Mesoporous Mn/Al oxide catalyst, and its preparation method and use

A mesoporous alumina and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of no porous structure, uneven catalyst dispersion, large particles, etc. achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

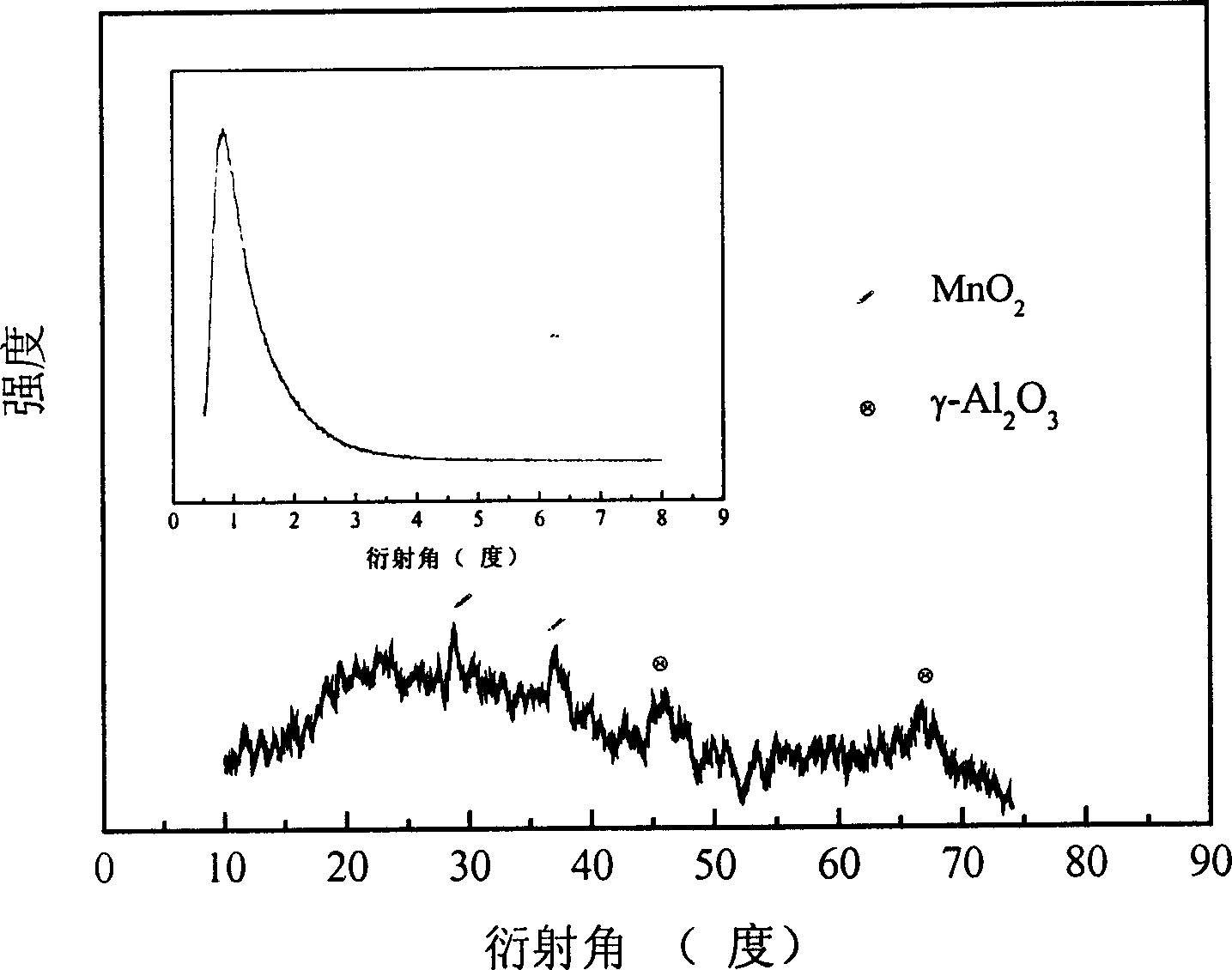

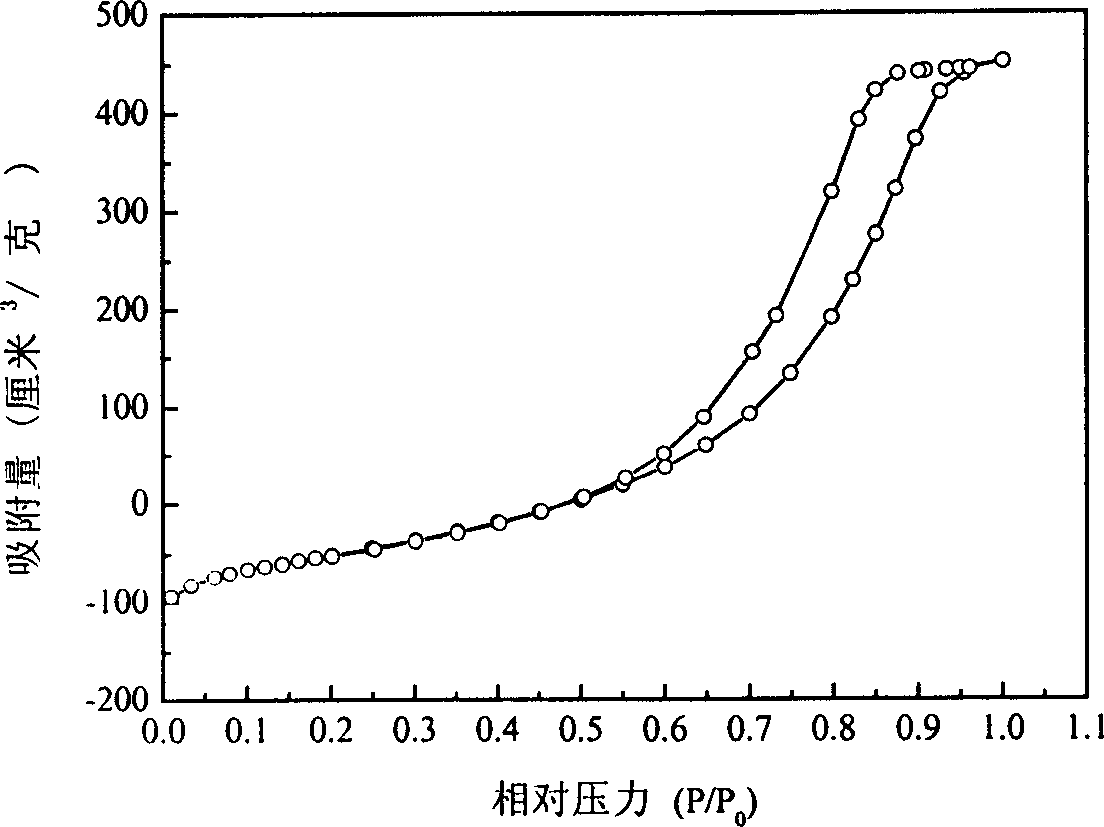

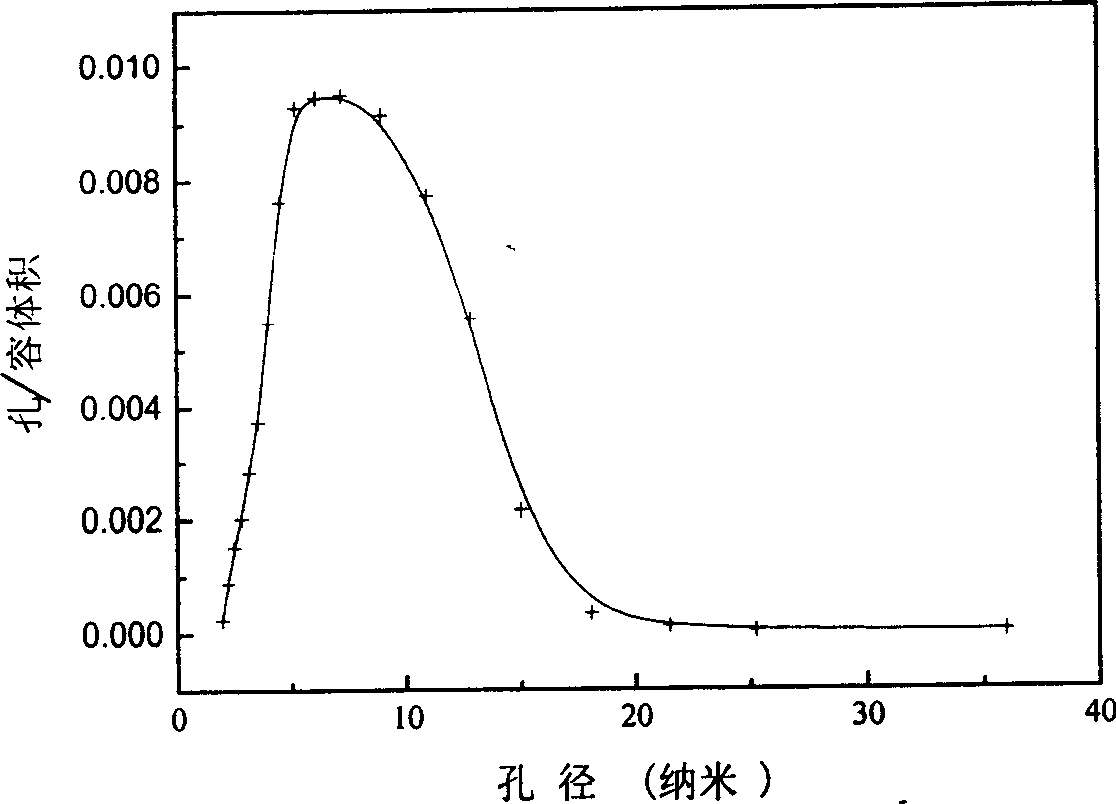

[0024] Example 1: Preparation of mesoporous alumina MSU-γ(1)

[0025] Weigh 37.53 grams of Al(NO 3 ) 3 ·6H 2 Add 38.5 grams of water to the metal nitrate of O, mix well, add nonionic surfactant triblock copolymer ((EO) 19 (PO) 70 (EO) 19 , P84, the molecular weight is 4400), so that Al / surfactant = 100; the solution was stirred at 40 ° C for 40 h, then heated to 70 ° C and continued to stir for 12 h, at 70 ° C, NH 