Chemical Modifying method of filter paper core for oil-water separating filter

A technology of chemical modification and oil-water separation, applied in separation methods, chemical instruments and methods, filter paper, etc., can solve problems such as diesel engine failure and damage to internal components, and achieve the effects of low price, simple method and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

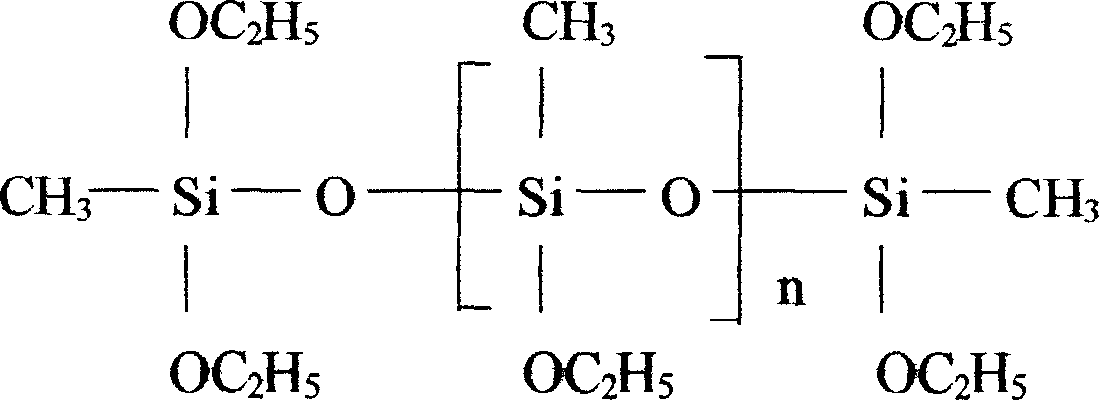

[0036] A. Silicone glass resin 6 # or 7 # , the total dry weight is 100 parts;

[0037] B. γ-glycidyloxypropyltrimethoxysilane, referred to as KH560, the content is 4 parts;

[0038] C. A+B is prepared into an alcohol solution containing 18% by dry weight of A with absolute alcohol.

Embodiment 2

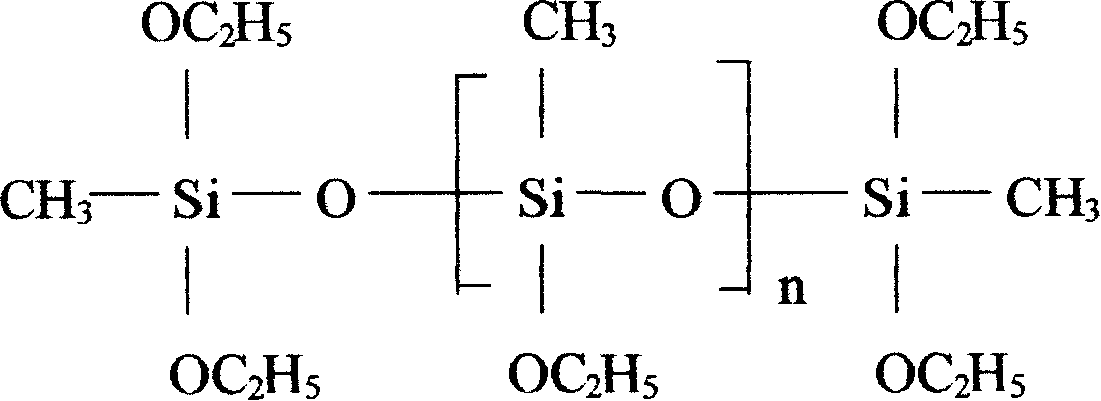

[0040] A, methyl silicone resin, trade name SAR5, total dry weight is 100 parts;

[0041] B. γ-Aminopropyltriethoxysilane, referred to as KH550, the content is 2 parts;

[0042] C. A+B is prepared into an alcohol solution containing 12% by dry weight of A with absolute alcohol.

Embodiment 3

[0044] A. Silicone glass resin 6 # or 7 # , the total dry weight is 100 parts;

[0045] B. γ-Aminopropyltriethoxysilane, referred to as KH550, the content is 4 parts;

[0046] C. A+B is prepared into an alcoholic solution containing 15% of dry weight of A with absolute alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com