Spraying counteraction type steam turbine

A thrust-reversing, water-vapor technology, which is applied to thrust-reversing devices, mechanical equipment, machines/engines, etc., and can solve problems such as complex equipment structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

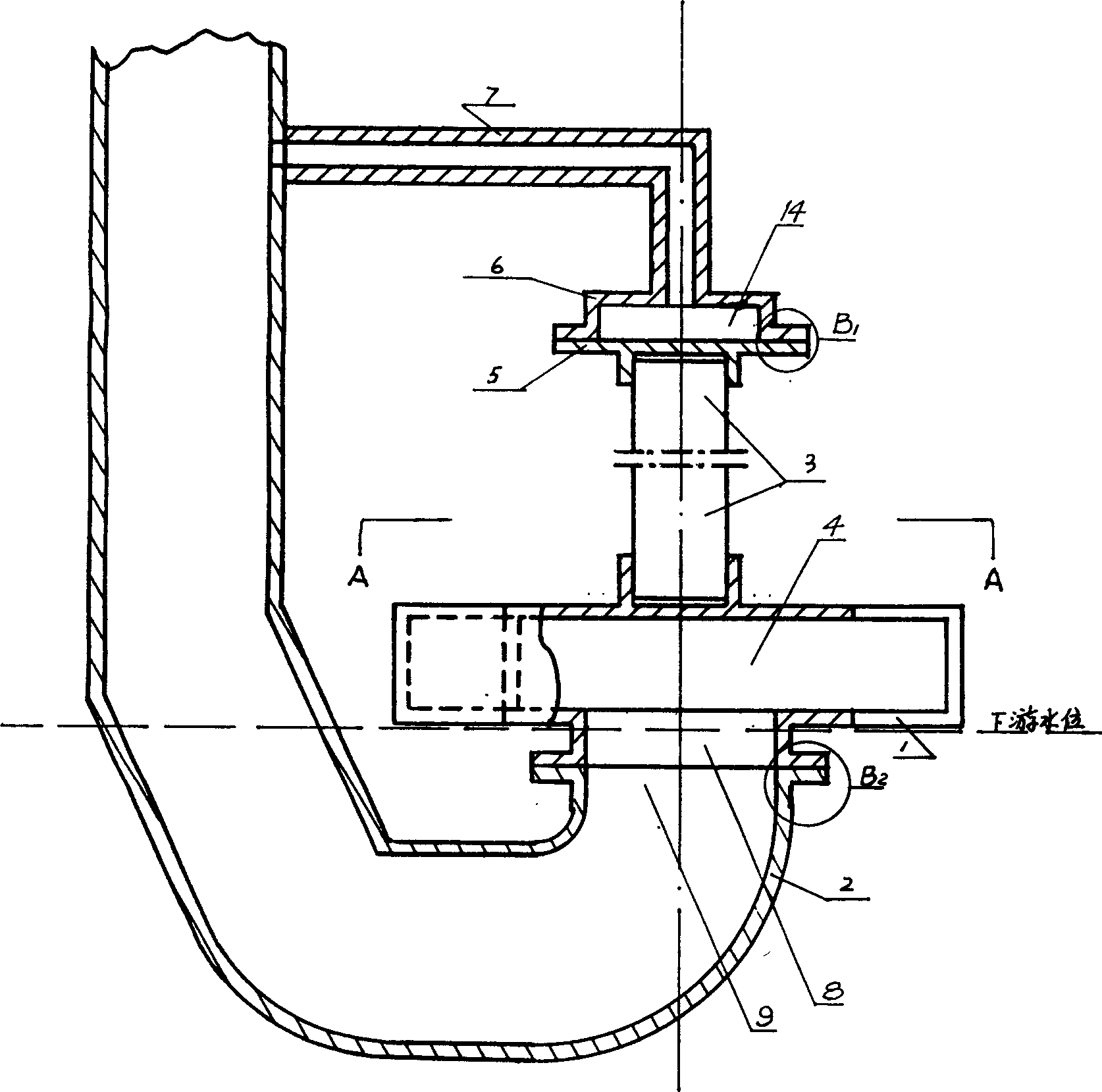

