Solid-state imaging device and manufacturing method therefor

A technology of solid-state imaging components and manufacturing methods, which is applied in the direction of electric solid-state devices, optical components, electrical components, etc., and can solve the problems of reduced saturation, large distance, and reduced image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

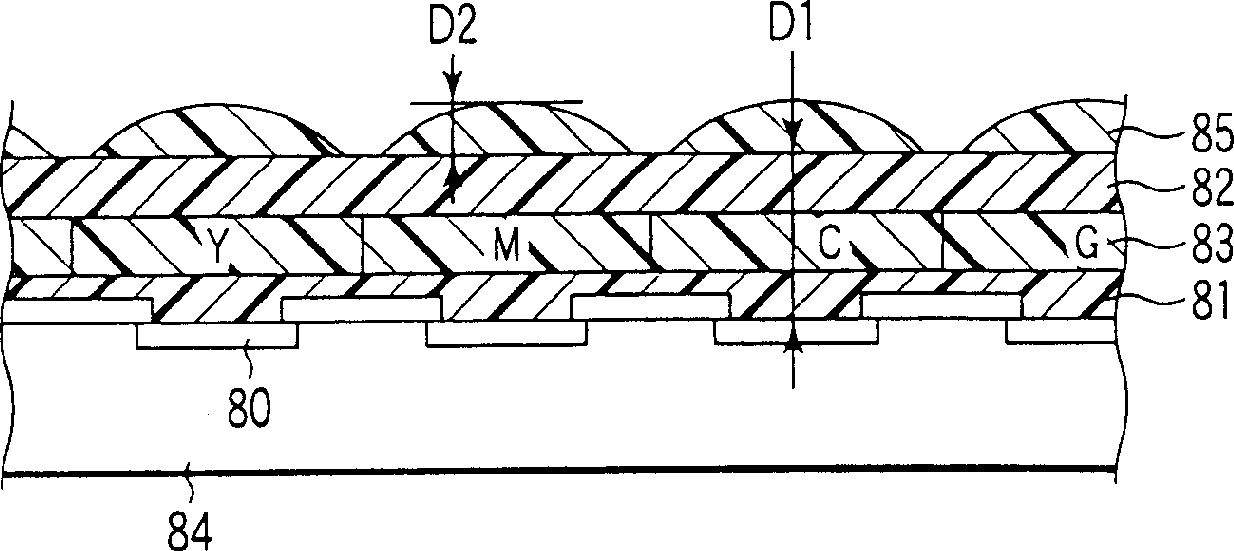

[0036] Figure 2A A plan view of the solid-state imaging device 1 of the first embodiment is shown. also, Figure 2B A sectional view along line A-A of FIG. 1 is shown. First, refer to Figure 2A and Figure 2B Next, the configuration of the solid-state imaging device 1 will be described.

[0037] Such as Figure 2A , Figure 2B As shown, the solid-state imaging device 1 includes a microlens 10 , a semiconductor substrate 11 , a photoelectric conversion element 13 , a light shielding layer 16 , and a planarization layer 15 .

[0038] The semiconductor substrate 11 is a substrate for mounting the photoelectric conversion element 13 and the like. The photoelectric conversion element 13 converts light incident through the microlens 10 into charges. The flattening layer 15 flattens the mounting surface of the microlens 10 .

[0039]The microlens 10 has a hemispherical shape, and has a hemispherical transparent resin upper layer 10 a forming the upper portion of the lens 1...

no. 2 Embodiment approach

[0072] Figure 4 It is a plan view of the solid-state imaging device 20 of the second embodiment. Figure 5A shows the edge of the solid-state imaging device 20 Figure 4 Sectional view of line A-A. Such as Figure 5A As shown, the solid-state imaging element 20 includes a semiconductor substrate 11 , a photoelectric conversion element 13 , a microlens 10 , a blocking layer 16 , and a planarization layer 15 .

[0073] The microlens 10 has a transparent resin upper layer 10a and a colored lower layer 10b. An infrared absorption function can be imparted to the transparent resin upper layer 10 a and the planarization layer 15 . Generally, an infrared cut filter with a thickness of about 2mm is included in the optical system of a solid-state imaging device for a digital camera or a mobile phone, but by imparting an infrared absorption function to the transparent resin upper layer 10a or the planarizing layer 15, remove the infrared cut filter.

[0074] In addition, if Figu...

no. 3 Embodiment approach

[0113] Figure 9 The edge of the solid-state imaging device 30 of the third embodiment is shown Figure 4 Sectional view of line A-A. First, refer to Figure 9 The configuration of the solid-state imaging device 30 will now be described.

[0114] Such as Figure 9 As shown, the solid-state imaging device 30 includes a microlens 10 , a semiconductor substrate 11 , a photoelectric conversion element 13 , a planarization layer 15 , a blocking layer 16 , and an external resin layer 31 .

[0115] Such as Figure 9 As shown, the thickness T5 of the microlens 10 is the sum of the thickness T1 of the transparent resin upper layer 10a and the thickness T4 of the colored lower layer forming a part of the microlens (the depth to the lens-shaped notch portion of the colored lower layer 10b) (T5 =T1+T4).

[0116] The specific ideal thickness T1 of the transparent resin upper layer 10a, the ideal thickness T2 of the colored lower layer 10b, and the ideal area of the interface betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com