Special spray ink stabilizing agent for high speed water-brushing overshot duct

A technology for printing presses and stabilizers, which is applied in the field of special spray ink stabilizers for ink fountains of high-speed water-rubbed gravure printing presses, can solve the problems of small ink volume, damaged ink liquid-to-solid ratio, and difficult ink cleaning, etc. Aging and gelation, good printability, the effect of maintaining printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

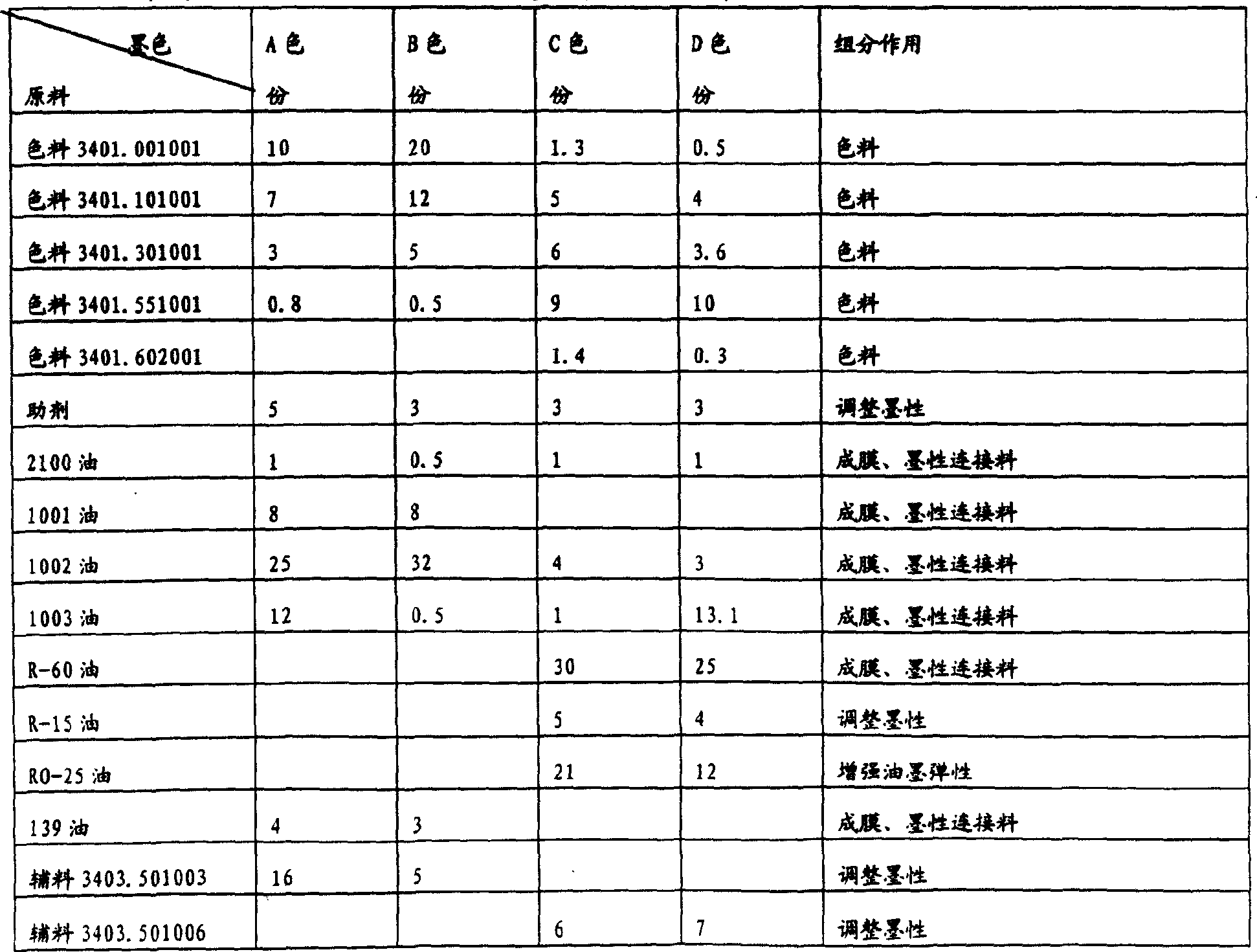

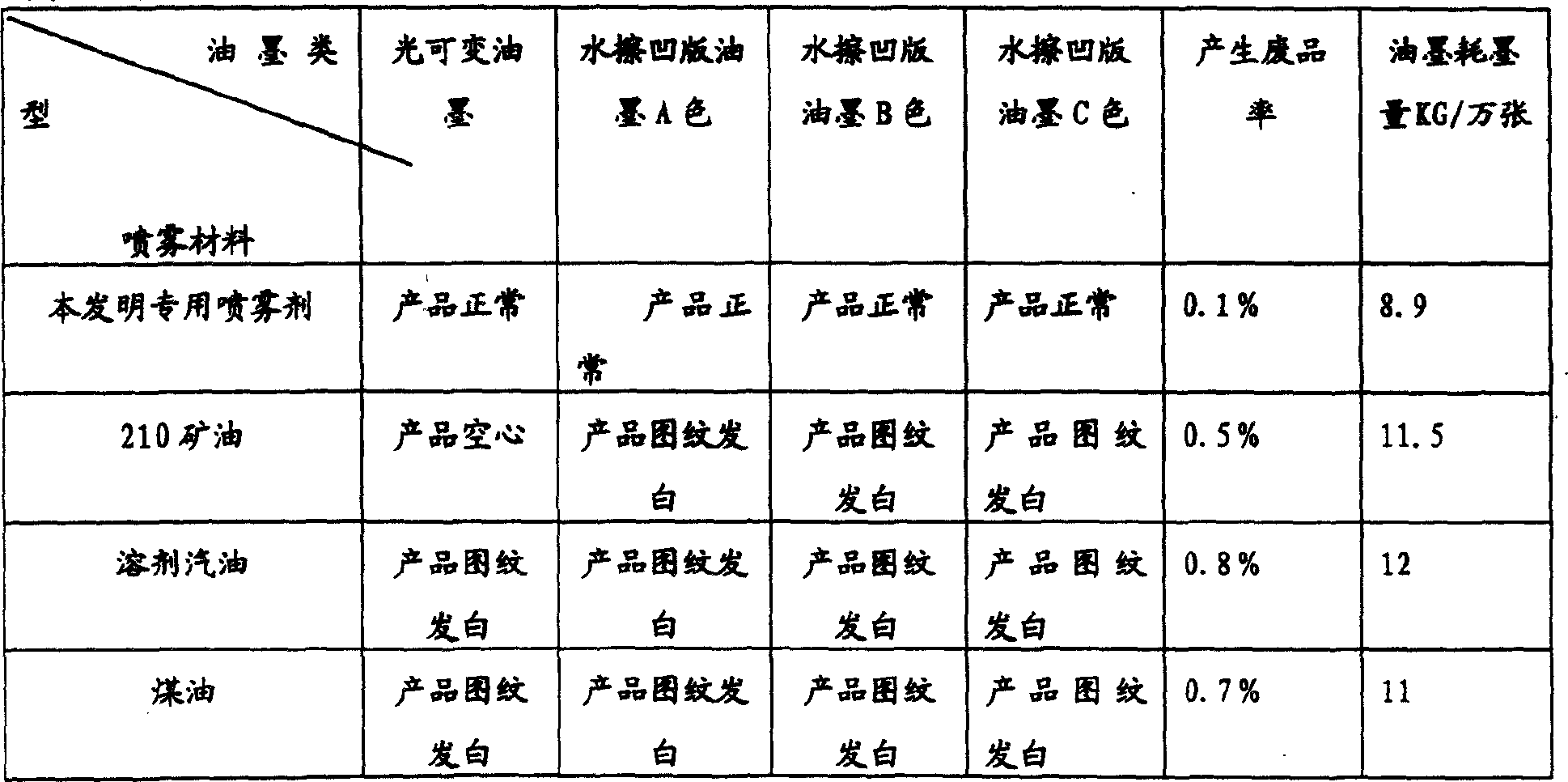

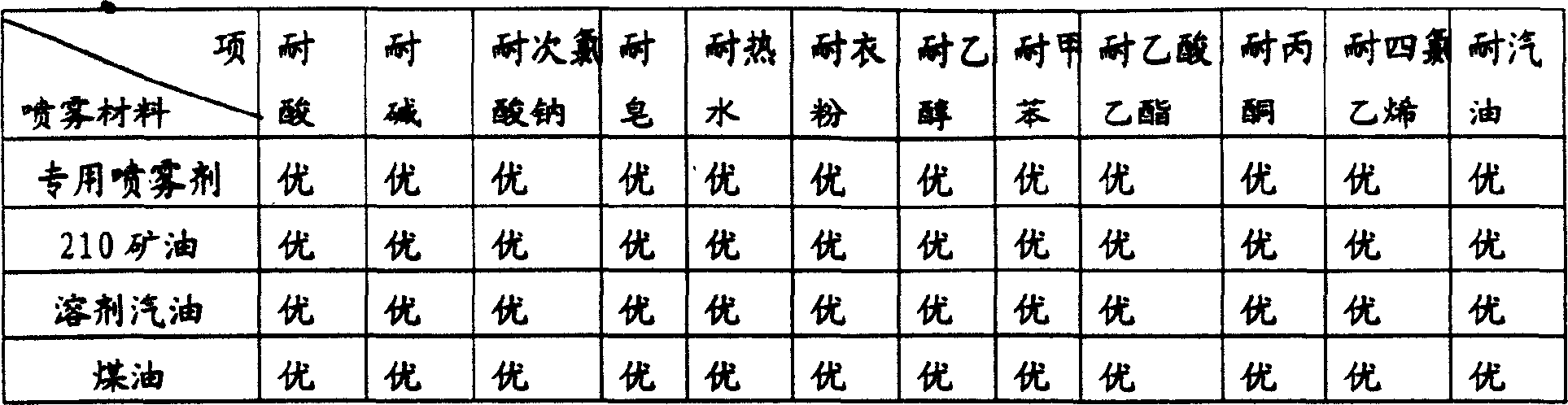

Method used

Image

Examples

Embodiment 1

[0022] High-speed water wipe gravure printing machine ink fountain special spray ink stabilizer, its composition ratio is: methyl carbitol 92.5 parts, surfactant 1.4 parts, water 3.8 parts, linseed oil 1.1 parts, surfactants are selected from ten Sodium Dialkyl Sulfonate.

Embodiment 2

[0024] High-speed water wipe gravure printing machine ink fountain special spray ink stabilizer, its composition ratio is: methyl carbitol 96.5 parts, surfactant 1.6 parts, water 4.2 parts, No. 6 linseed oil 4.5 parts, surfactant selection From Sodium Lauryl Sulfate.

Embodiment 3

[0026] High-speed water-rubbing gravure printing machine ink fountain special spray ink stabilizer, its composition ratio is: 94 parts of methyl carbitol, 1.5 parts of surfactant, 4.0 parts of water, 3 parts of No. 8 linseed oil, optional surfactant From Sodium Lauryl Sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com