Building structure and installing method for two-layer movable panel house

A technology for building structures and prefabricated houses, which is applied in residential buildings, building structures, buildings, etc., can solve the problems of poor wind resistance and earthquake resistance, large material loss of building prefabricated houses, and low reuse rate. Strong wind and earthquake resistance, optimized quality and economic benefits, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

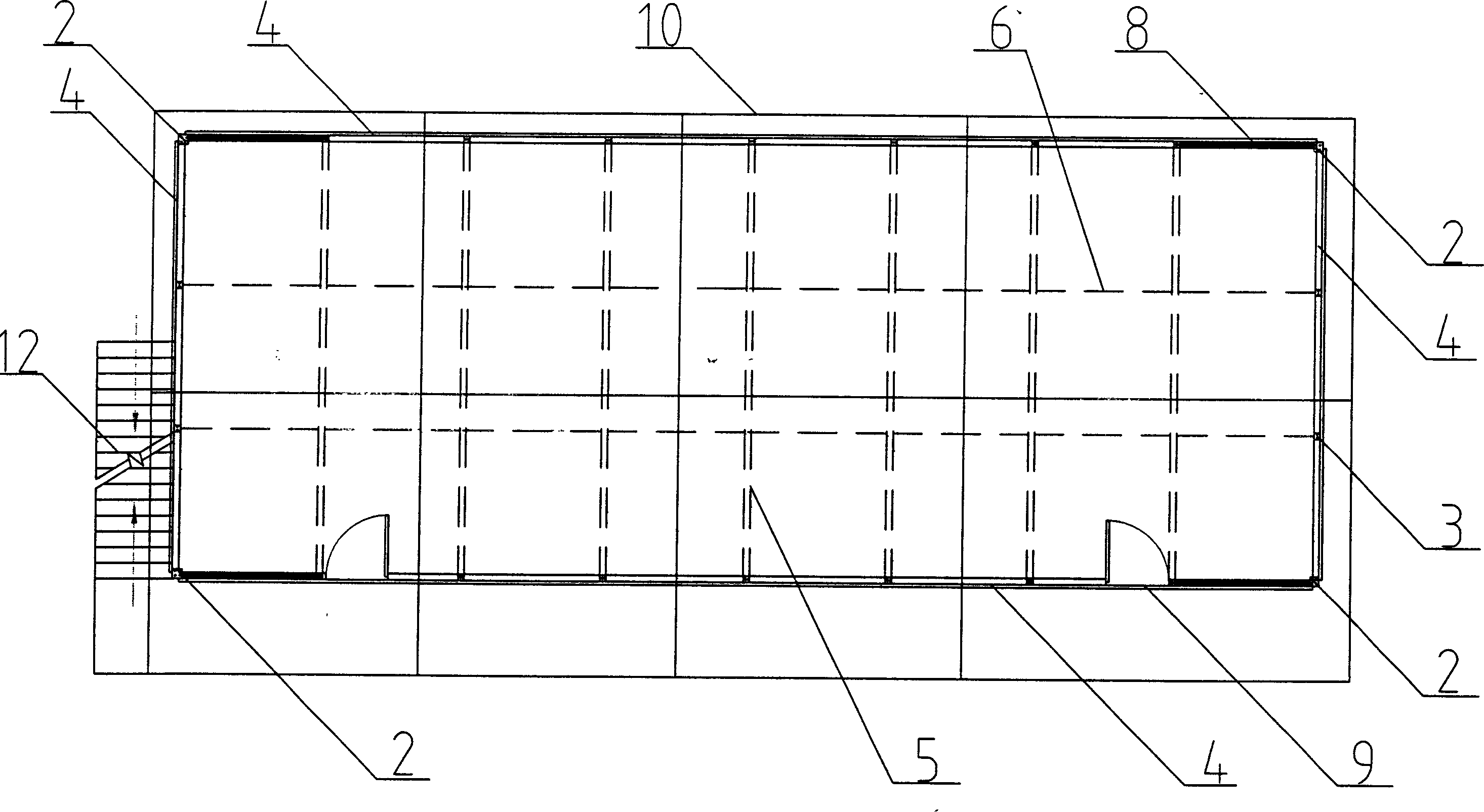

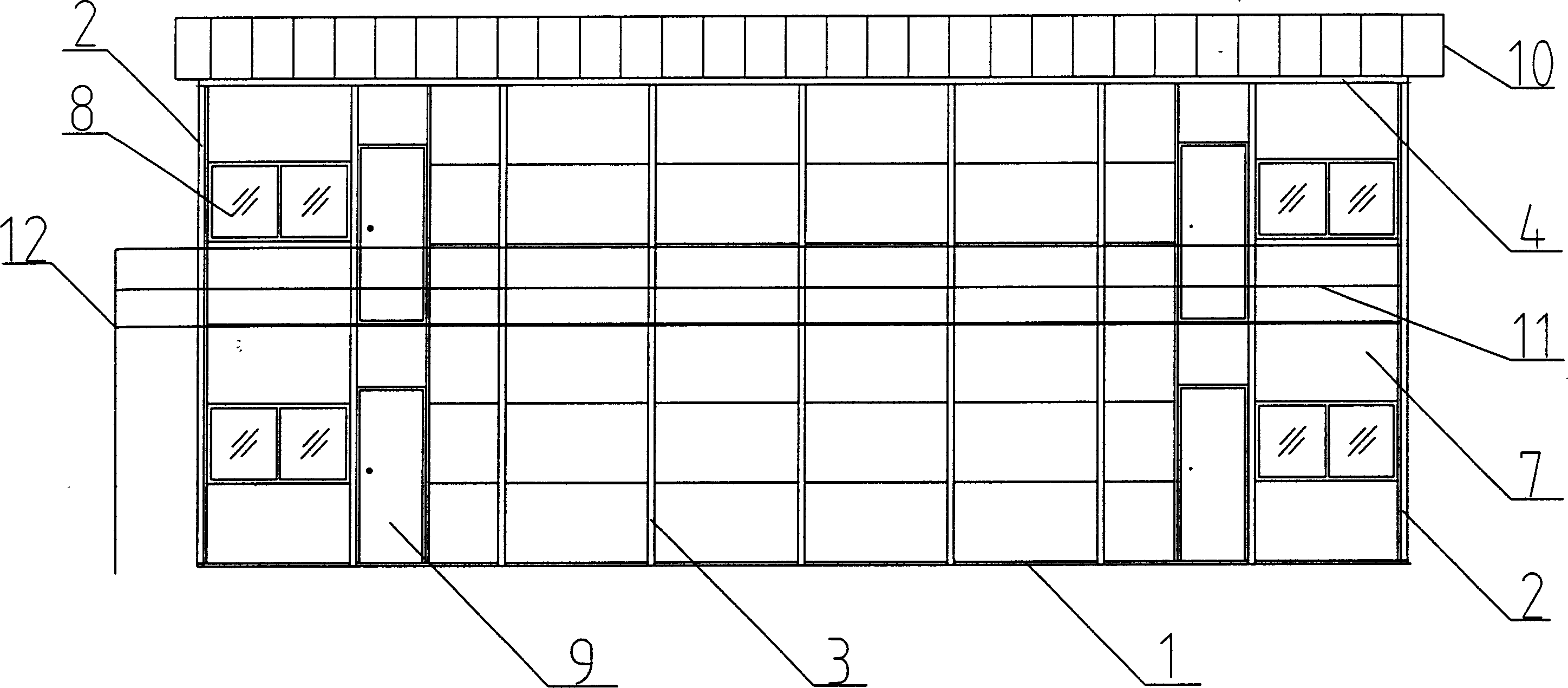

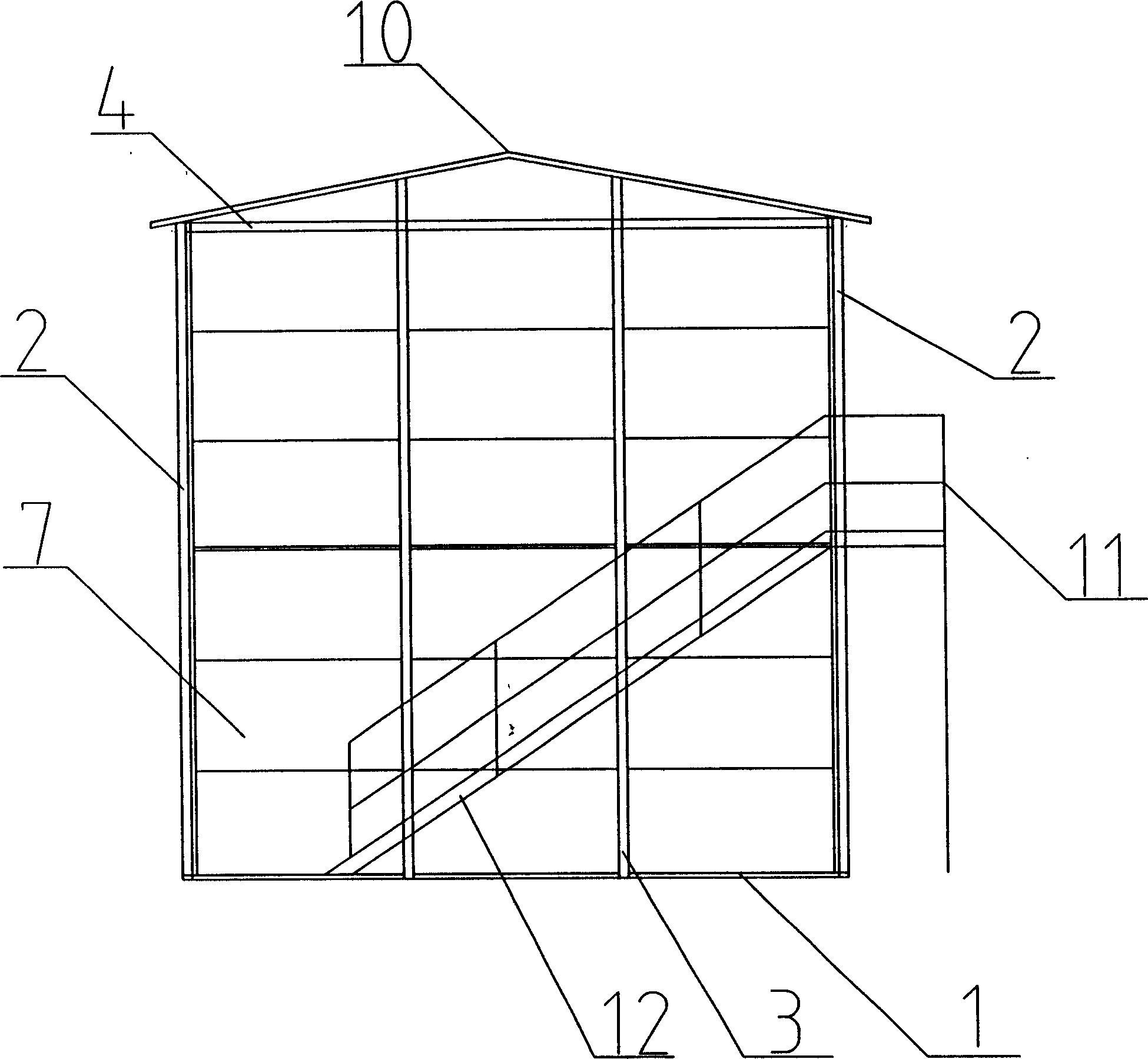

[0016] Example 1. All components of the building structure of the two-story prefabricated house of the present invention are fabricated, processed, constructed and installed using general standard modules, and all steel structural components are assembled by bolt connections. The common