3 ·H 2 O until pH = 8, aged for 12 h, moved to a stainless steel kettle, and crystallized at 100 ° C for 24 h; the precipitate was filtered and washed until the pH of the filtrate = 7, and the obtained filter cake was dried at 100 ° C under air atmosphere for 24 h -48h, the precursor with boehmite structure is obtained, which is denoted as MSU-S / B; the precursor is put in a tube furnace, fed with air, and the temperature is programmed to 325°C, roasted for 3h, and then programmed to 500°C for 3h , the heating rate is 2°C / min, and the mesoporous alumina is obta...

example 2

[0026] Example 2: Preparation of mesoporous alumina MSU-γ(2)

[0027] Weigh 37.53 grams of Al(NO 3 ) 3 ·6H 2 Add 38.5 grams of water to the metal nitrate of O, mix well, add nonionic surfactant triblock copolymer ((EO) 20 (PO) 70 (EO) 20 , P123, the molecular weight is 5800), so that Al / surfactant=10: the solution was stirred at 50°C for 30h, then heated to 90°C and continued to stir for 6h. At 45°C, see Example 1 for other conditions, the obtained The specific surface area of the product is 335m 2 / g.

example 3

[0028] Example 3: Preparation of mesoporous alumina MSU-γ(3)

[0029] Weigh 37.53 grams of Al(NO 3 ) 3 ·6H 2 Add 38.5 grams of water to the metal nitrate of O, mix well, add nonionic surfactant triblock copolymer ((EO) 19 (PO) 30 (EO) 19 , P65, molecular weight 2900), so that Al / surfactant=60; the solution was stirred at 50°C for 30h, then heated to 70°C and continued to stir for 6h. At 70°C, see Example 1 for other conditions, the obtained product Specific surface is 309m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com