Reinforced polyethylene pipe with super high molecular weight, manufacturing method and apparatus thereof

An ultra-high molecular weight, polyethylene pipe technology, applied in mechanical equipment, pipes/pipe joints/pipe fittings, pipes, etc., can solve the problems of poor safety and reliability, high pipe cost, high manufacturing cost, and achieve safe and reliable production and use. The effect of cost reduction and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

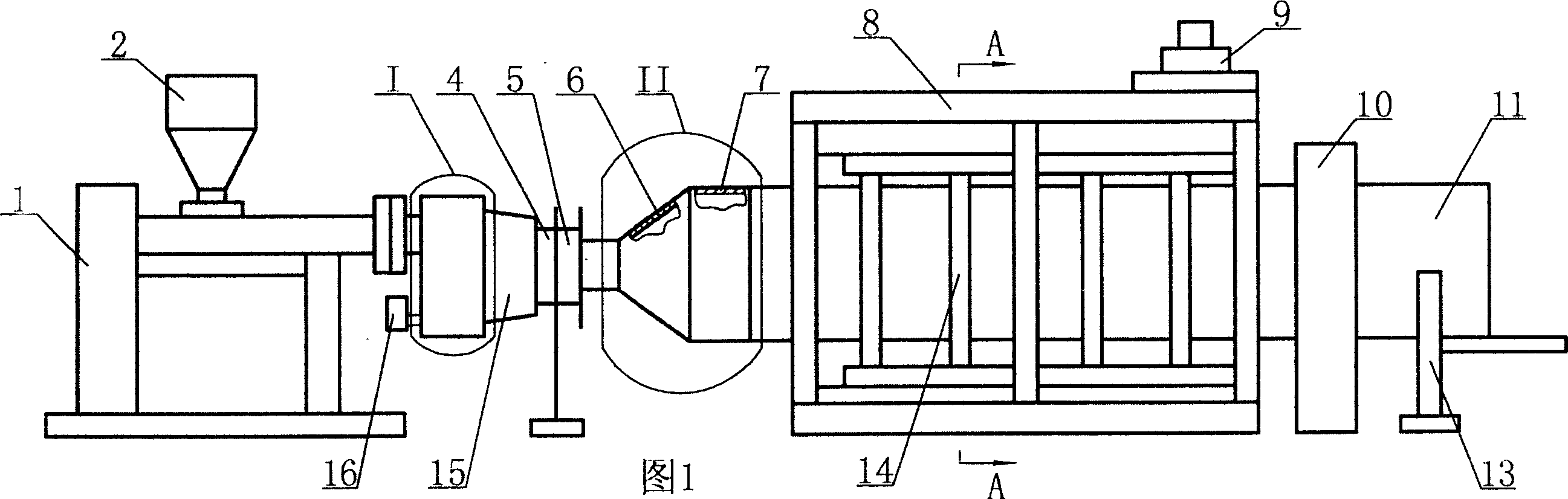

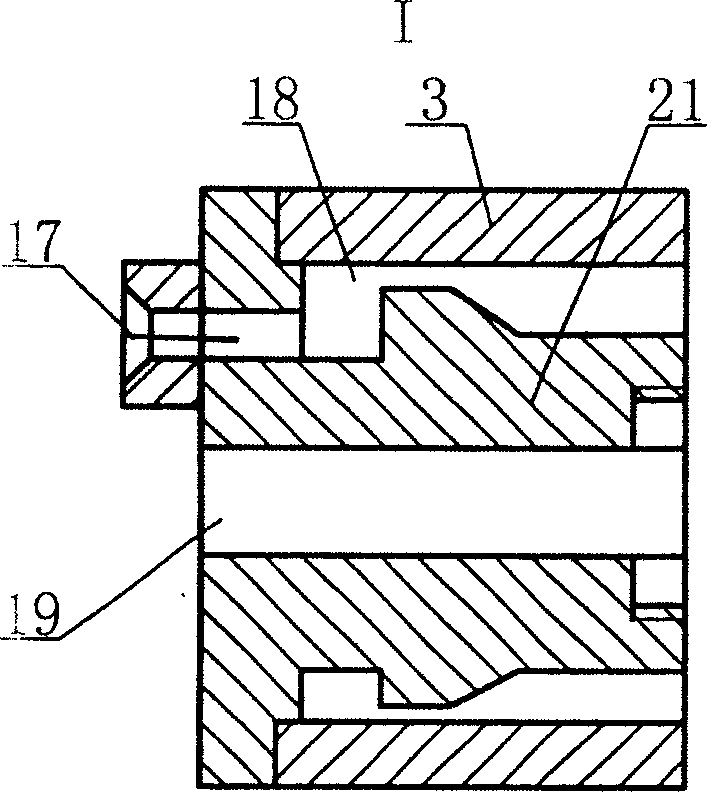

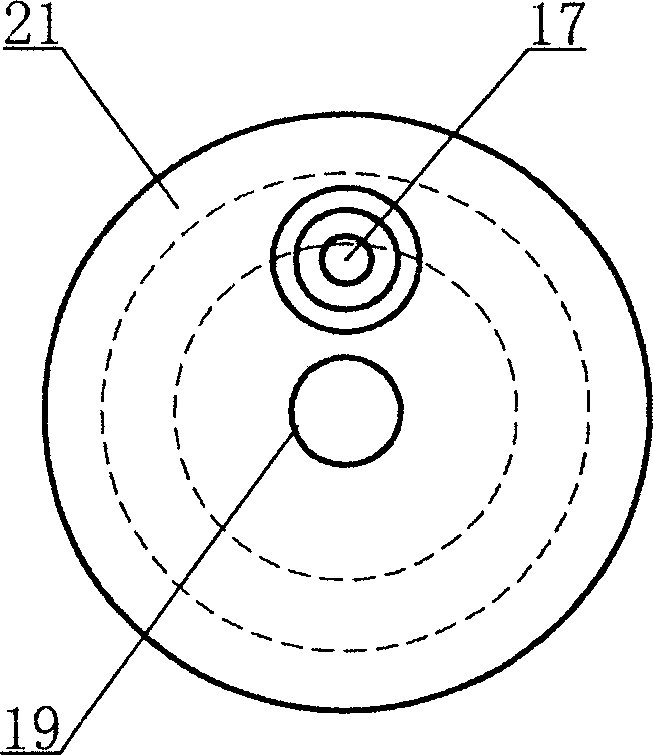

[0012] The embodiment of the present invention will be further described with reference to the accompanying drawings, and the protection scope of the technical solution of the present invention is not limited only to this embodiment.

[0013] The pipe material of the present invention needs batching at first, and the scope of the raw material mixing ratio of adopting in parts by weight is: 91-97.5 parts of ultra-high molecular weight polyethylene, 2-7 parts of polyethylene wax, 0.5-2 parts of carbon black, in this Any combination within the range, for example: take 94 parts of ultra-high molecular weight polyethylene, 5 parts of polyethylene wax, and 1 part of carbon black, or take 91.5 parts of ultra-high molecular weight polyethylene, 7 parts of polyethylene wax, 7 parts of carbon black, and carbon black 1.5 parts, or take 97.5 parts of ultra-high molecular weight polyethylene, 2 parts of polyethylene wax, and 0.5 parts of carbon black, or take 97.5 parts of ultra-high molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com