standard modulus of the building structure of the two-story prefabricated house is based on the central axis distance between the adjacent corner column (2) and the column (3) or between the column (3) and the column (3) as one The unit represents the symbol "K", 1K=1.82 meters. 1K is also equal to the length of a sandwich panel (7). The building structure of the two-story prefabricated house usually takes "2K" as a standard bay, and can be assembled with any number of units "K" that are required in the longitudinal direction. The span of the two-story prefabricated house building structure also takes "K" as the unit, and the maximum span can be made into five units of "K". However, the draw...

Embodiment 2

[0017] Example 2. The actual construction method steps of the two-story prefabricated house building structure of the present invention are:

[0018] 1. Connect the four ground beams (1) with bolts at right angles to form a rectangular ground beam (1) frame, and fix the ground beam (1) frame on the ground;

[0019] 2. Connect the four corner columns (2) with vertical bolts at the four right-angle positions of the frame of the ground beam (1);

[0020] 3. On the frame of the ground beam (1), connect several upright columns (3) with vertical bolts according to the length distance (1.82 meters) of 1K;

[0021] 4. Connect each joist (5) with the opposite corner column (2) or column (3) into right-angle bolts, weld several purlin seats on each joist (5), and several purlins (6 ) is connected by bolts at right angles to the joist (5) through the purlin seat.

[0022] 5. Connect the four ring beams (4) with right angle bolts to form a rectangular ring beam (4) frame;

[0023] 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length dimension | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com