Tyre mould and its producing method

A technology for tire molds and manufacturing methods, which is applied in the field of molds for manufacturing rubber tires, can solve the problems of low overall mold precision, low finished product pass rate, and long production cycle, and achieves easy control of manufacturing precision, high finished product pass rate, and easy manufacturing process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

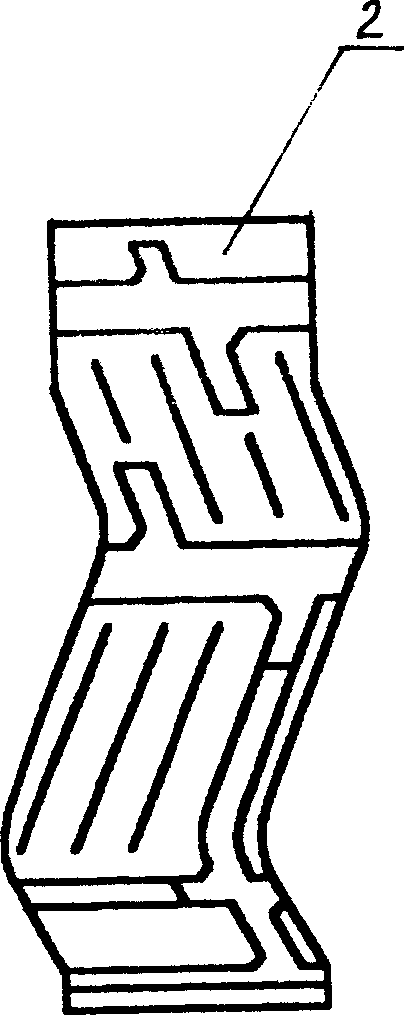

[0020] Step 1. Decompose the P unit: from the attached figure 1 with figure 2 As shown, when the tire tread is unfolded, the tread pattern can be decomposed into several P units. Each P unit 2 has different width dimensions, but the geometric shape is the same. In order to prevent the pattern steel sheet from overlapping with the dividing line, dividing line 1 Divide along the edge of the corolla;

[0021] Step 2, make P unit module: see Figure 5 As shown, the movable mold 6 of the two-half mold module is made according to the tread pattern of the P unit, and the static mold 5 matched with it. After the mold is closed, the cavity 4 is formed. The ejector top plate 7 is set on the movable mold and is made of aluminum alloy. 4 press molding in the cavity;

[0022] The made two-half mold P unit module, see image 3 with Figure 4 As shown, the thickness is 25mm, and an angle α is formed along the thickness radial direction. In order to ensure the accuracy of the combined assembly ...

Embodiment 2

[0025] In step 2 of embodiment 1, the material put into the cavity 4 is changed, and the powder metallurgy material is used for extrusion molding in the cavity, and the P unit module is obtained by sintering, and the rest repeats embodiment 1; the P unit module The thickness is controlled between 10-15mm.

Embodiment 3

[0027] Repeat step 1;

[0028] Step 2, make P unit module: see Figure 5 As shown, the movable mold 10 of the active mold module is made according to the tread pattern of the P unit, and the static mold 9 matched with it. After the mold is closed, a cavity 8 is formed. The ejector top plate 11 is set on the movable mold, and the powder metallurgy material is Extrusion molding in the cavity, after sintering, it becomes the P unit module of the active mold;

[0029] The thickness of the active mold P unit module is controlled between 10-15mm, and an angle α is formed along the thickness radial direction. In order to ensure the accuracy of the combined assembly position of the P module, a positioning slot 3 is provided at the end of the P module;

[0030] Step 3. Assembly: see Picture 9 with Picture 10 As shown, there is a segmented mold frame 18 divided into segments ①-⑨. The active mold P unit module 17 produced in step 2 is installed in the segmented mold frame 18 according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com