Temperature-sensitive driver of door closing apparatus

A technology of driving device and door closer, which is applied in door/window fittings, power control mechanism, wing leaf control mechanism, etc. It can solve the problems of complex system structure, failure to work, failure to use again, etc., to achieve accurate temperature response, Energy saving and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

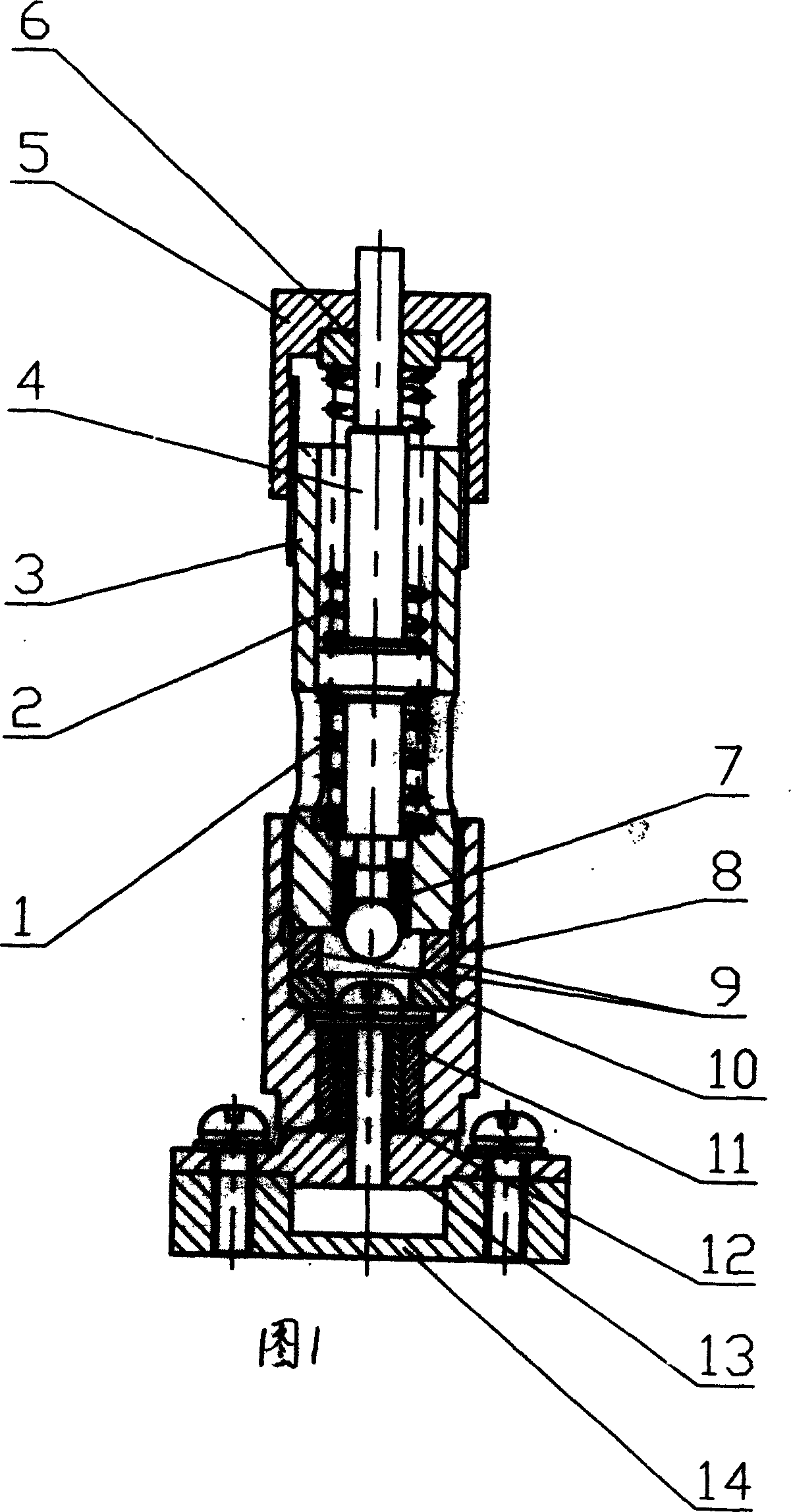

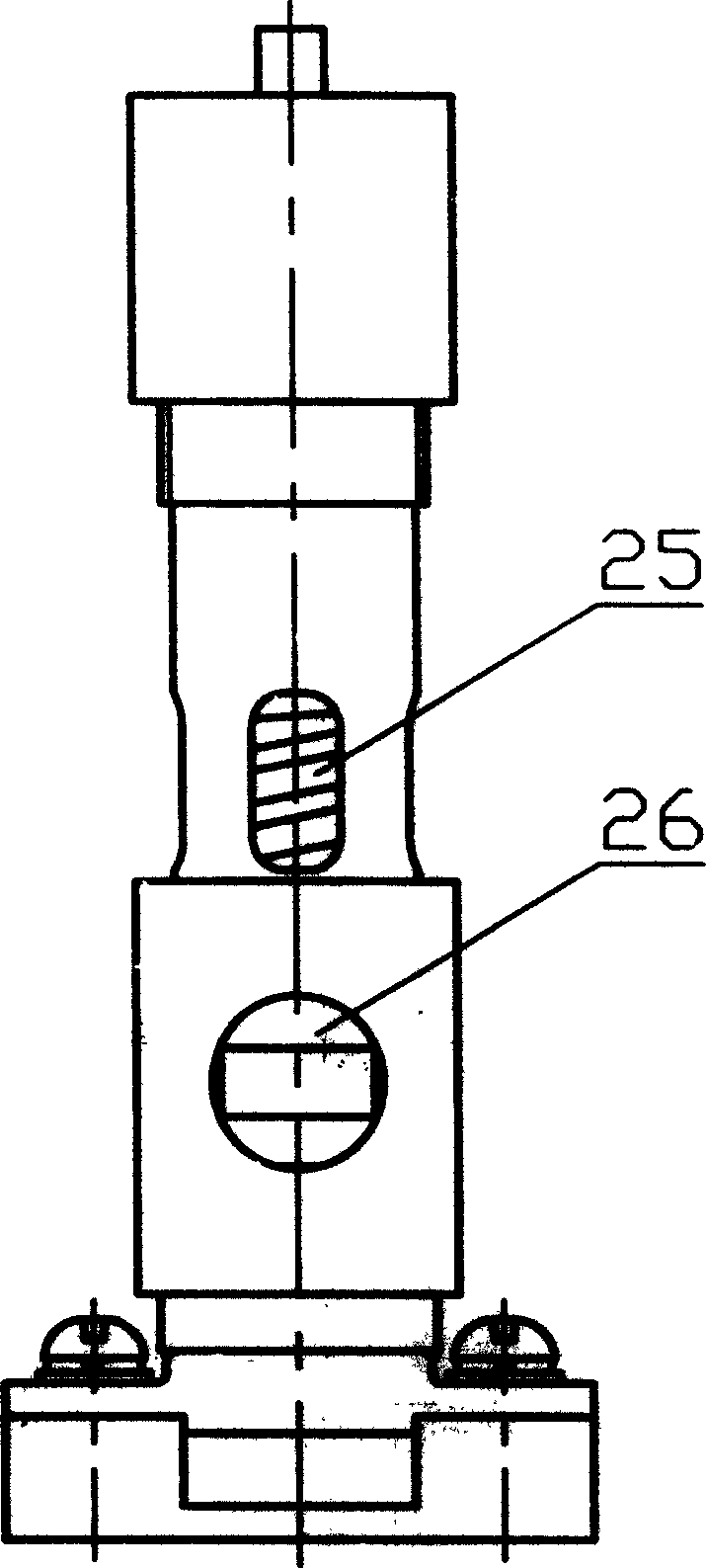

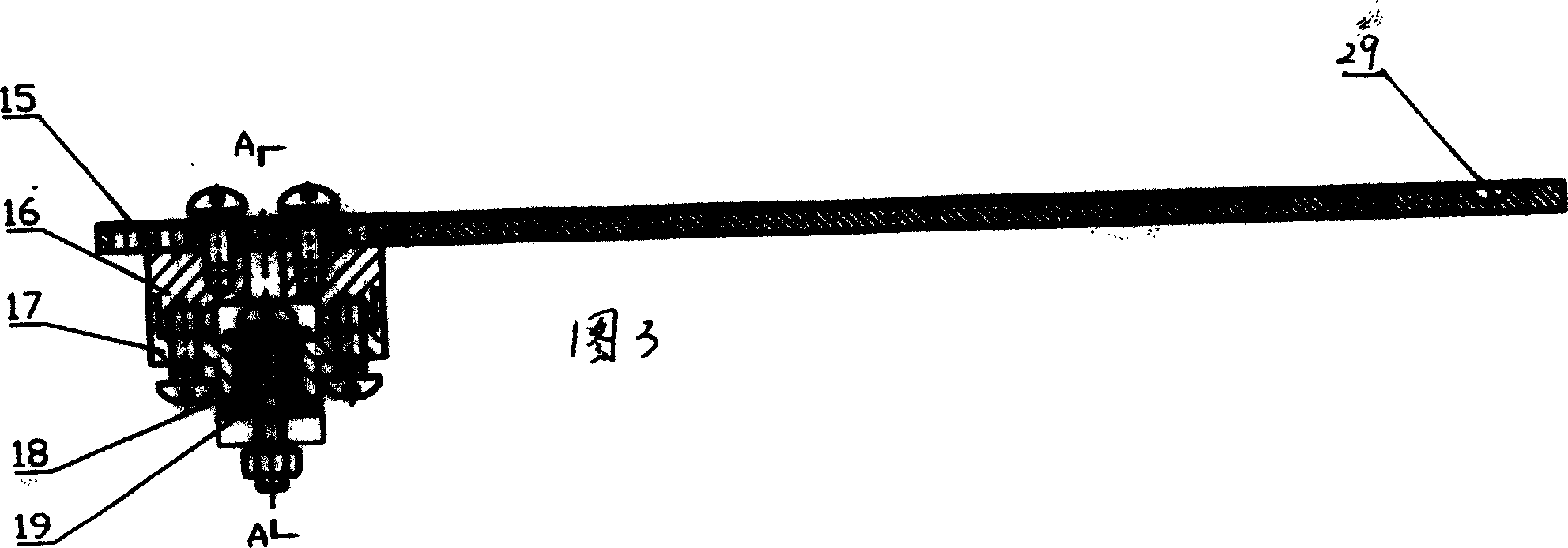

[0013] The accompanying drawings show the structure of the present invention and its embodiments, and further describe the relevant details and working principles of the embodiments in conjunction with the accompanying drawings. The temperature-sensitive driving device of the door closer has a spring sleeve 3 and a support rod 15, and a stepped push rod 4 is arranged inside the spring sleeve 3, and the stepped push rod 4 is a three-step ladder. The top of 4, that is, the first stage is provided with a bias spring 2, and the bottom of the stepped push rod 4, that is, the third stage is provided with a shape memory alloy (shape memory alloy) spring 1, and the shape memory alloy spring 1 is composed of a narrow temperature Made of wide hysteresis memory alloy, it has the characteristics of stable phase transition point, accurate and reliable temperature response, and high sensitivity. The shape memory alloy spring 1 can effectively increase the deformation displacement and increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com