Electroluminescence panel and manufacturing process therefor

A technology of electroluminescence and manufacturing method, which is applied in electroluminescence light source, semiconductor/solid-state device manufacturing, light source and other directions, and can solve problems such as saddle deformation of glass cover sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

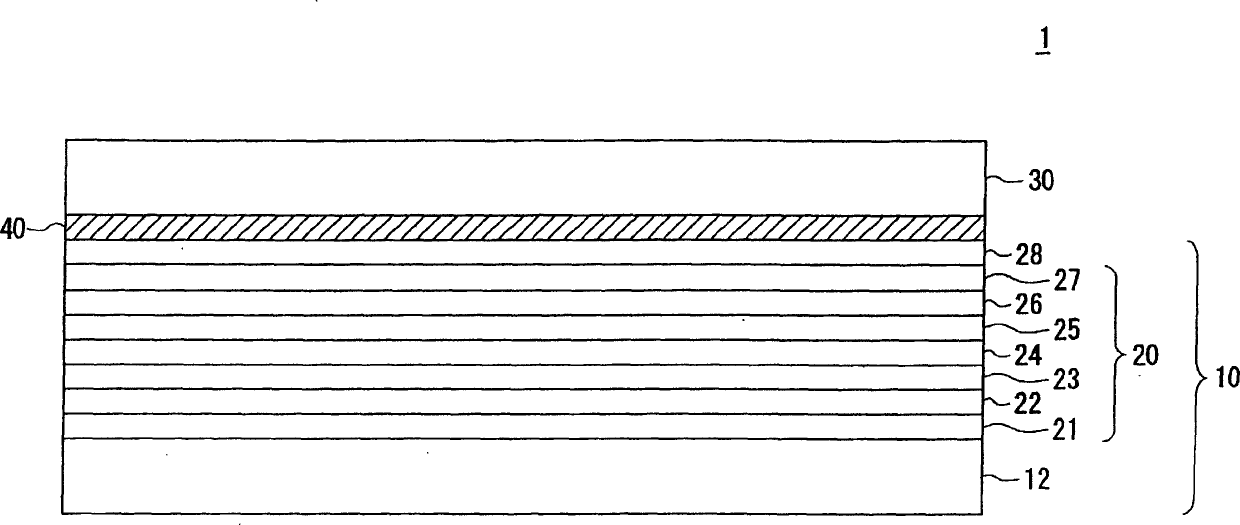

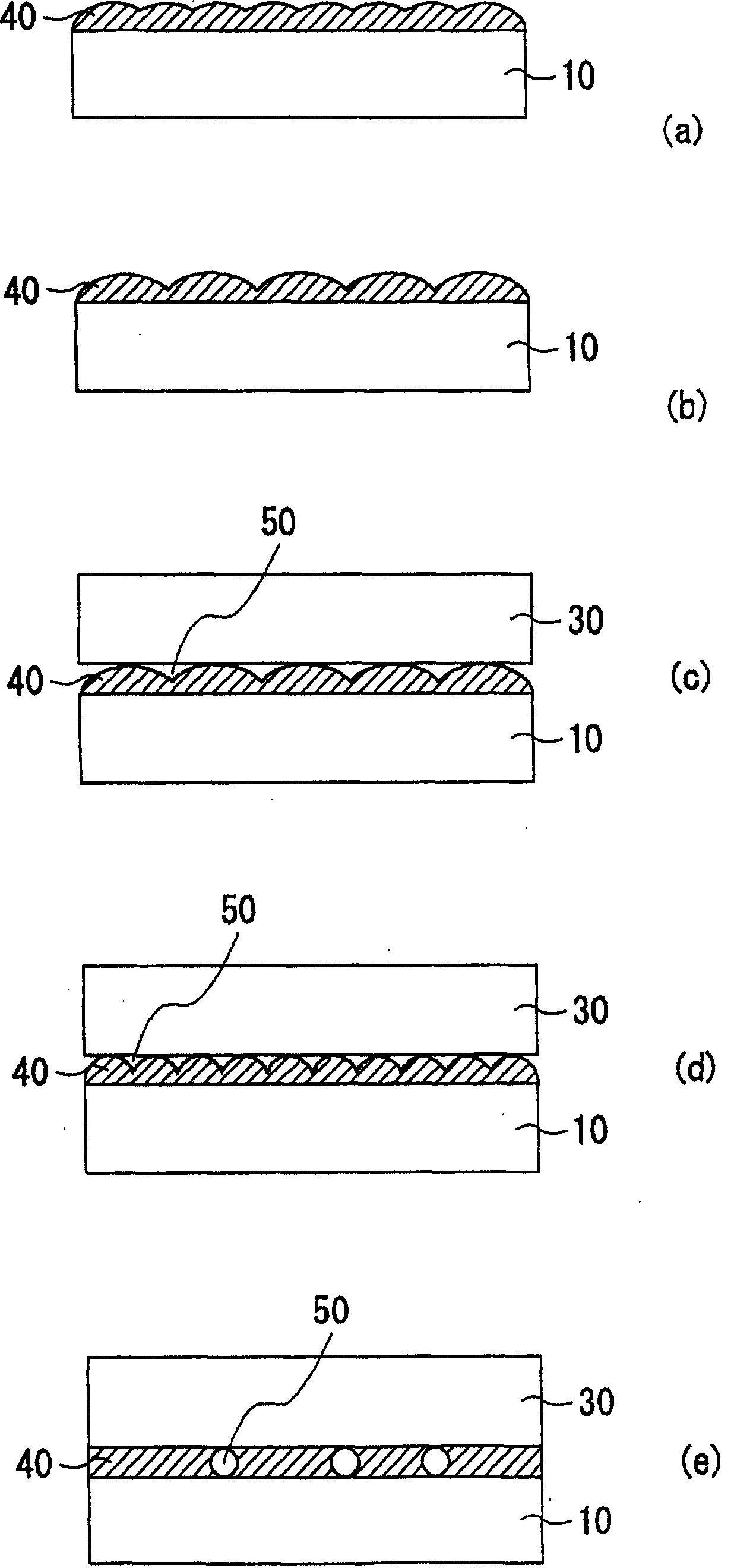

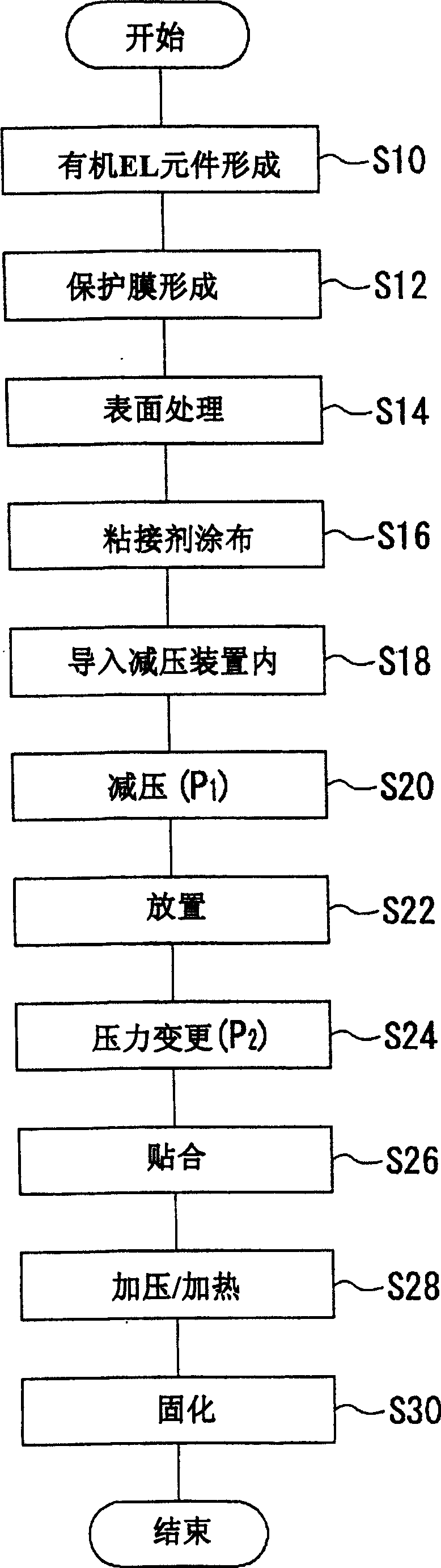

[0050]On the organic EL element 20 formed into a film on the glass substrate 12 , a protective film 28 made of an inorganic layer of SiN is laminated to manufacture the element substrate 10 . The element substrate 10 is 2.2 inches in length x 2.2 inches in width; the number of pixels is 220 pixels in length x 176 pixels in width. In the horizontal direction, a total of three types of pixels R, G, and B are arranged on one pixel. The size of the pixel is 0.198 mm in the vertical direction as the long side, and 0.066 mm in the horizontal direction as the short side in each of the R, G, and B pixels. The surface of the element substrate 10 is subjected to plasma treatment with argon. At this time, the contact angle is 10° or less. An ultraviolet UV-curable epoxy resin with a viscosity of 2 Pascal seconds is coated on the surface of the element substrate 10 by screen printing to improve uniformity. The element substrate 10 coated with the adhesive 40 is placed in the chamber of...

Embodiment 2

[0052] In Example 2, surface treatment was performed on both the element substrate 10 and the sealing substrate 30 . In addition, the organic EL panel 1 was manufactured in the same procedure as in Example 1. The number of tiny spaces in the organic EL panel 1 manufactured in this embodiment is 6 per diagonal inch with a diameter of 0.2 mm or less.

Embodiment 3

[0054] In Example 3, in the procedure shown in Example 1, the surface treatment of the substrate was not performed, and in the bonding process, as shown by the solid line in FIG. substrate. The number of minute spaces of the organic EL panel 1 manufactured in this embodiment is 5 per 1 inch of the diagonal for those with a diameter of 0.2 mm or less.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com