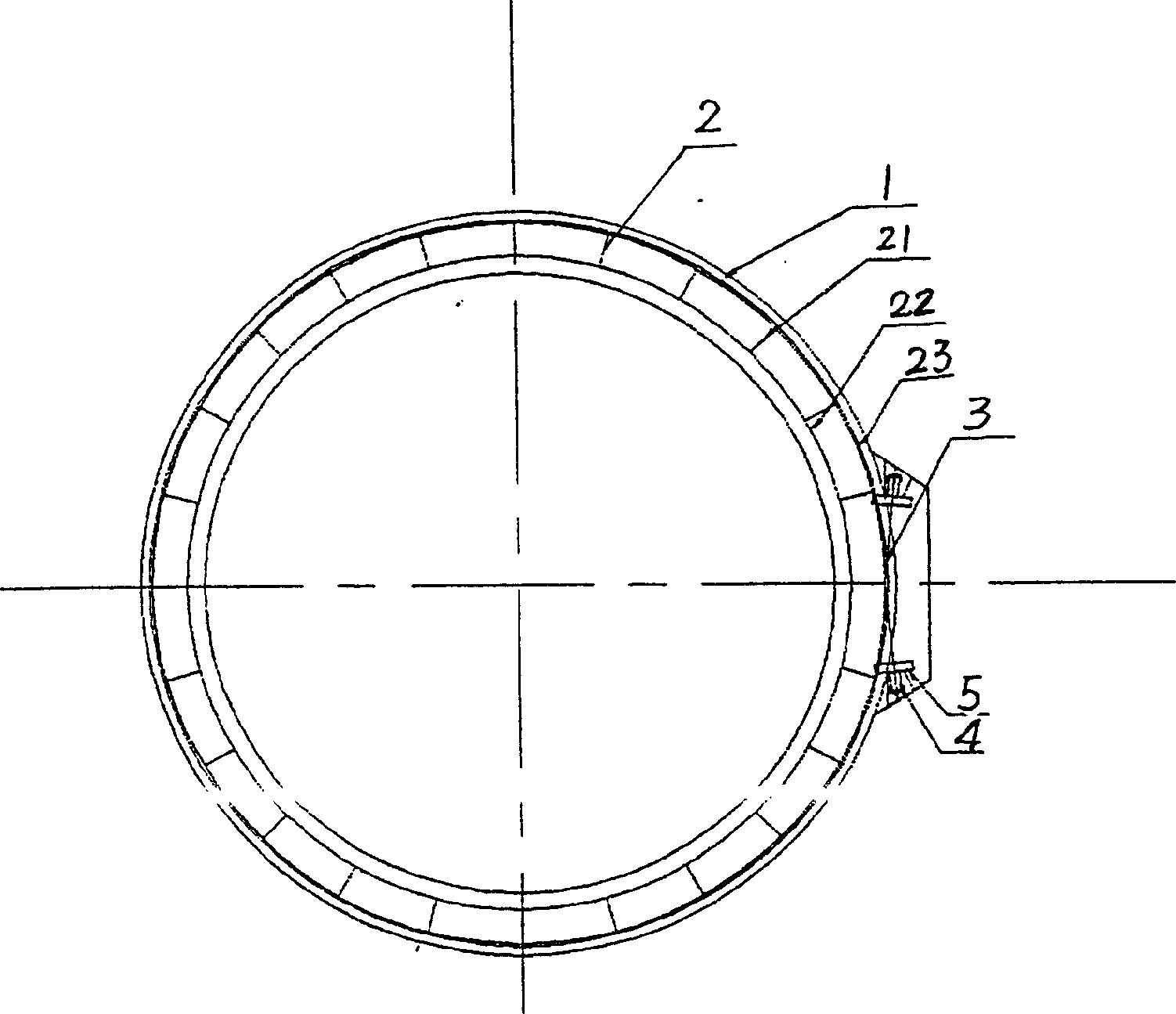

[0017] Such as figure 1 , figure 2 As shown, a two-stage prestressed concrete water pipe includes a pipe body mainly composed of a steel skeleton 2 and concrete 1, and the steel skeleton 2 includes a longitudinal reinforcement 21, an inner ring reinforcement 22 and an outer ring reinforcement 23. Steel strands 3 are arranged on the reinforcement skeleton 2 along the circumference of the reinforcement skeleton. The structure can supplement the stress value to the pipe core in the later stage of the water pipe production process, so that the stress of the pipe material can reach the required standard. Prestressed concrete water pipes usually adopt a socket connection method, one end of the pipe is a socket, and the other end is a socket.

[0018] The steel strands 3 are longitudinally segmented and arranged on the outer circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com