Motor driving apparatus

A driving device and motor technology, which is applied in the direction of AC motor control, electronic commutation motor control, single motor speed/torque control, etc., can solve the problems of motor drive efficiency drop, converter circuit input power factor drop, etc., to achieve suppression Effects of waveform deformation, reduced impedance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0147] Embodiments of the present invention will be described below.

[0148] (Embodiment 1)

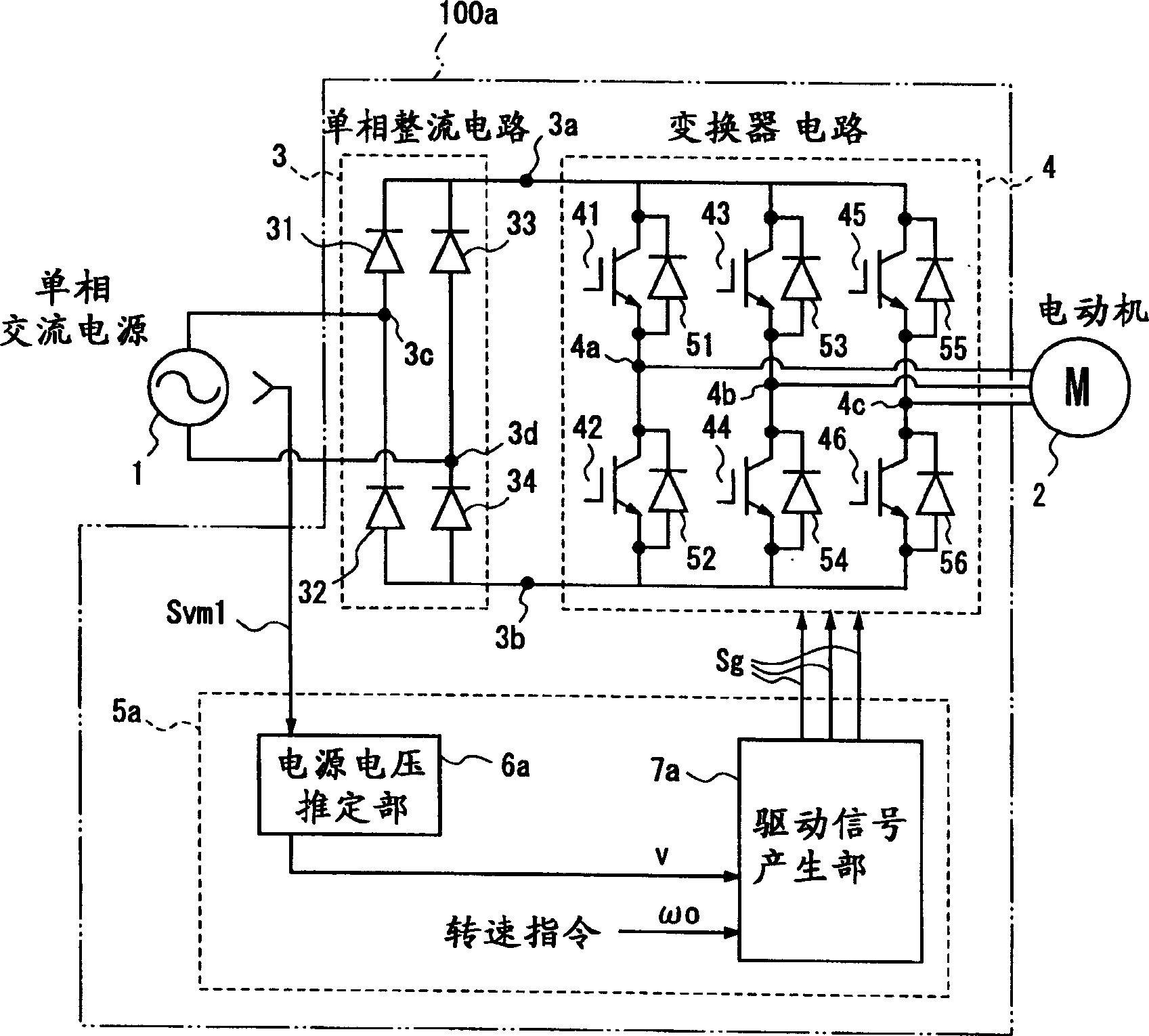

[0149] figure 1 It is a block diagram for explaining the motor driving device according to Embodiment 1 of the present invention.

[0150] The motor drive device 100a according to Embodiment 1 of the present invention uses a single-phase AC power supply 1 as an input and uses a three-phase AC output to drive a motor 2 at a desired frequency. In the first embodiment, the above-mentioned motors are referred to as induction motors, DC brushless motors, reluctance motors, etc., but are not limited to these types. In addition, here, the motor drive device 100a described above is a device that drives a motor of a compressor that circulates a coolant loaded in an air conditioner.

[0151] Hereinafter, the single-phase rectification circuit 3, the inverter circuit 4, and the inverter control unit 5a constituting the above-mentioned motor drive device 100a will be described in detail.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com