Hardcoat film, antireflection film and equipment for display

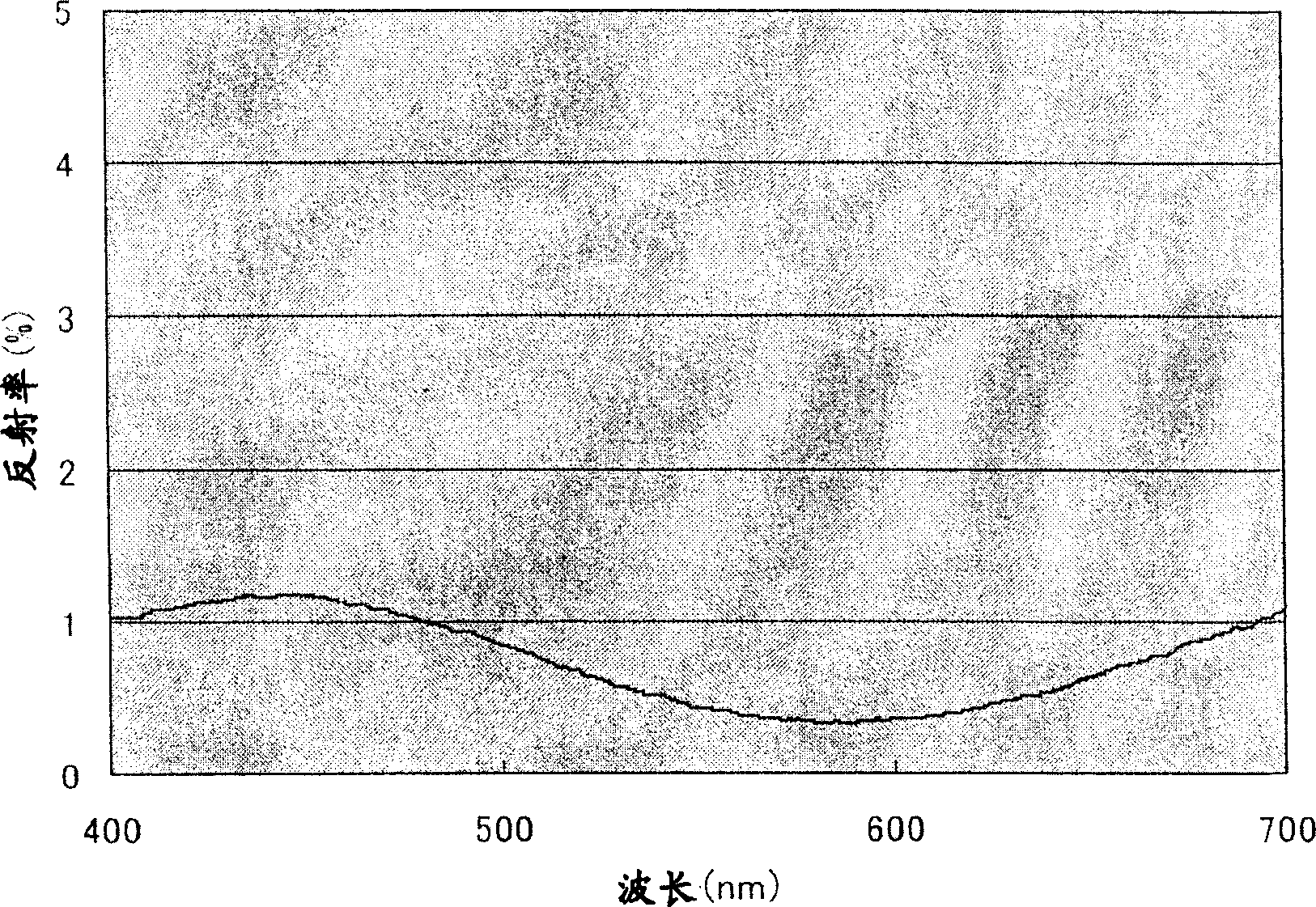

一种硬涂层、防反射的技术,应用在涂层、辨认装置、分层产品等方向,能够解决表面耐擦伤性达不到、反射率降低不充分等问题,达到生产性优良、粘合性良好、表面反射率低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] An example of the preparation method of the hard coat layer of the present invention is described below, although in this example, polyethylene terephthalate (hereinafter referred to as PET) is used as an example to illustrate the base film, but the present invention It is not limited to this.

[0090] PET granules (intrinsic viscosity 0.62 dl / g) containing 0.2% by weight of silica granules with an average particle diameter of 0.3 μm were vacuum-dried at 180° C. for about 2 hours to sufficiently remove moisture, and then supplied to an extruder, and heated at 260 to It is melt-extruded at a temperature of 300°C and formed into a sheet from a T-shaped die. The flaky material thus obtained is cooled and solidified on a mirror-surfaced cooling roller to obtain an unstretched film. At this time, in order to improve the adhesiveness with the casting drum, it is preferable to use an electrostatic application method. Then, the obtained unstretched sheet is stretched 2 to 5 t...

