Rolling method for low carbon twisted steel bar

A technology of threaded steel bar and low carbon steel, applied in the field of metal rolling, can solve the problem that the strength-to-yield ratio cannot be reached, and the tensile strength of grade III steel bar cannot be fully satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

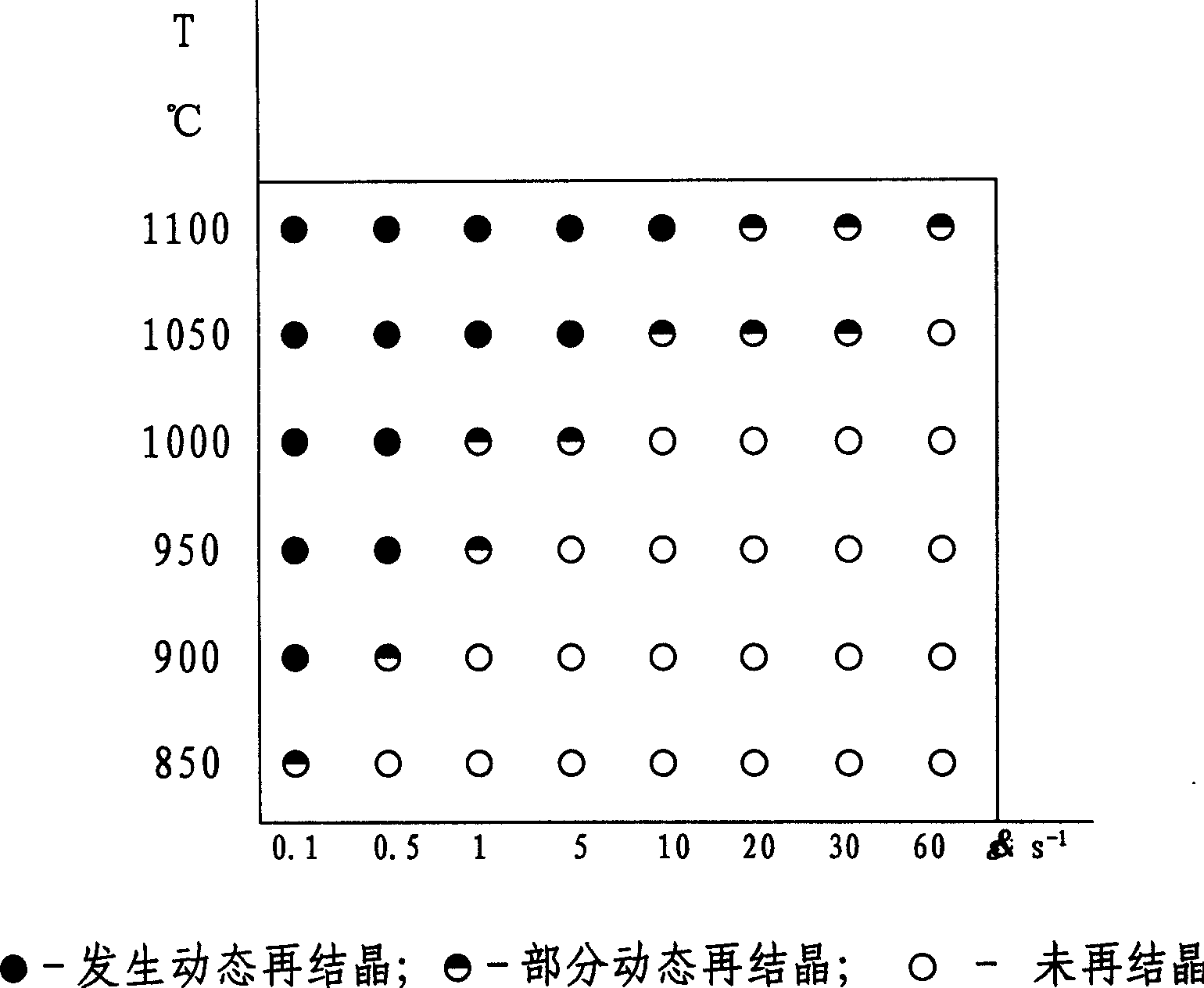

Image

Examples

Embodiment 1

[0019] The composition of the selected steel grade is 0.21%C-0.40%Si-0.79%Mn, the starting rolling temperature is 950°C, the temperature is controlled by water cooling between the intermediate and finishing rolling units and between the racks, the temperature of the finishing rolling mill is 840°C, and then the temperature is ≥10°C / The cooling rate of S is cooled to 600°C. The average yield strength obtained is σ s =460Mpa, tensile strength σ b = 630Mpa, elongation = 22.5%, strength ratio σ b / σ s =1.36, the structure is ferrite + pearlite, the ferrite grain size is 10 μm, and the pearlite grain size is 7 μm. The performance reaches the national standard of grade III steel bar.

Embodiment 2

[0021] The composition of the selected steel grade is 0.22%C-0.35%Si-0.60%Mn, the starting rolling temperature is 950°C, the temperature is controlled by water cooling between the intermediate and finishing rolling units and between the racks, the temperature of the finishing rolling mill is 850°C, and then the temperature is ≥10°C / The cooling rate of S is cooled to 550°C. The average yield strength obtained is σ s =450Mpa, tensile strength σ b = 610Mpa, elongation = 25%, strength ratio σ b / σ s =1.35, the structure is ferrite + pearlite, the ferrite grain size is 8 μm, and the pearlite grain size is 5 μm. The performance reaches the national standard of grade III steel bar.

Embodiment 3

[0023] The composition of the selected steel grade is 0.21%C-0.53%Si-0.8%Mn, the starting rolling temperature is 920°C, the temperature is controlled by water cooling between the intermediate and finishing mills and between the racks, the temperature of the finishing mill is 830°C, and then the temperature is ≥10°C / The cooling rate of S is cooled to 500°C. The average yield strength obtained is σ s =520Mpa, tensile strength σ b = 660Mpa, elongation = 22%, strength ratio σ b / σ s =1.26, the structure is ferrite + pearlite, the ferrite grain size is 7.5 μm, and the pearlite grain size is 5 μm. The performance reaches the national standard of grade IV steel bar.

[0024] batch

[0025]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com