Glass fiber silk screen tape commutating conducting wire, and its manufacture and use method

A technology of glass fiber filaments and transposed wires, which is applied in the direction of quartz/glass/glass enamel, conductors, insulated conductors, etc., and can solve problems such as disappearance and dissolution of polyester materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described below in conjunction with some preferred embodiments. It should be noted that these preferred embodiments are not limiting.

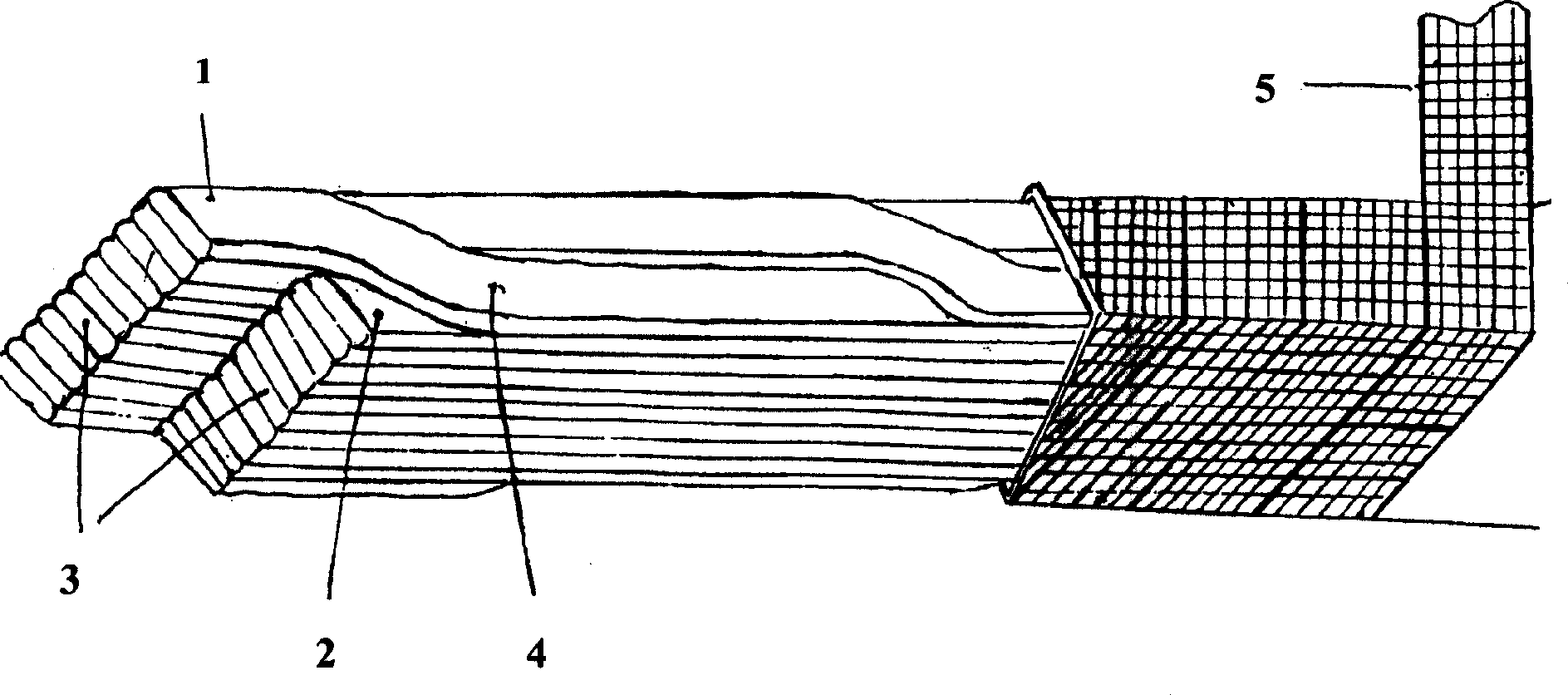

[0023] see first figure 1 , which schematically represents a perspective view of the structure of the transposed wire of the present invention; in a preferred embodiment of the present invention, a transposed wire for a transformer is provided, including a first row of enameled wire 1 and a second Rows of enamelled wires 2, each row of the first and second row of enameled wires includes several enameled wires 3, each of the first row of enameled wires 1 passes through the second row of enamelled wires through a bend 4 Conductors, each of the enameled conductors 2 of the second row passes through the enamelled conductors 1 of the first row through another bend 4, thereby realizing the transposition of the enamelled conductors 1 of the first row and the enameled conductors 2 of the second row , wherein the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com