Embodiment 1

[0212] Polyethylene terephthalate (hereinafter referred to as PET) ( The chips with an intrinsic viscosity of 0.62 dl / g) were sufficiently vacuum-dried at 180°C, supplied to an extruder, melted at 285°C, and extruded in a sheet form from a T-shaped die. The extruded sheet was wound and solidified on a mirror casting drum with a surface temperature of 20°C by an external electrostatic molding method to obtain an unstretched film. The obtained unstretched sheet was stretched 3.0 times in the longitudinal direction on a group of rolls heated to 105° C. to obtain a uniaxially stretched film. Next, on one side of the monoaxially stretched film, the above-mentioned coating agent A was applied to a thickness of 20 μm by die coating. Then, both ends of the film coated with the coating agent A were clamped with clips, introduced into a preheating zone at 90°C, and then stretched 3.3 times in the width direction in a heating zone at 100°C. Furthermore, heat treatment was performed for...

Embodiment 2

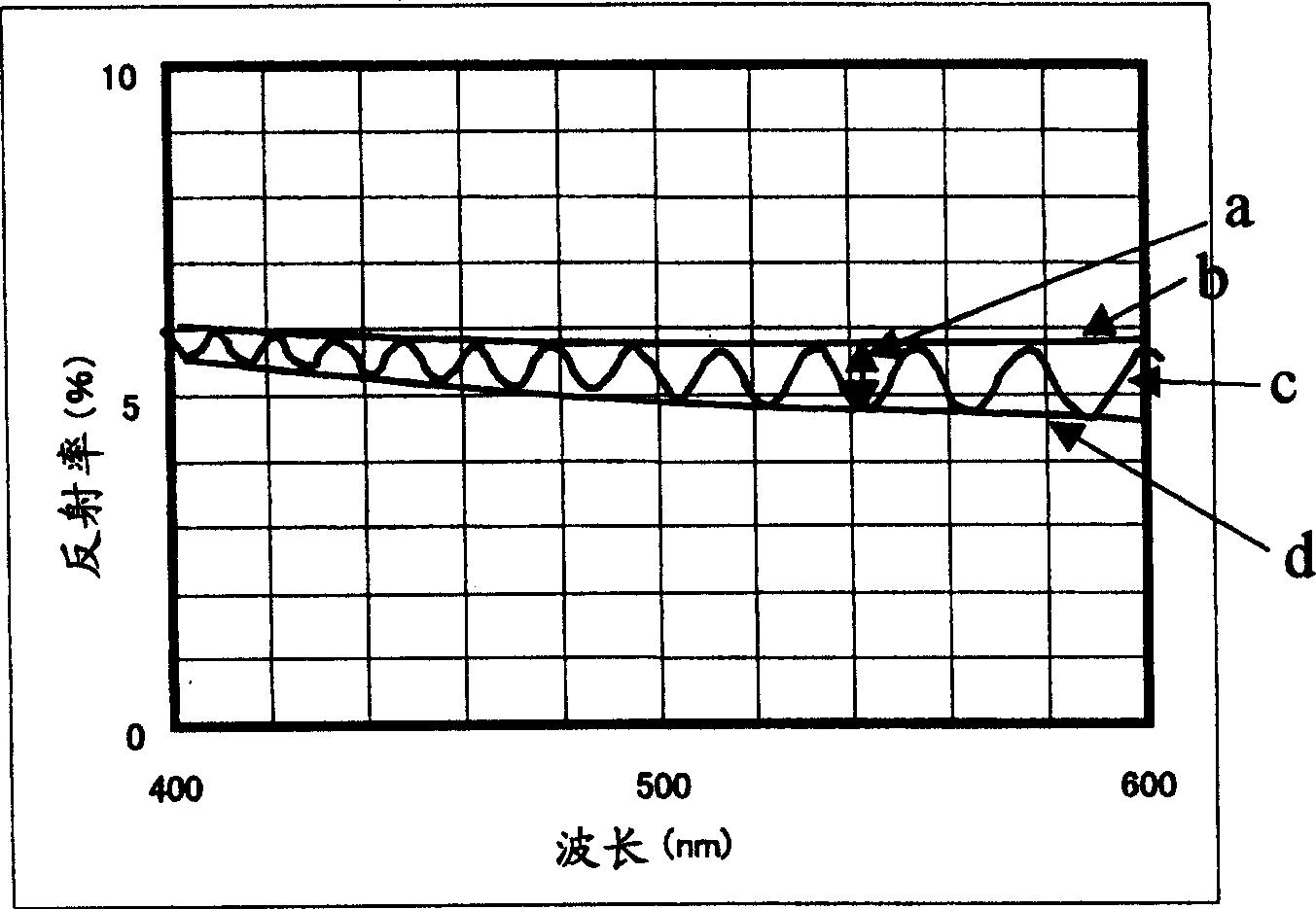

[0220] In Example 1, a hard coat film was produced in the same manner as in Example 1, except that the coating material D in which the polyisocyanate was changed was used instead of the coating material A. The results are shown in Table 1. As shown in Table 1, it shows that the average fluctuation amplitude is 0.2%, the surface reflectance is 5.2%, the turbidity is 0.8%, the adhesion is B under normal conditions, the adhesion under wet heat is B, and the abrasion resistance is 3kg / cm 2 , the pencil hardness is 3H, there is no rainbow pattern, and the visibility is excellent characteristics of A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com