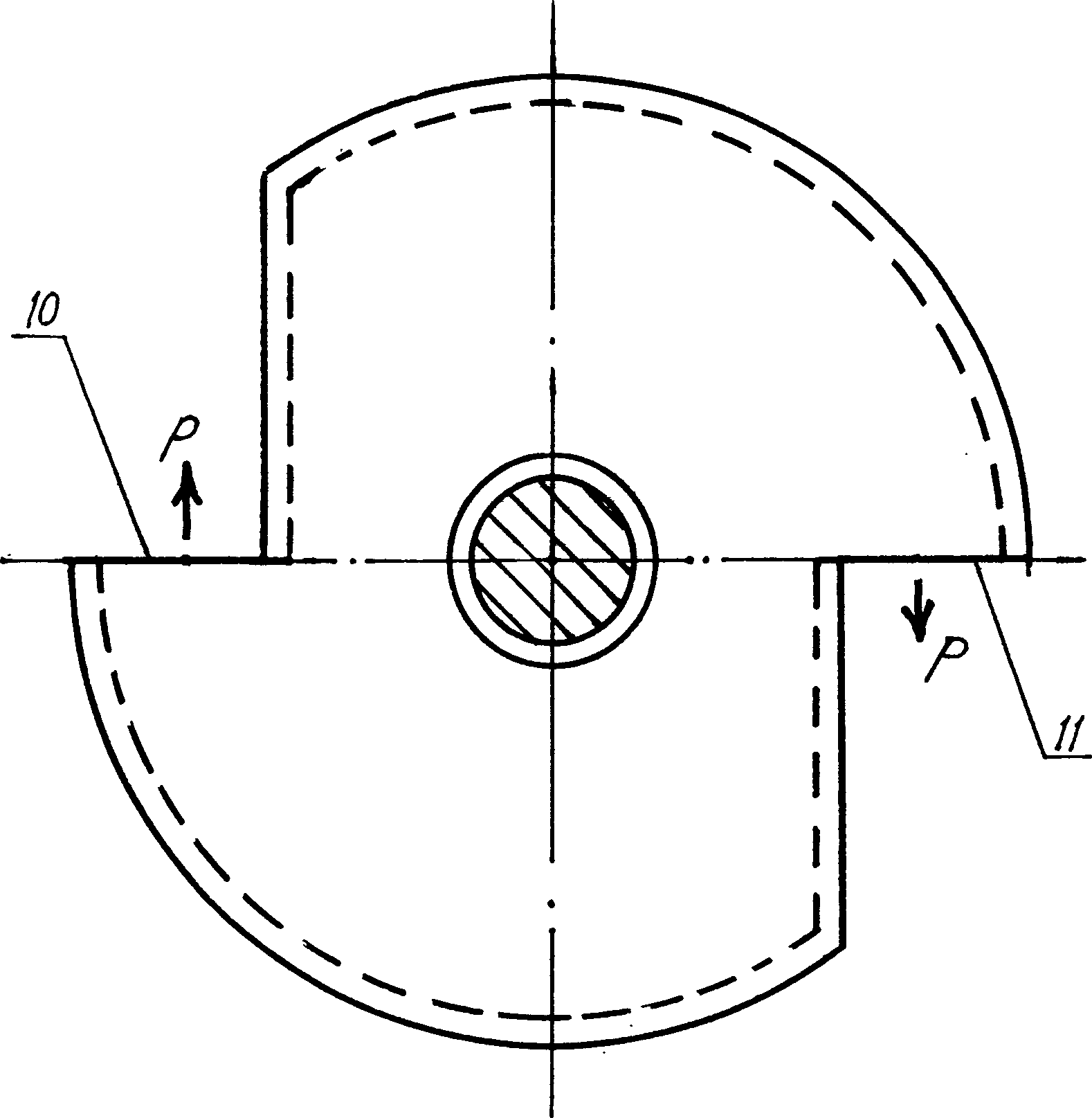

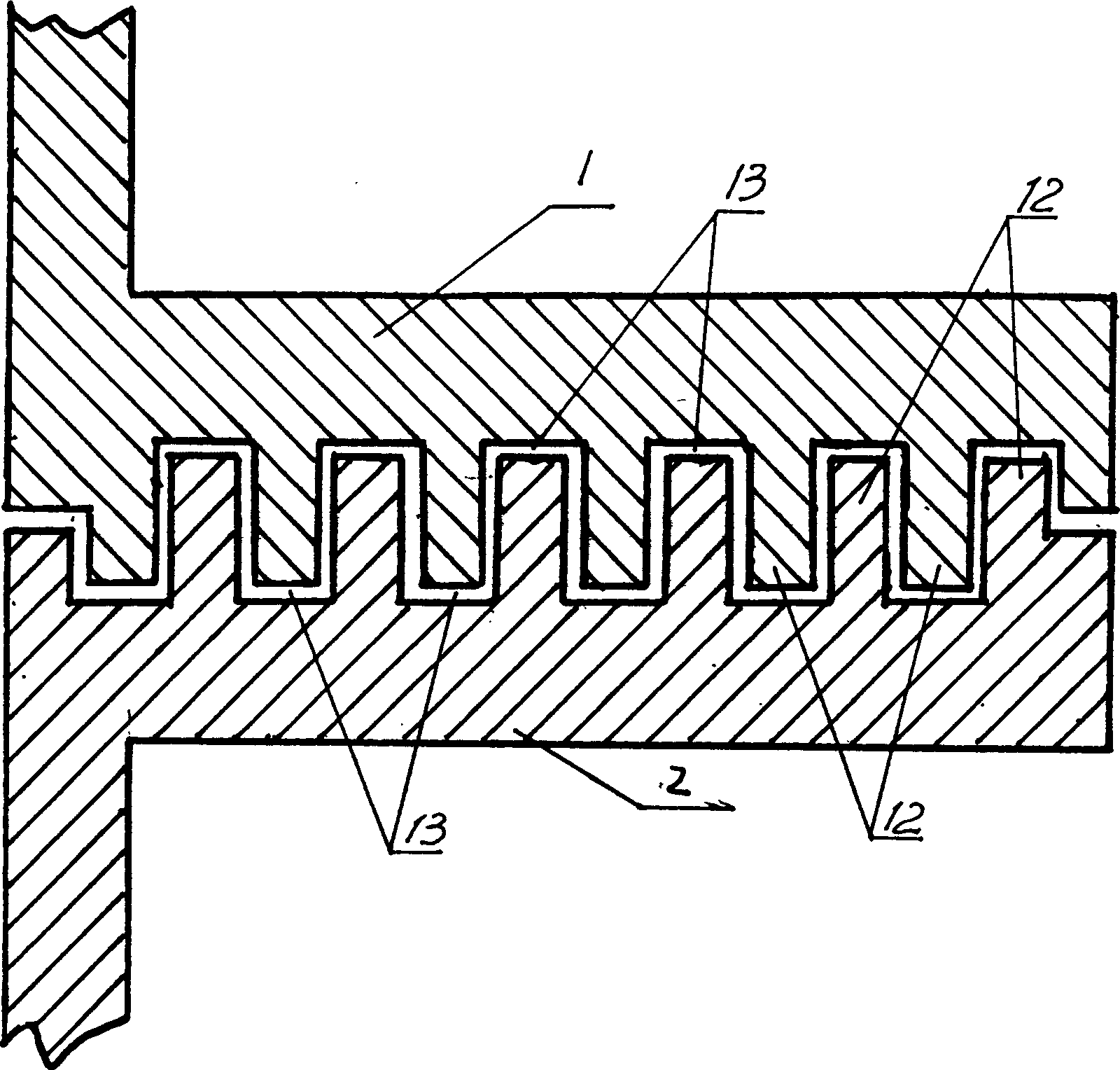

[0026] According to the device of the present invention of accompanying drawing and above-mentioned structure, design is water turbine, as figure 1 As shown, the wheel disc 1 is driven by the water head drop, and the rotor shaft 3 is the generator rotor (that is, the device of the present invention drives the generator to generate electricity), the water head drop is 3 meters, and the flow rate is 100 meters per minute 3 ,according to figure 1 The scale of the device shown is used to make the water turbine of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com